Pusher components in the feeder

A feeding device and component technology, which is applied in metal processing and other directions, can solve the problems of easy falling of workpieces and processing omissions, etc., and achieve good positioning effect, smooth and accurate feeding, and good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

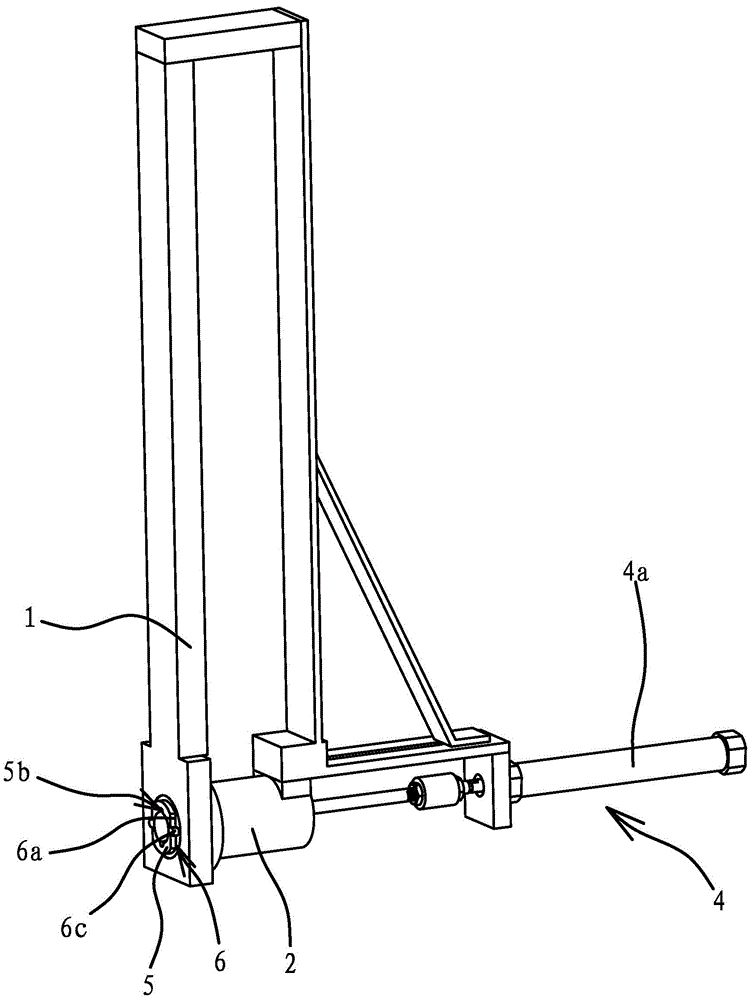

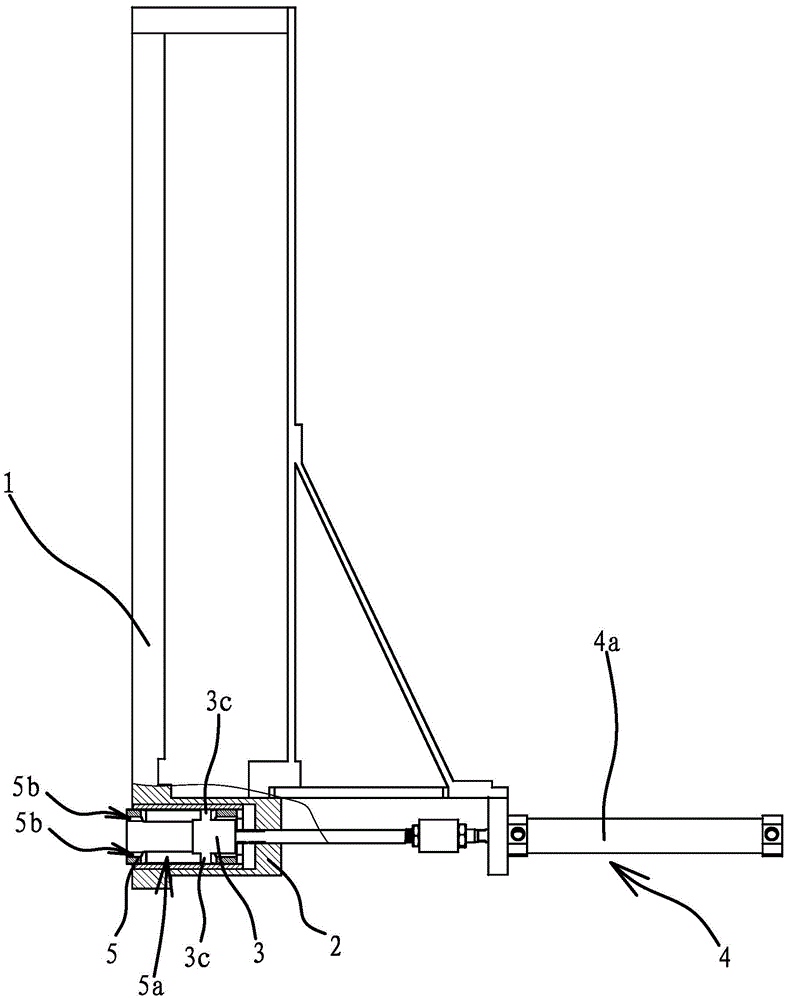

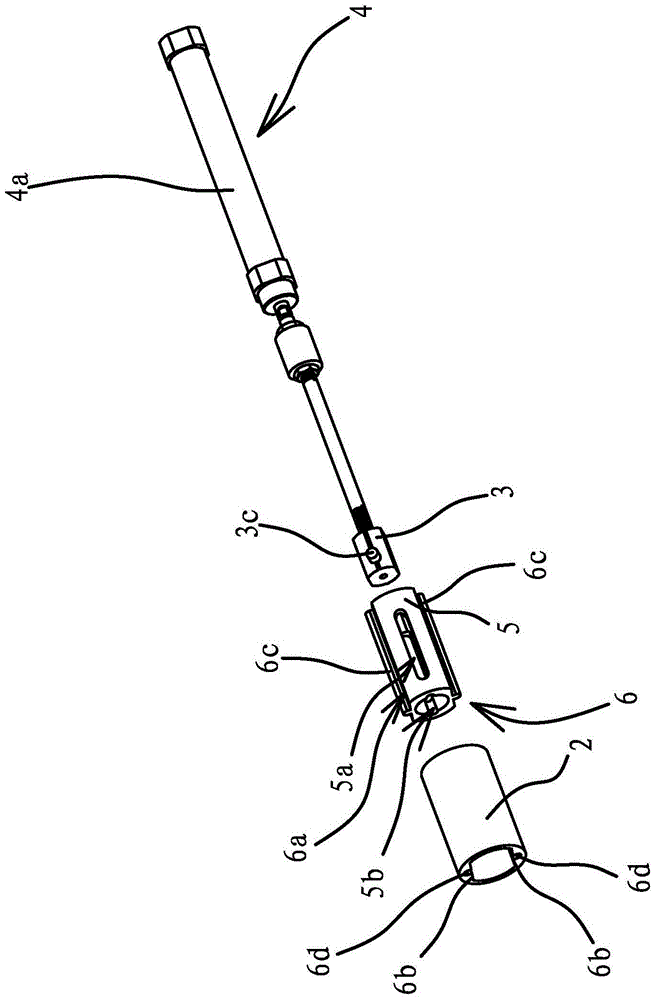

[0030] like Figures 1 to 3 As shown, the pusher assembly in the feeding device includes a bracket 1 and a feeding cylinder 2 arranged on the bracket 1. The bracket 1 is in the shape of a frame, which has the advantages of firm structure and convenient manufacture. The feeding cylinder 2 is installed on the underside of the support 1 . The feeding cylinder 2 is provided with a push rod 3, and the bracket 1 is also provided with a drive mechanism 4, and the drive mechanism 4 drives the push rod 3 to reciprocate in translation, and the drive mechanism 4 includes a cylinder body fixedly connected to the bracket 1 The cylinder 4a, the piston rod of the cylinder 4a is fixedly connected with one end of the push rod 3. The driving mechanism 4 adopts the air cylinder 4a, which has the advantages of simple structure and high efficiency of pushing materials. As another way, the driving mechanism 4 includes a motor whose casing is fixedly connected to the bracket 1, a gear is fixedly c...

Embodiment 2

[0037] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 4 As shown, the inner end surface of the pusher rod 3 has a columnar pusher portion 3a protruding from the end face, the number of pusher portions 3a is two, and there is a gap 3b between the two pusher portions 3a.

[0038] When feeding a special-shaped workpiece, one end of the workpiece is columnar or cylindrical, and the other end has a convex body protruding from the end surface. When the ordinary feeding mechanism is pushing, the workpiece is easy to swing, and accurate and stable feeding cannot be realized. When using this pushing assembly for pushing, the two pushing parts 3a are all against the end face of the workpiece, the convex body of the workpiece is located in the gap 3b, and the workpiece is pushed out along the axis of the feeding cylinder 2, so that the The pushing mechanism in the workpiece feeding device can feed the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com