A skeletonless optical fiber current sensing loop and its manufacturing method

A technology of sensing loops and optical fiber loops, applied in the direction of voltage/current isolation, fiber mechanical structure, etc., can solve the problem of affecting the measurement accuracy of optical fiber current transformers, the skeleton is easily affected by external temperature changes, and the sensing loop produces effects and other problems, to achieve the effect of high reliability, simple production and reasonable scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A skeletonless optical fiber current sensing loop and its manufacturing method of the present invention will be described in detail below with reference to the drawings and embodiments.

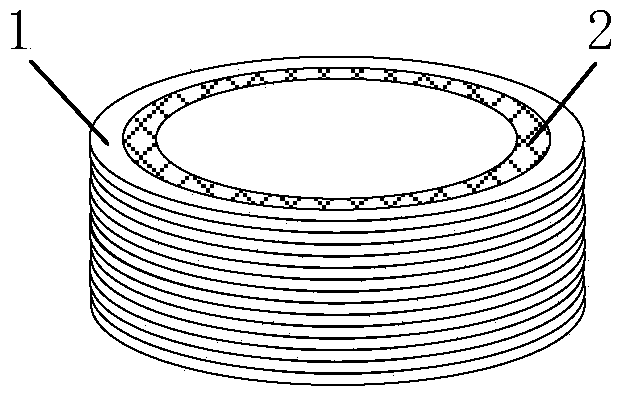

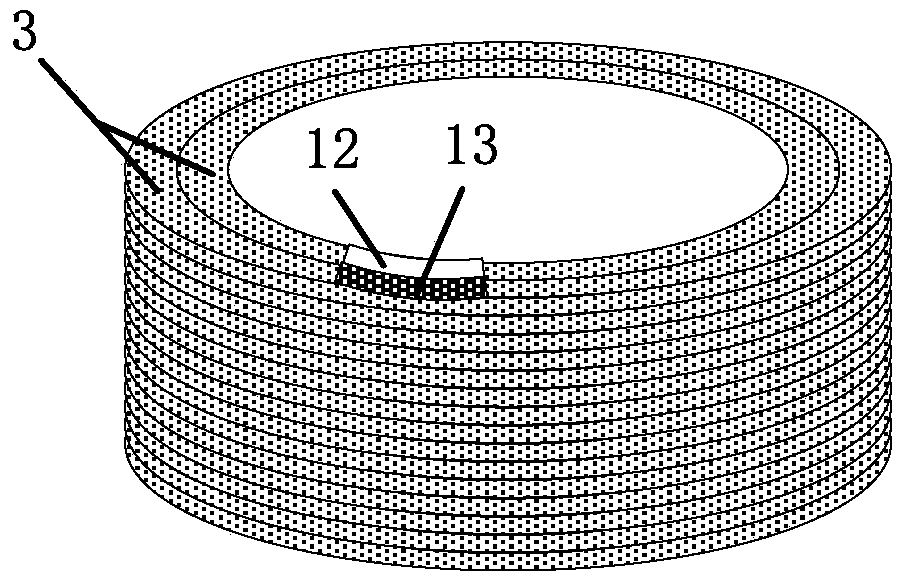

[0032] The shape of the skeletonless optical fiber current sensing loop of the present invention is as follows figure 2 As shown, it includes an optical cable 3, a mirror 12 and a 1 / 4 wave plate 13. The optical cable 3 is firstly circled from top to bottom, and then from bottom to top to form two circles inside and outside, and two adjacent optical cables 3 are closely arranged and bonded with ultraviolet curing glue 9; the starting end of the optical cable 3 Set side by side with the end end, the start end is connected with the reflector 12, and the end end is connected with the 1 / 4 wave plate 13,

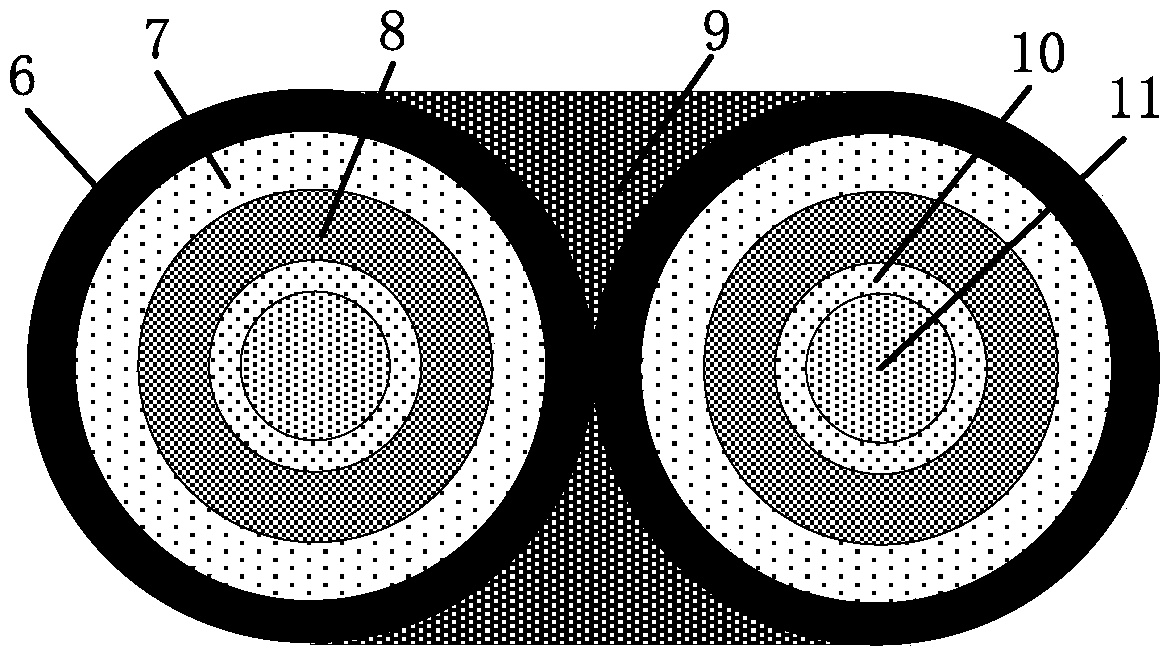

[0033] Such as image 3 As shown, the optical cable 3 is composed of: polyethylene sheath 6, aramid yarn 7, loose tube 8, casing filling oil 10 and bare spun optical fiber 11, the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com