Built-in freezer lid

A built-in freezer technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of many freezer lid parts, poor airtightness of the freezer, and many assembly processes, so as to reduce manual assembly processes, Improved thermal insulation effect and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention is specifically described below in conjunction with accompanying drawing:

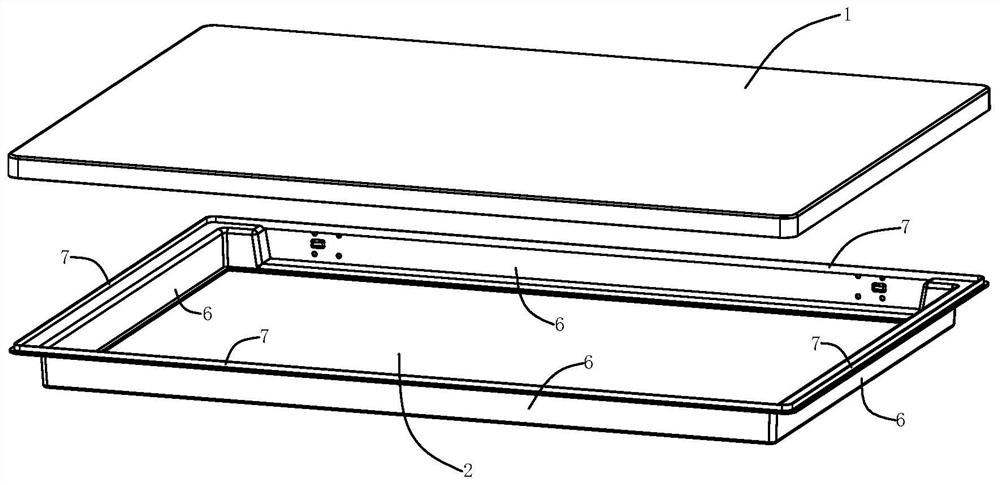

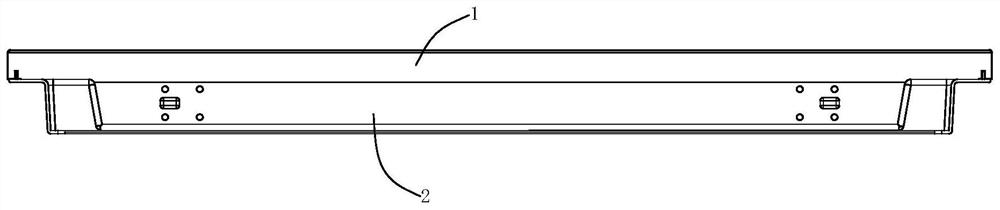

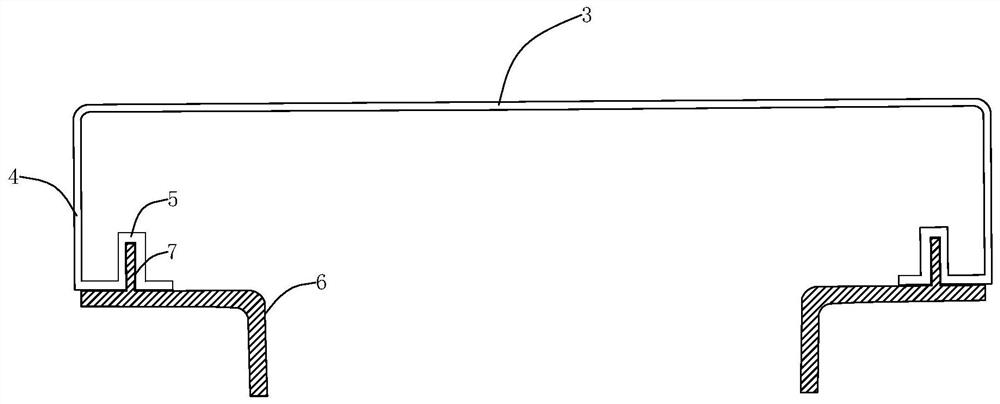

[0017] combine Figure 1 to Figure 4 , a built-in freezer box cover, including a cover body 1, an end stopper 2 and an end stop seal, the cover body 1 includes a cover plate 3, a vertical plate 4 and a clip 5. Wherein the cover body 1 is processed by a sheet metal integral forming process, and the specific cover plate 3 is square, and the specific size depends on the size of the freezer used. The cover plate 3 is connected with a vertically downward vertical plate 4 around its periphery. The four vertical plates 4 are all perpendicular to the cover plate 3 . Clamping parts 5 such as Figure 4 As shown, the longitudinal section of the clamping member 5 is in the shape of a few characters, and the inner space of the several-shaped clamping member 5 forms a card slot 8, and the lower ends of the four vertical plates 4 are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com