Test joint

A technology of three-way joints and variable buckle joints, which is applied in the direction of measuring the increase and deceleration rate of the fluid, using liquid/vacuum to measure the liquid tightness, etc., can solve the problems of wasting time, pressure leakage, safety hazards, etc., and achieve structural The design is simple and reasonable, reducing safety hazards and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

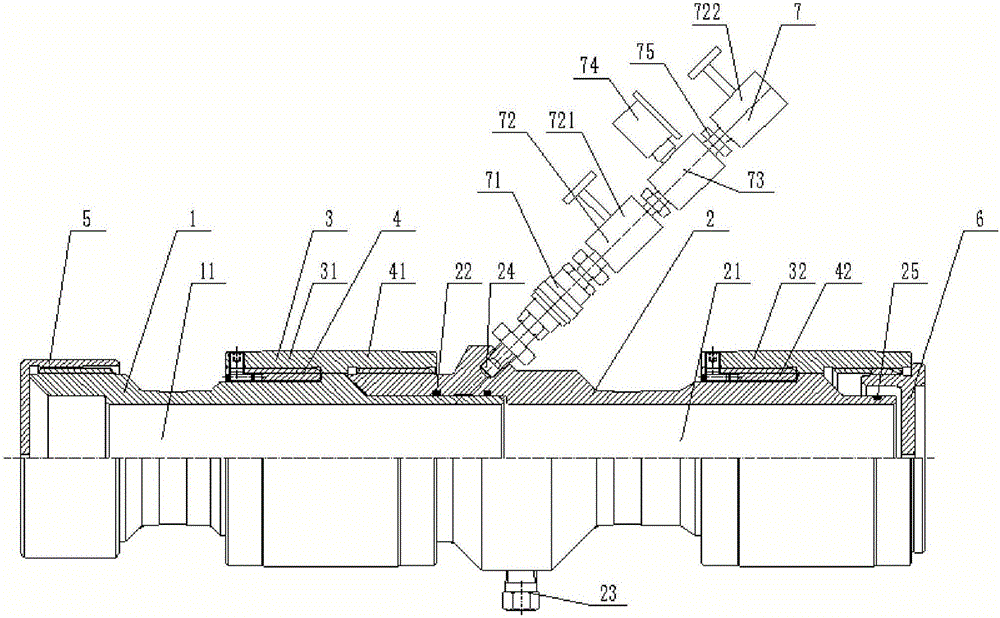

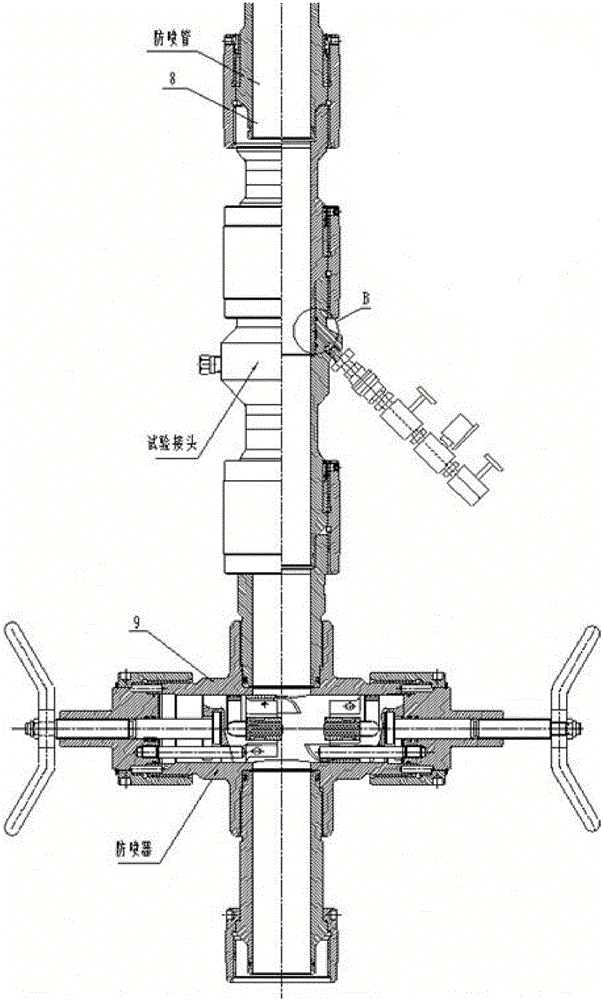

[0019] Such as figure 1 As shown, the test joint of the present invention has a shaft structure as a whole and includes an upper joint 1, a lower joint 2, a union cover 3, slips 4, an upper wire protection cover 5, a lower wire protection cover 6 and a test instrument string 7.

[0020] The inside of the upper joint 1 is provided with an upper joint through hole 11 along the axial direction. The silk caps 5 are connected by threads.

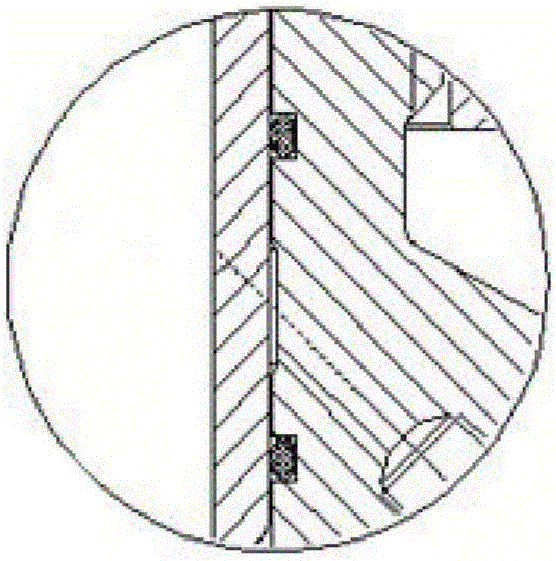

[0021] A lower joint through hole 21 is axially penetrated inside the lower joint 2 , and the center of the lower joint through hole 21 is coaxial with the upper joint through hole 11 of the upper joint 1 . Wherein, the upper end of the lower joint 2 is matched and socketed outside the lower end of the upper joint 1, and the inner wall of the upper end of the lower joint 2 is also provided with a pair of lower joint sealing grooves, and a pair of first O-shaped sealing grooves are installed in the pair of lower joint sealing grooves. Sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com