Integrated drive module with energy conversion function and manufacturing method thereof

A drive module, energy conversion technology, applied in color TV parts, TV system parts, TV and other directions, can solve the problems of ineffective reduction, size, thickness limitation, impact on yield, etc., to reduce manual assembly process, reduce the overall size and thickness, and improve the effect of product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

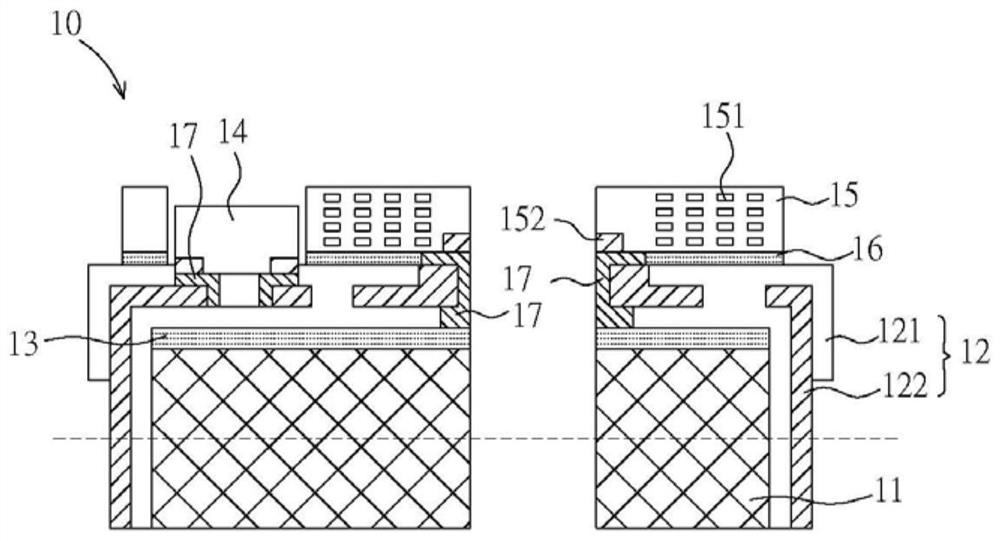

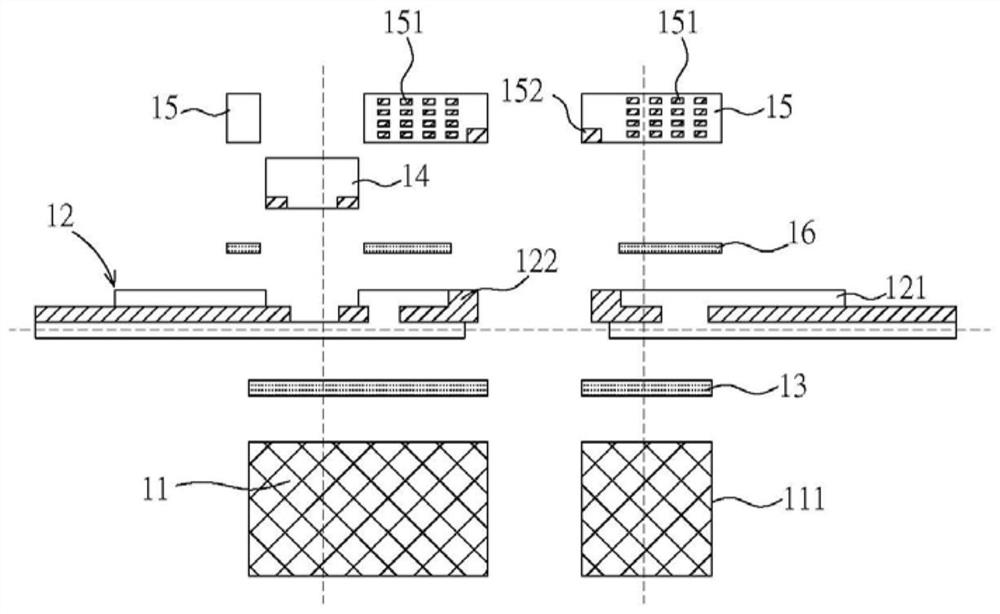

[0070] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. In the following description, a lot of specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, and those skilled in the art can do it without departing from the meaning of the present invention. By analogy, the present invention is therefore not limited to the specific examples disclosed below.

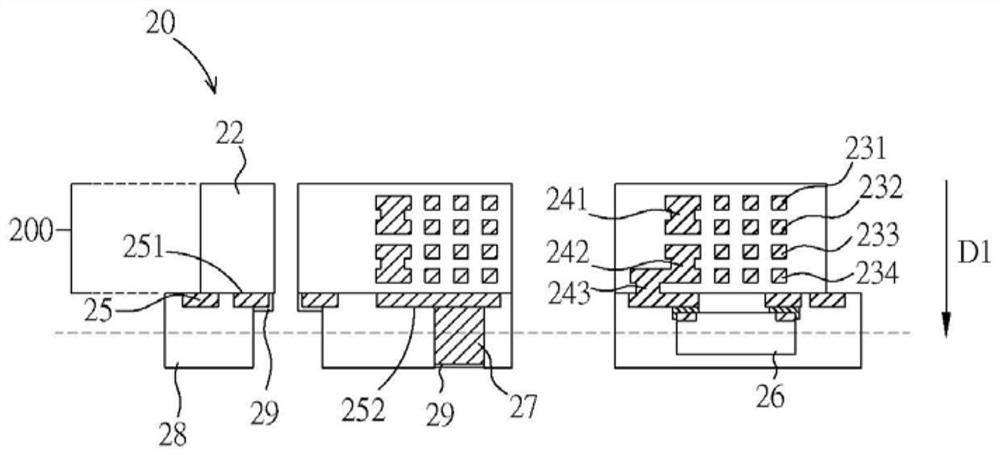

[0071] Please refer to figure 2 As shown, an integrated drive module 20 with energy conversion function according to a preferred embodiment of the present invention includes a patterned conductive circuit layer 25, an integrated electromagnetic induction component layer 200, and a second dielectric layer 28 , an embedded component 26 and a conductive component 27 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com