Extensible guiding hook arrangement device

A yarn guide hook and installation position technology, applied in textiles and papermaking, etc., can solve the problem of not being able to achieve the best yarn performance, and achieve the effect of optimizing the yarn forming performance and improving the yarn forming performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Accompanying drawing non-restrictively discloses the structural representation of preferred embodiment involved in the present invention; Below in conjunction with accompanying drawing

[0020] The technical solution of the present invention is described in detail.

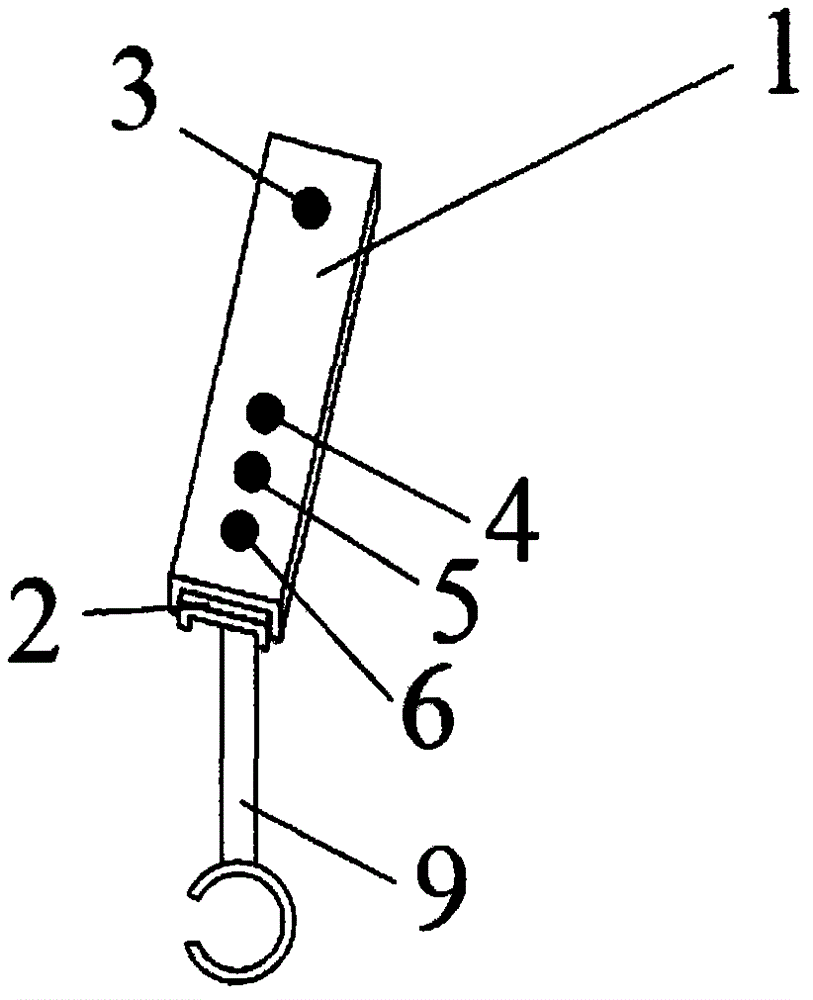

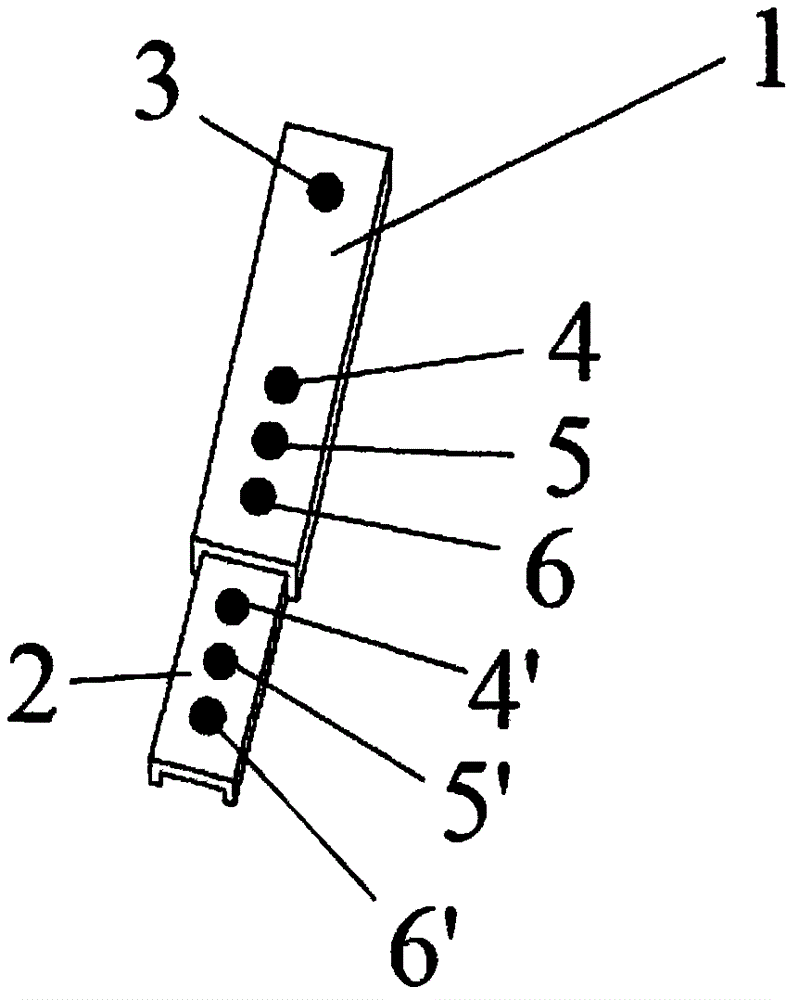

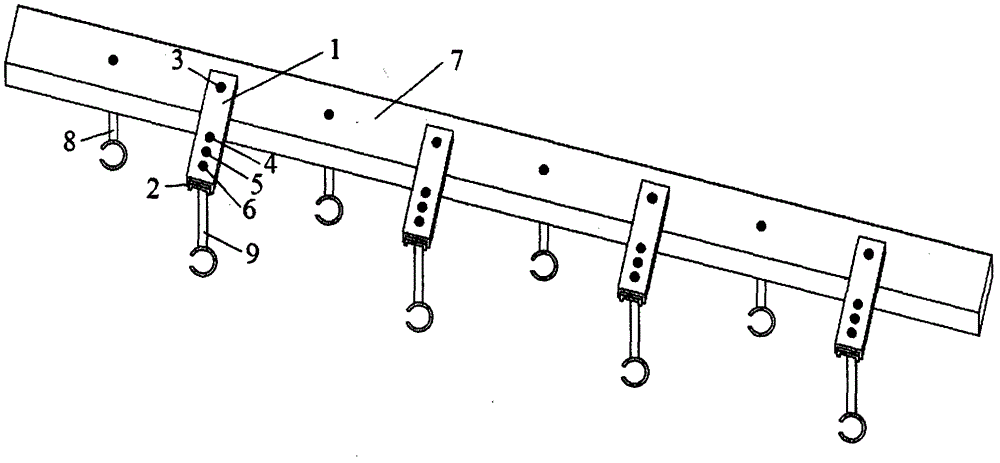

[0021] like figure 1 , figure 2 , image 3 As shown, the retractable yarn guide hook placement device of the present invention includes a placement support 1, a placement support 2, a mounting hole 3, a yarn guide hook 8, a yarn guide hook 9 and screws.

[0022] in:

[0023] The described support 1 and support 2 are in fact rods, and the support 2 is placed in the groove of the support 1 and can be stretched. When spinning with a smaller phase, use holes 4, 5, and 6 on the placement support 1 to install the guide hooks. When a larger phase is required, pull out the placement support 2 and install the guide hooks. Spinning is carried out on hole positions 4', 5', 6'. There are three positions on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com