A kind of comfortable hemp-like knitted fabric and its preparation process

A preparation process, linen knitting technology, applied in the field of knitted fabrics, can solve the problems of sweating not close to the body, poor spinning cohesion, poor wear resistance, etc., and achieve the effect of easy dyeing, excellent texture and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

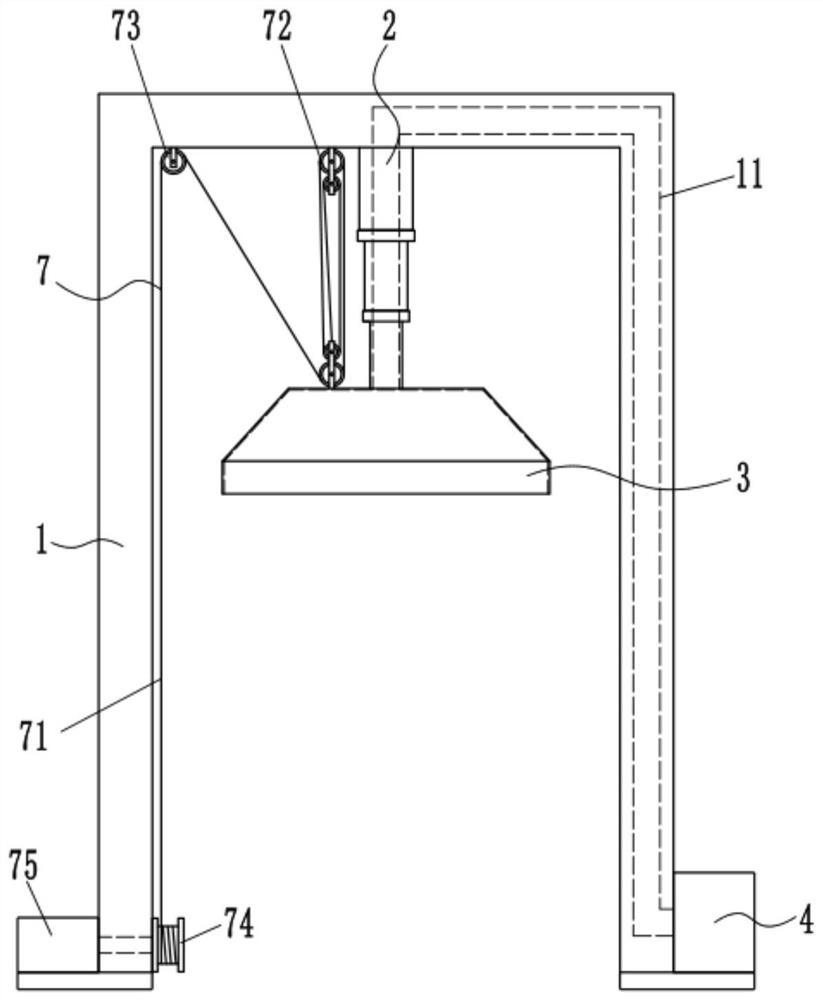

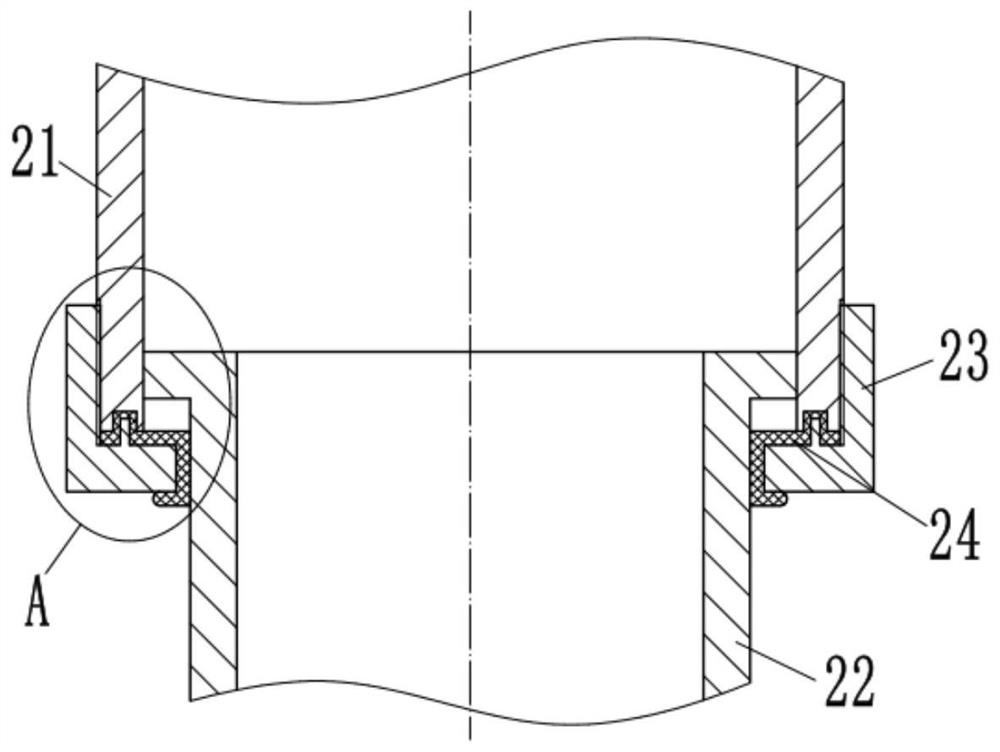

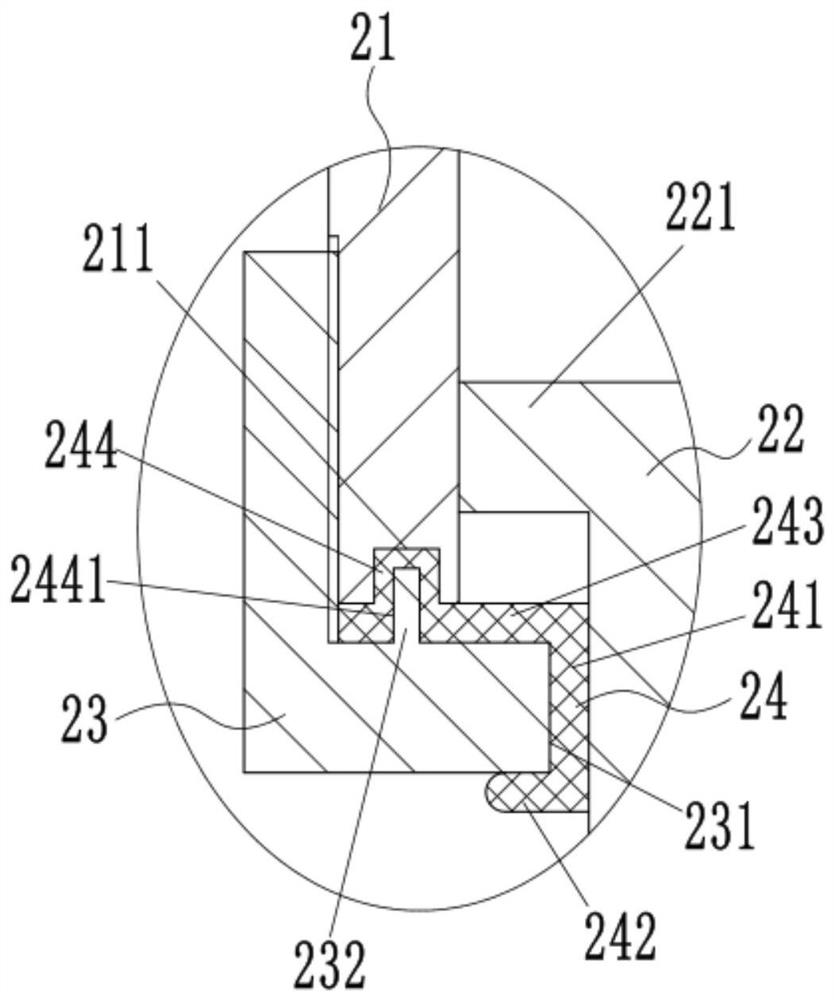

Image

Examples

Embodiment 1

[0042] A comfortable linen-like knitted fabric

[0043] Comfortable linen-like knitted fabric is made of blended acrylic staple, viscose fiber, cotton fiber and slub cotton; in comfortable linen-like knitted fabric, by mass percentage, acrylic staple is 15% and viscose is 35% , Slub cotton is 10%, and the balance is cotton fiber.

[0044] Include the following steps:

[0045] Step 1, surface modification of viscose fiber: prepare 1.0mol / L methyl methacrylate solution, adjust the pH to 6.0, then add the viscose soaked in 0.05mol / L potassium permanganate solution for 10min in advance The fiber is kept in a water bath at a temperature of 65°C for 120 minutes, and then the homopolymer is removed with a mixture of ethanol and water with a volume ratio of 4:1, and then dehydrated by centrifugation. After the product is air-dried, it is dried, which is surface modification. viscose, spare;

[0046] Step II, spinning: the surface modified viscose fiber obtained in step I is blended...

Embodiment 2

[0057] A comfortable linen-like knitted fabric

[0058] Comfortable linen-like knitted fabric is made of blended acrylic staple, viscose fiber, cotton fiber and slub cotton; in comfortable linen-like knitted fabric, by mass percentage, acrylic staple is 25% and viscose is 25% , slub cotton is 20%, and the balance is cotton fiber.

