Three-color injection molding rotary hinge container

A technology for rotating hinges and containers, applied in the field of injection molding, can solve the problems of high cost, cumbersome manufacturing process, and gaps between the rotating shaft and the product, and achieve the effects of improving production efficiency, reducing costs, and reducing manual assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

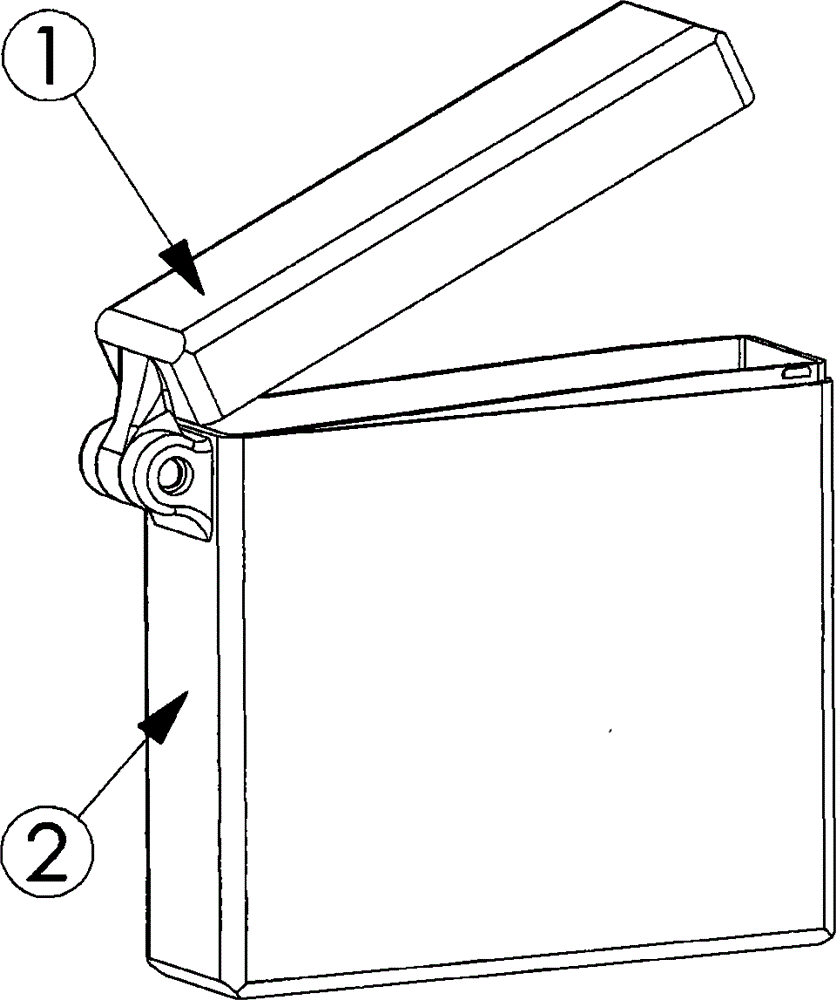

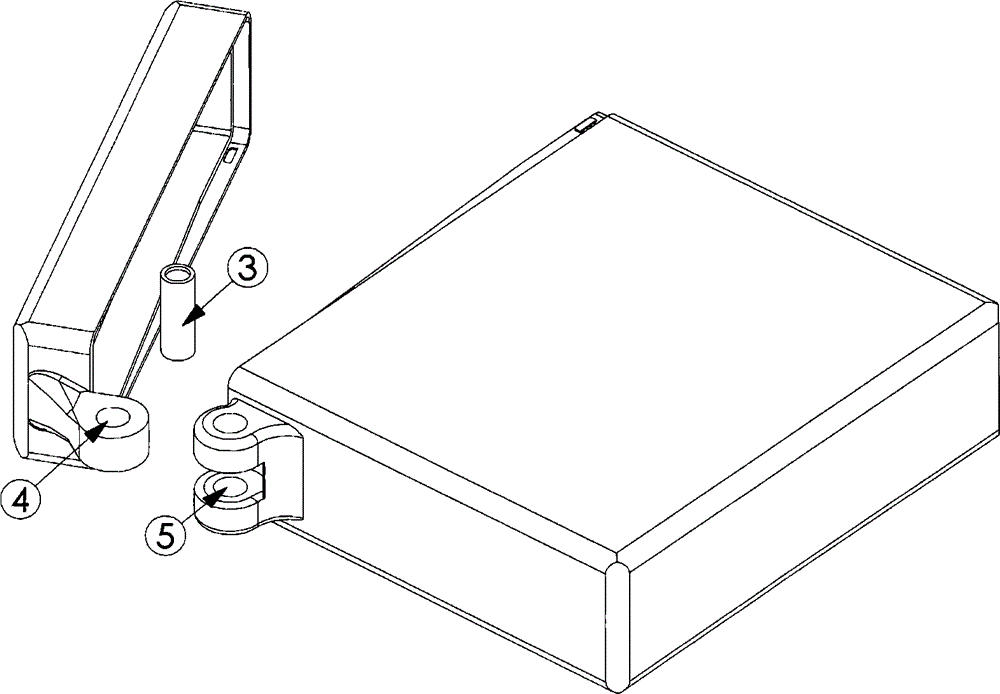

[0015] see figure 1 and 2 , Embodiment 1 of the present invention: a three-color injection molding rotary hinge container, including a cover 1, a bottom cover 2 and a rotating shaft 3: the cover 1 contains a ring structure 4, and the bottom cover 2 contains two ring structures 5. They are tightly matched with each other to form a cylindrical hollow structure, and the cylindrical hollow structure is formed into an integrated structure of the rotating shaft 3 after injection molding.

[0016] In this embodiment, the cover 1 is made of PC material.

[0017] In this embodiment, the bottom cover 2 is made of ABS material.

[0018] In this embodiment, the rotating shaft 3 is made of POM material.

Embodiment 2

[0019] Embodiment 2: An injection mold for preparing the three-color injection molded rotary hinge container of the above embodiment 1. The injection mold includes a cavity containing a surface cover 1 , a bottom cover 2 and a rotating shaft 3 in the injection mold. The injection mold for the three-color injection molding rotary hinge container is characterized in that a pendulum block is provided in the rear mold of the mold to assemble the face cover and bottom cover in the mold: the pendulum block is guided by a shaft on the mold opening float After the columbum is ejected, rotate it, and rotate the top cover in the mold to a proper position to assemble with the bottom cover. The assembled surface cover 1, bottom cover 2 and the hollowed-out position of the cylinder in the mold form the injection molding cavity of the rotating shaft 3, and the mold is closed and injected after the buoy is rotated 180 degrees. After injection molding, the rotating shaft 3 is integrated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com