Pushing mechanism in feeding device

A technology of a feeding device and a pushing mechanism, which is applied in the field of feeding devices and pushing mechanisms, can solve the problems that the feeding cannot be smoothly pushed, the workpiece is easy to move, etc., and achieves good positioning effect, smooth and accurate feeding, and easy control. The effect of reciprocating motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

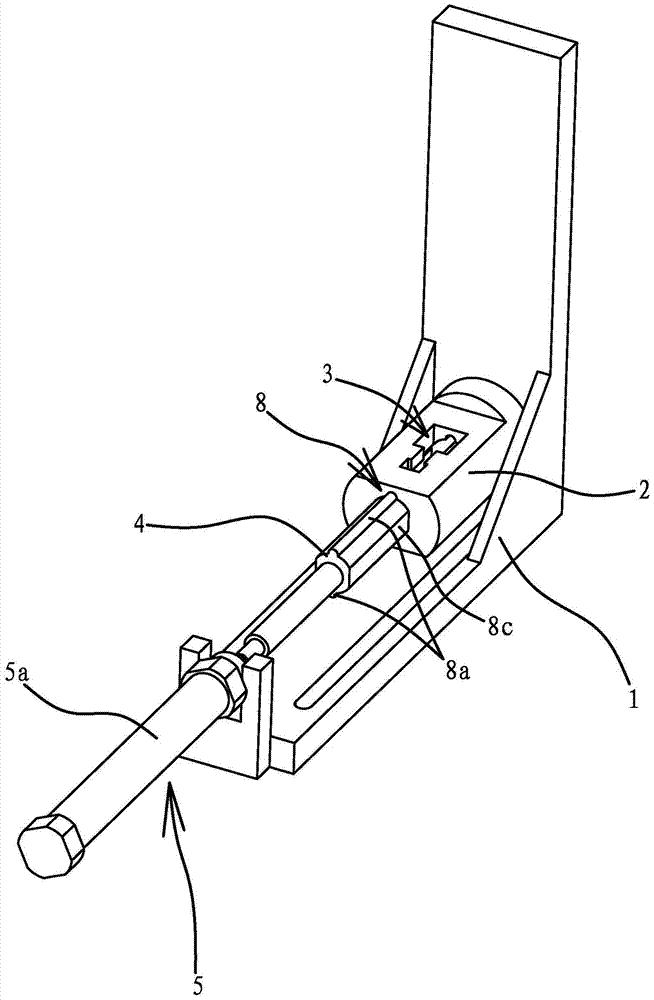

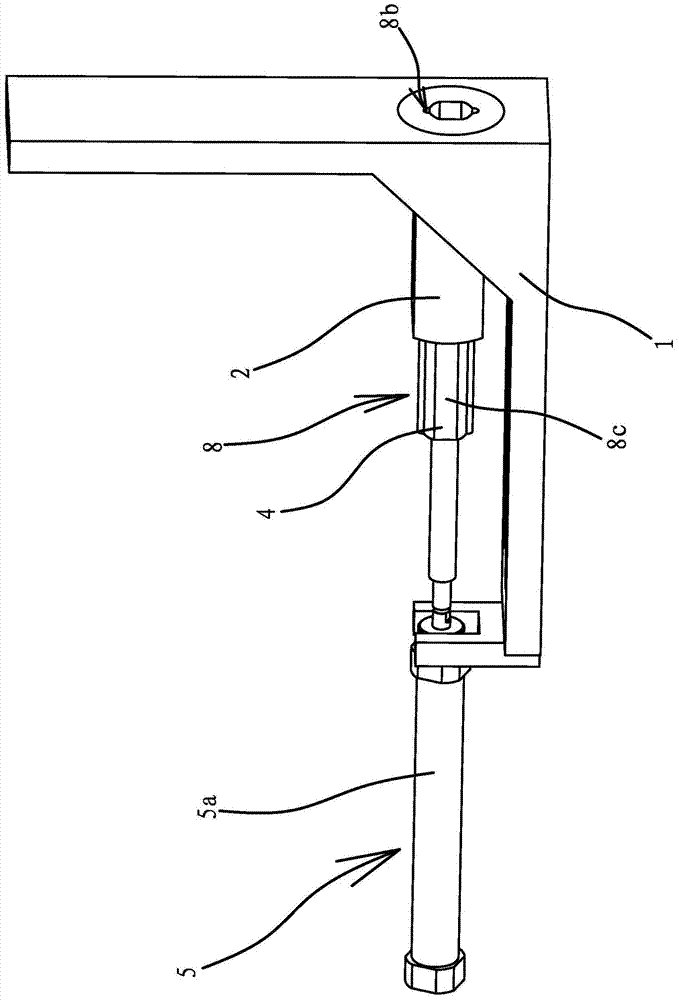

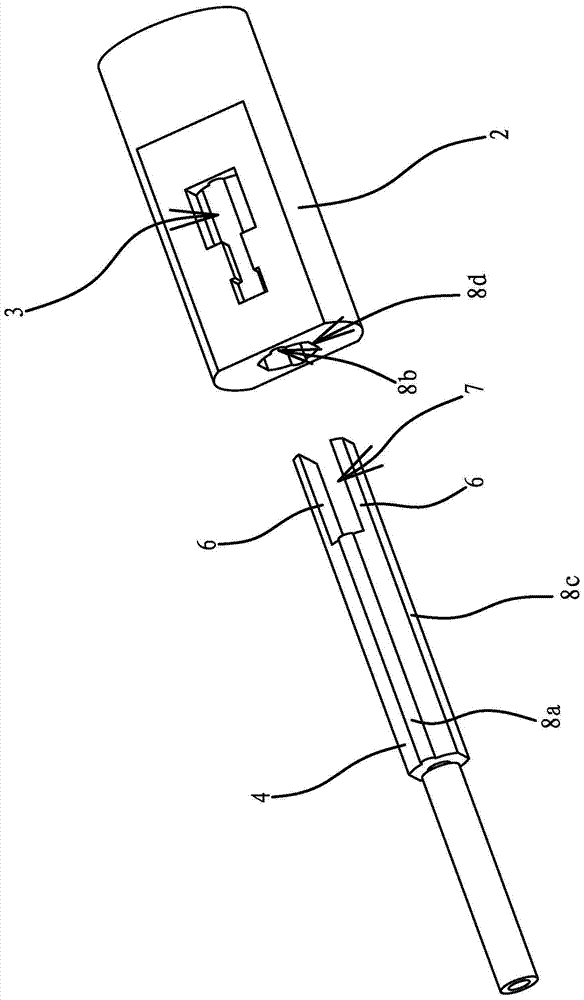

[0035] Such as Figure 1 to 4 7. As shown in 7, the pushing mechanism in the feeding device includes a bracket 1 and a feeding barrel 2 arranged on the bracket 1. One side of the feeding barrel 2 is provided with a feeding port 3, a feeding port 3 and a feeding barrel 2. The cavities are connected, the feeding barrel 2 is provided with a push rod 4, and the support 1 is also provided with a drive mechanism 5 that can drive the push rod 4 to reciprocate. The drive mechanism 5 is a cylinder fixedly connected to the support 1. The piston rod of the cylinder 5a is fixedly connected with the push rod 4.

[0036] The inner end surface of the push rod 4 has a cylindrical pusher 6 protruding from its end surface. The number of the pusher 6 is two, and there is a gap 7 between the two pushers 6, and the cylinder 5a can Drive the push rod 4 to translate so that the clearance gap 7 can be directly opposite to the feed opening 3 of the feeding barrel 2. The pushing part 6 and the pushing r...

Embodiment 2

[0045] The structure and principle of this embodiment are basically the same as those of the first embodiment, and the difference lies in: Figure 5 with 6 As shown, a strip-shaped guide 11 is fixedly connected to the upper side of the feeding barrel 2, and the guide 11 is arranged perpendicular to the axis of the feeding barrel 2. The upper side of the guide 11 has a guide groove 11a, which is arranged along the axial direction of the guide 11, and the bottom of the guide groove 11a is provided with a through feeding port 11b. The feeding port 11b is connected to the feeding barrel 2. The structure and position of the feed port 1-3 correspond one by one. A blanking plate 9 is embedded in the guide groove 11a, and a driving mechanism 10 that can drive the blanking plate 9 to reciprocate is positioned on the feeding barrel 2. The blanking plate 9 is provided with two feeding ports 9a and two feeding ports 9a. Vertically penetrating through the blanking plate 9, the second drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com