Roof collapse treatment method for detecting inbreak area through drilling peeping instrument

A technology of caving area and peeping instrument, applied in the field of roof collapse control, can solve the problems of large secondary caving, complicated process, perishable deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

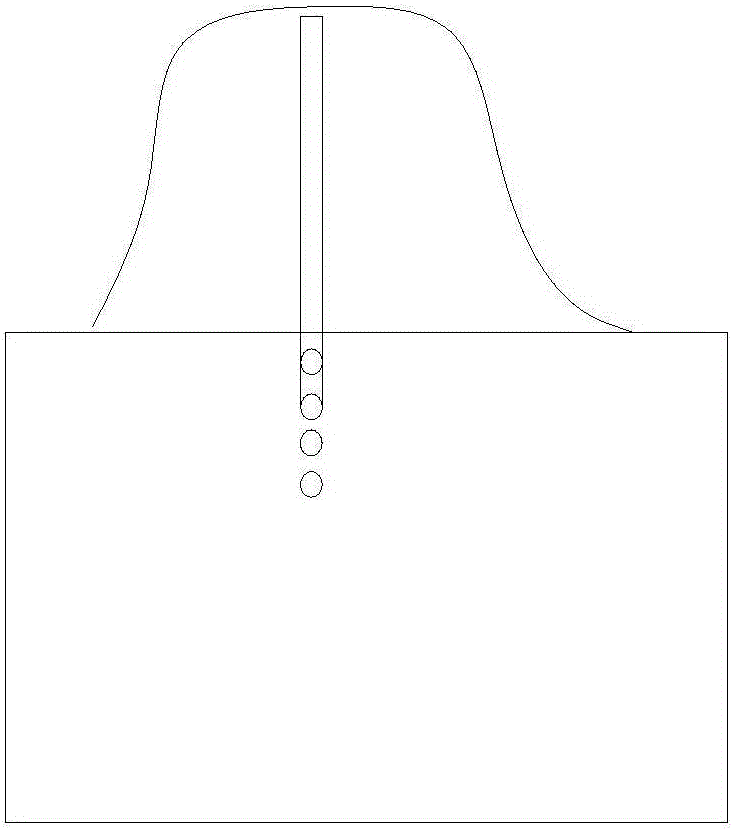

[0060] A roof subsidence control method using a borehole peeping instrument to detect a caving area, comprising the following steps:

[0061] (1) Judgment of the severity of the roof fall: judge whether the gangue completely blocks the roadway according to the amount of gangue falling; when the gangue completely blocks the roadway, judge the stability of the surrounding rock by evaluating the stability of the surrounding rock. Stable, unstable surrounding rock, general stability of surrounding rock, relatively stable surrounding rock and extremely stable surrounding rock;

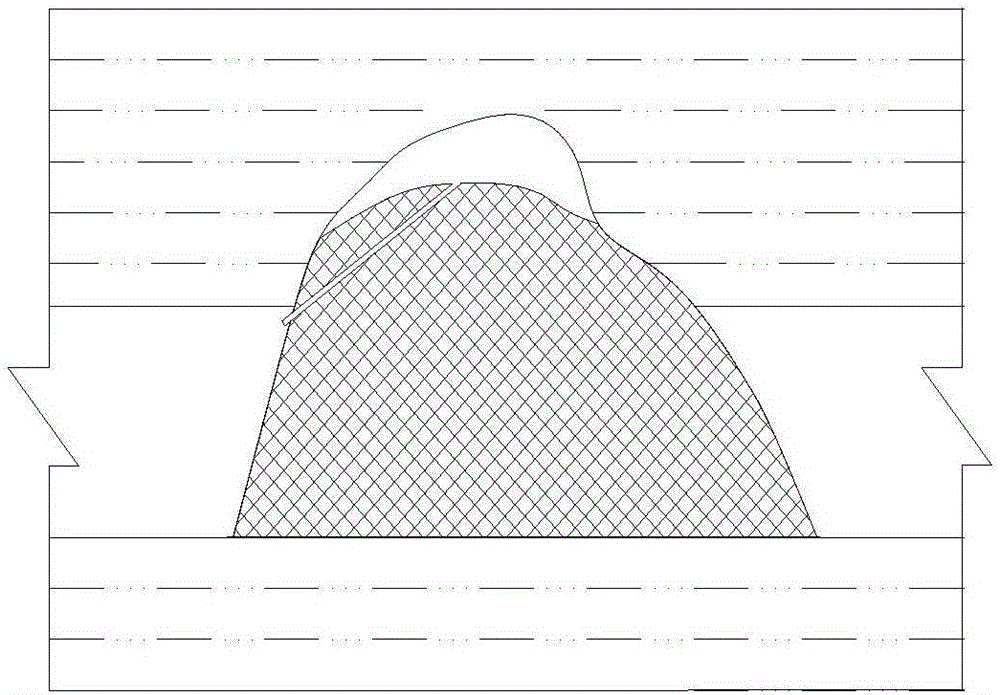

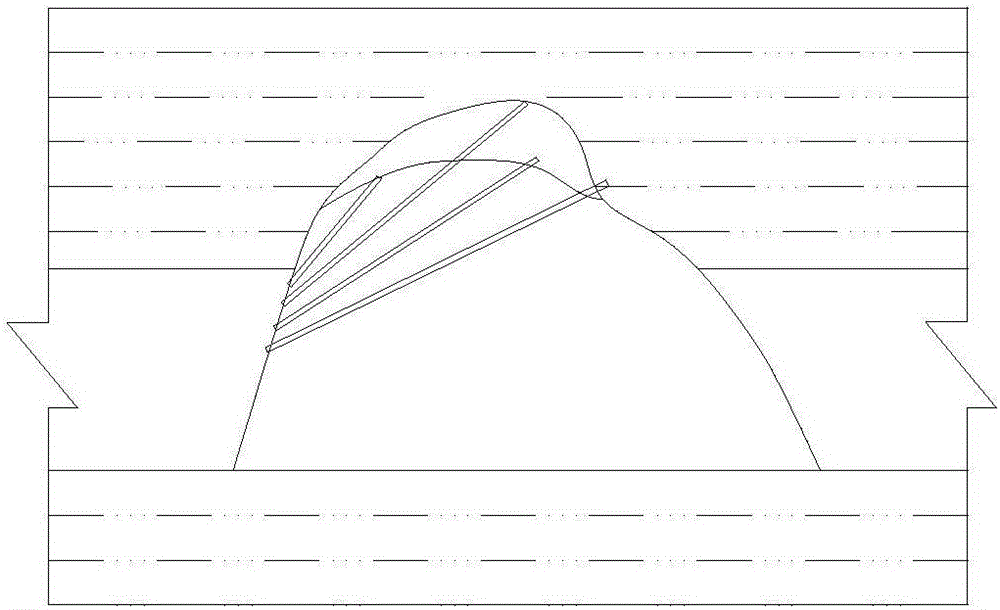

[0062] (2) Drilling holes are drilled in the gangue pile falling from the middle and upper part of the roadway section, and the length direction of the drilling holes is at an angle of α with the plane where the roadway bottom plate is located, such as figure 1 As shown, the range of α angle is:

[0063] The angle is 63° under extremely unstable surrounding rock conditions, 49° under unstable surrounding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com