Automatic feeding device of automatic capping machine for electronic connectors

An electronic connector, automatic feeding technology, applied in vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of manual installation of end caps, waste of resources, and high labor costs, reducing costs and improving efficiency. , Smooth and accurate feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples.

[0023] The connector mentioned in this embodiment is actually the same part as the electronic connector 11, and both ends of the connector need to be covered with end caps during heat treatment. The upstream end and downstream end mentioned in this embodiment are determined according to the conveying direction of the electronic connector 11 , the position passing first is upstream, and the position passing later is downstream.

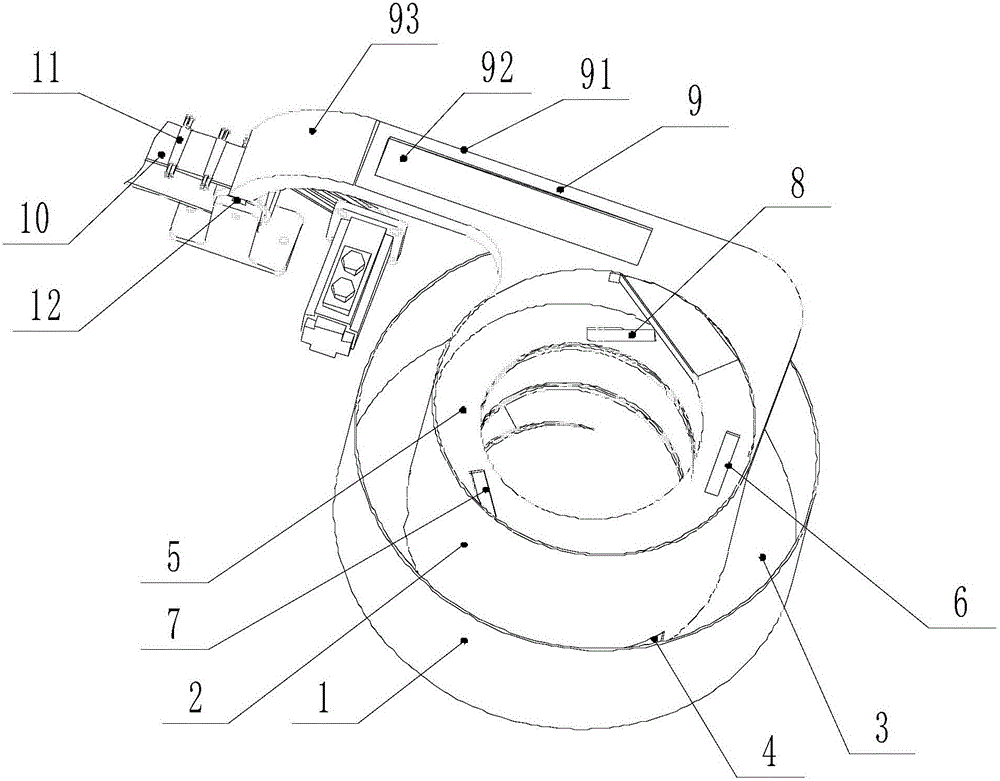

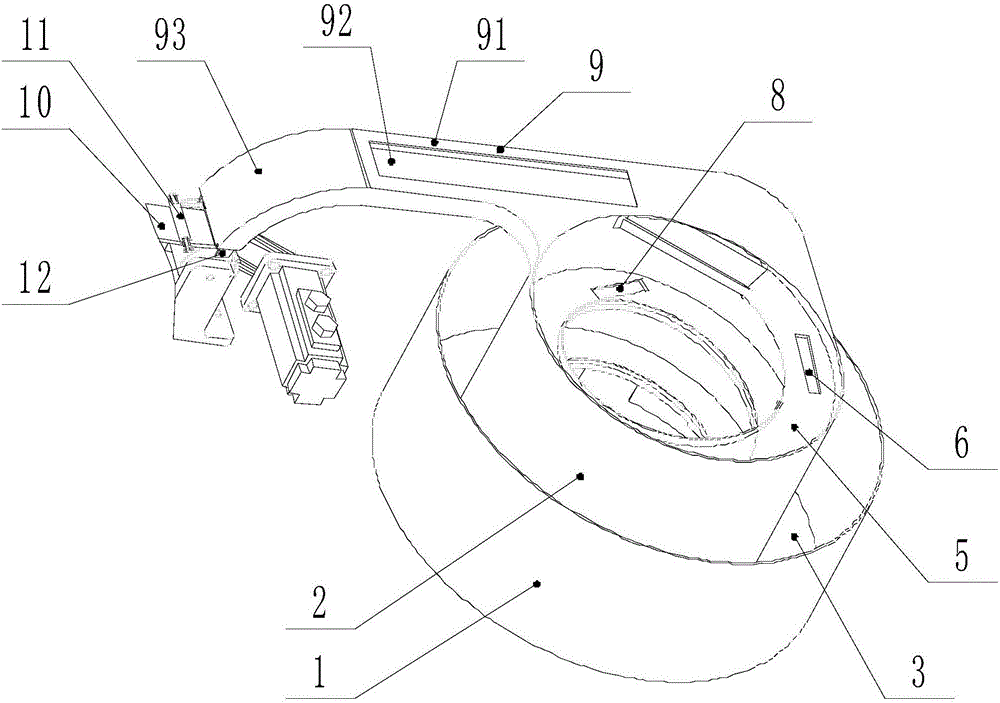

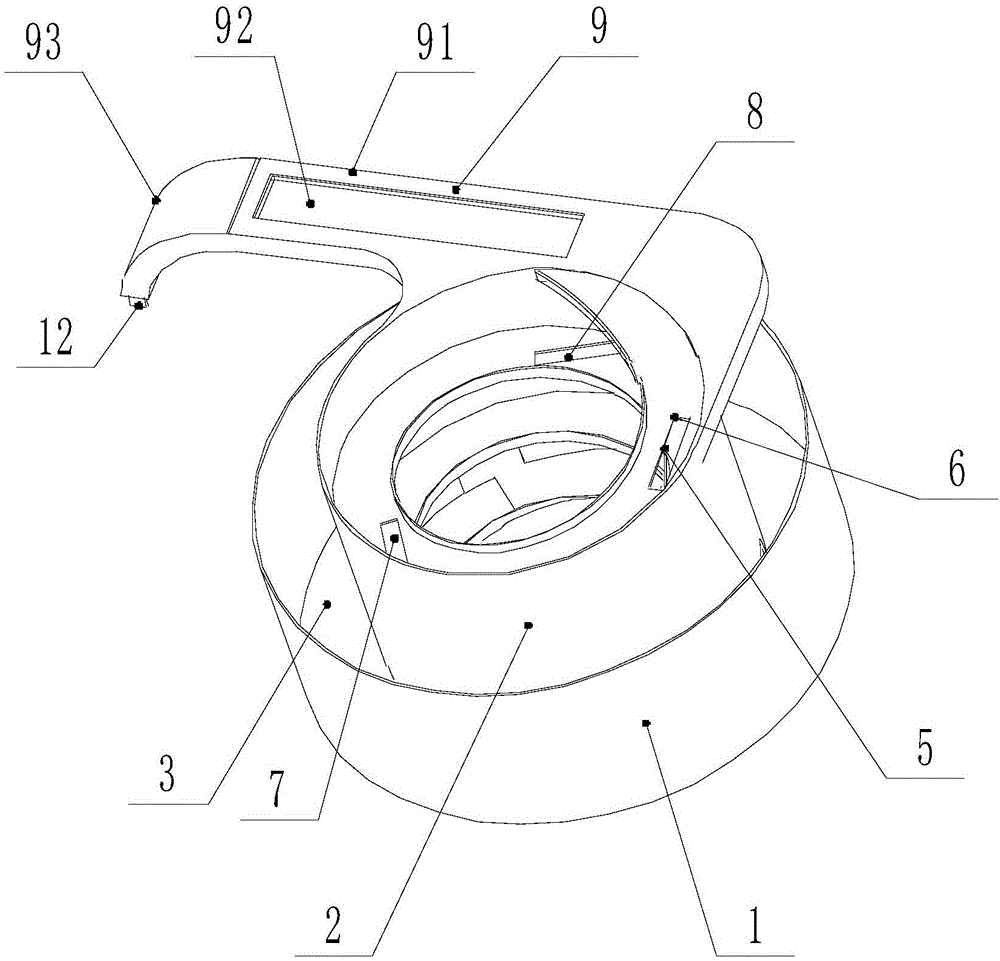

[0024] Such as Figure 1 to Figure 4 As shown, an automatic feeding device for an automatic capping machine for electronic connectors 11 includes a vibrating plate and a connecting channel 9 for connectors. The vibrating plate includes an outer disc body 1 and an inner disc body 2 arranged concentrically. The outer disc body 1 A material storage space 3 is formed between the inner disc body 2, and the bottom of the inner disc body 2 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com