Two-way tire pressure monitoring system of single LF transmitting part

A tire pressure monitoring system and component technology, applied in tire measurement, vehicle parts, tire parts, etc., can solve the problems of long positioning time, uncontrollable measurement timing, and complex positioning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

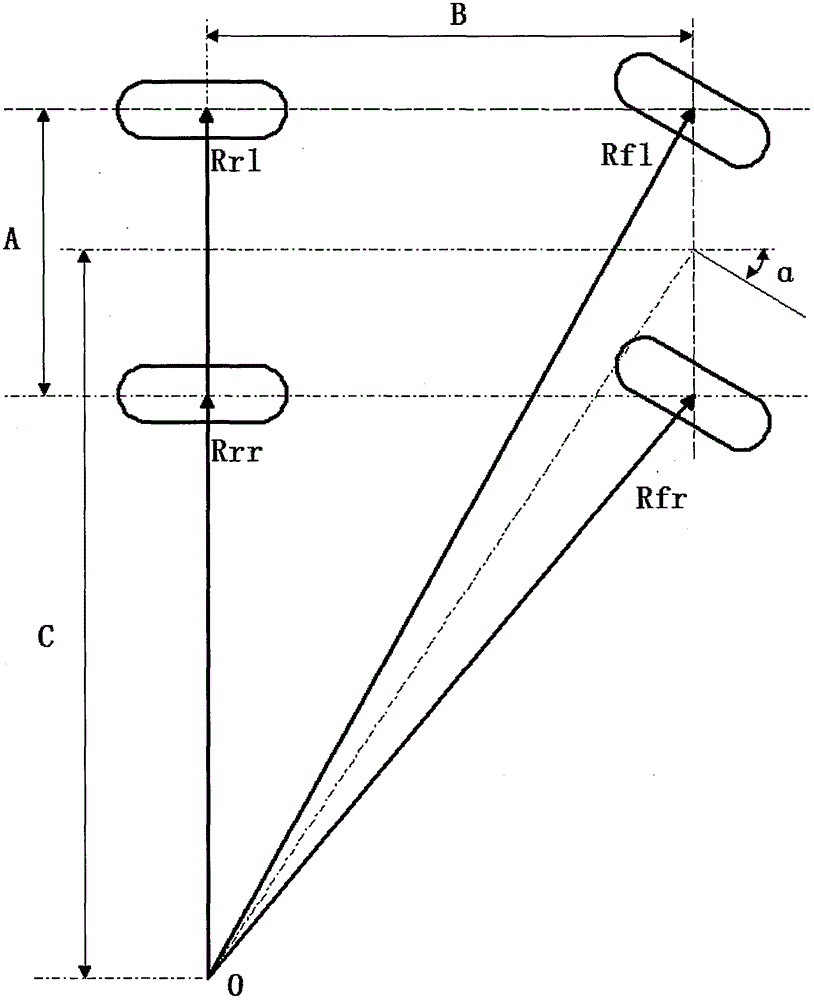

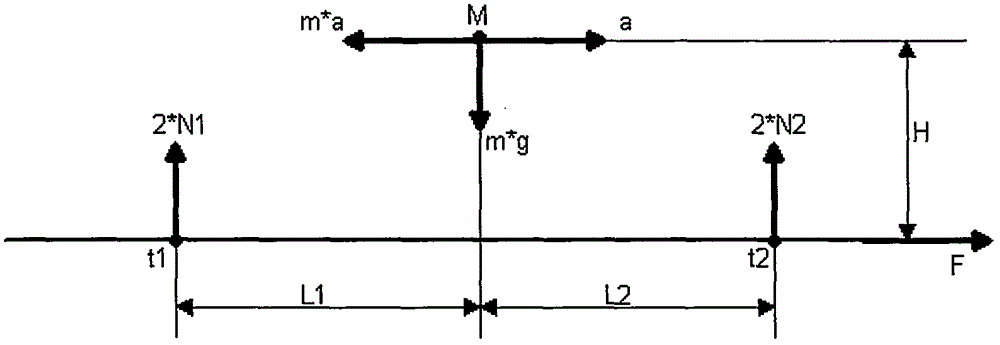

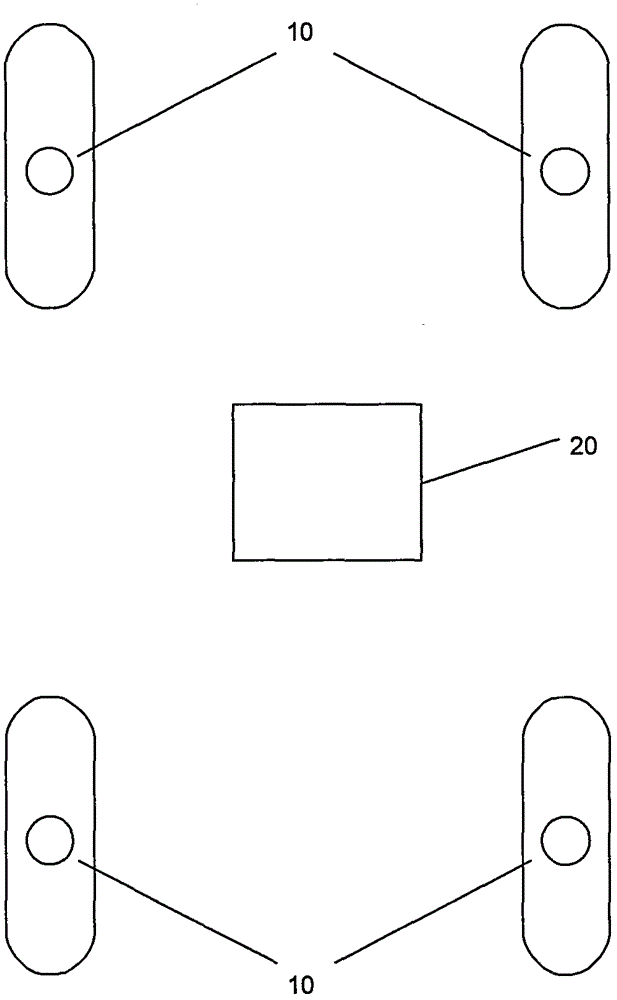

[0097] The present invention is described in detail below with specific embodiments, image 3 It is a preferred structure of a two-way tire pressure transmission monitoring system with a single LF emitting component, which includes: a control terminal 20, and four tire pressure sensors 10 installed on tires.

[0098] The structure of the control terminal 20 is as Figure 4As shown, it includes MCU200, LF transmitting part 201, RF receiving part 202, and bus interface 203 of the vehicle; For receiving the measurement data of each tire pressure sensor, the MCU 201 is connected with the bus interface 203 of the vehicle for obtaining the vehicle running status and transmitting the measurement results, and the MCU 200 is also used for controlling the work of the various components.

[0099] Each component of the control terminal 20 is installed in a housing, and is fixed on the chassis below the gear of the vehicle at the same distance as possible from the four tires. The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com