[0059] Include the following steps:

[0060] Step 1, viscose fiber surface modification: prepare the methyl methacrylate solution of 1.0mol / L, adjust pH to be 6.3, then add the described viscose soaked in the potassium permanganate solution of 0.1mol / L in advance for 15min The fiber is kept in a water bath at a temperature of 75°C for 150 minutes, and then the homopolymer is removed with a mixture of ethanol and water with a volume ratio of 4.5:1, and then dehydrated by centrifugation. After the product is air-dried, it is dried, which is the surface modification. viscose, spare;

[0061] Step II, spinning: the surface modified viscose fiber obta...

Embodiment 3

[0066] A comfortable linen-like knitted fabric

[0067] Comfortable linen-like knitted fabric is made of blended acrylic staple, viscose fiber, cotton fiber and slub cotton; in comfortable linen-like knitted fabric, by mass percentage, acrylic staple is 18% and viscose is 32% , Slub cotton is 12%, and the balance is cotton fiber.

[0068] Include the following steps:

[0069] Step 1, surface modification of viscose fiber: prepare 1.0mol / L methyl methacrylate solution, adjust the pH to 6.1, then add the viscose soaked in 0.06mol / L potassium permanganate solution for 11min in advance The fiber is kept in a water bath at a temperature of 68°C for 130 minutes, and then the homopolymer is removed with a mixture of ethanol and water with a volume ratio of 4.1:1, and then dehydrated by centrifugation. The product is air-dried and then dried, which is surface modification. viscose, spare;

[0070] Step II, spinning: the surface modified viscose fiber obtained in step I is blended w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com