An electrowetting device

An electrowetting and device technology, applied in the field of electrowetting, can solve the problem of reducing the light transmittance of the device, and achieve the effect of improving the light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

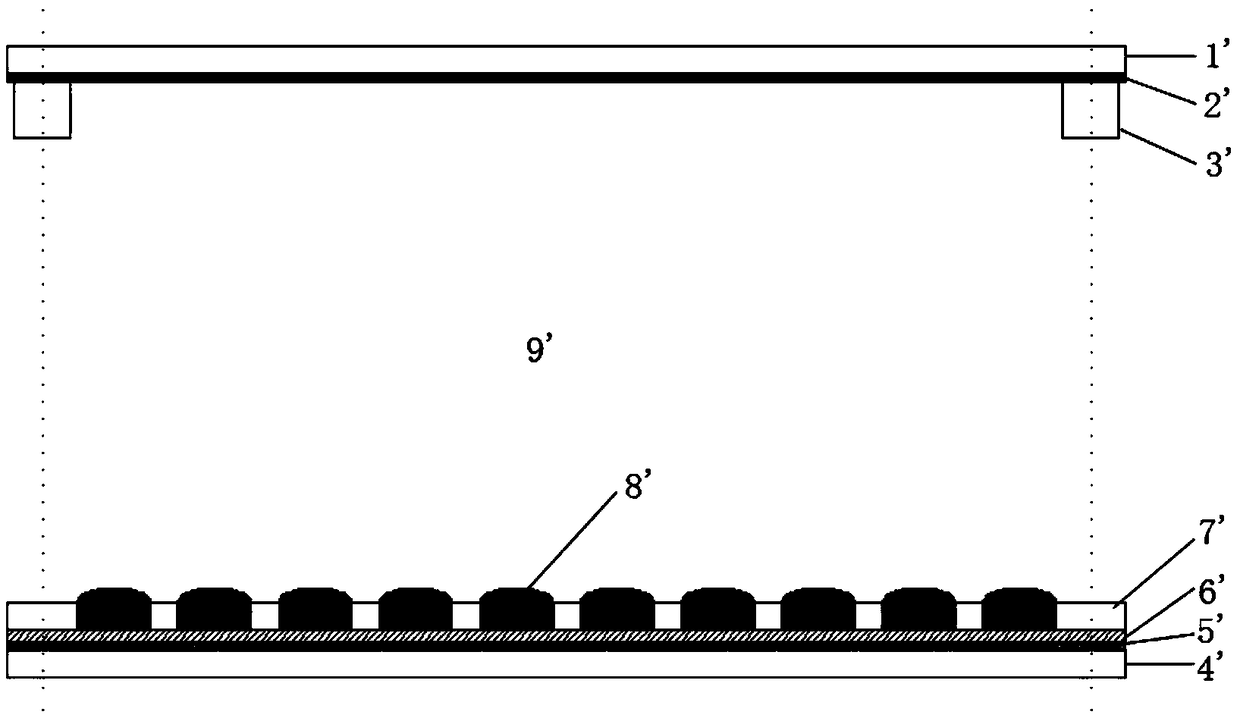

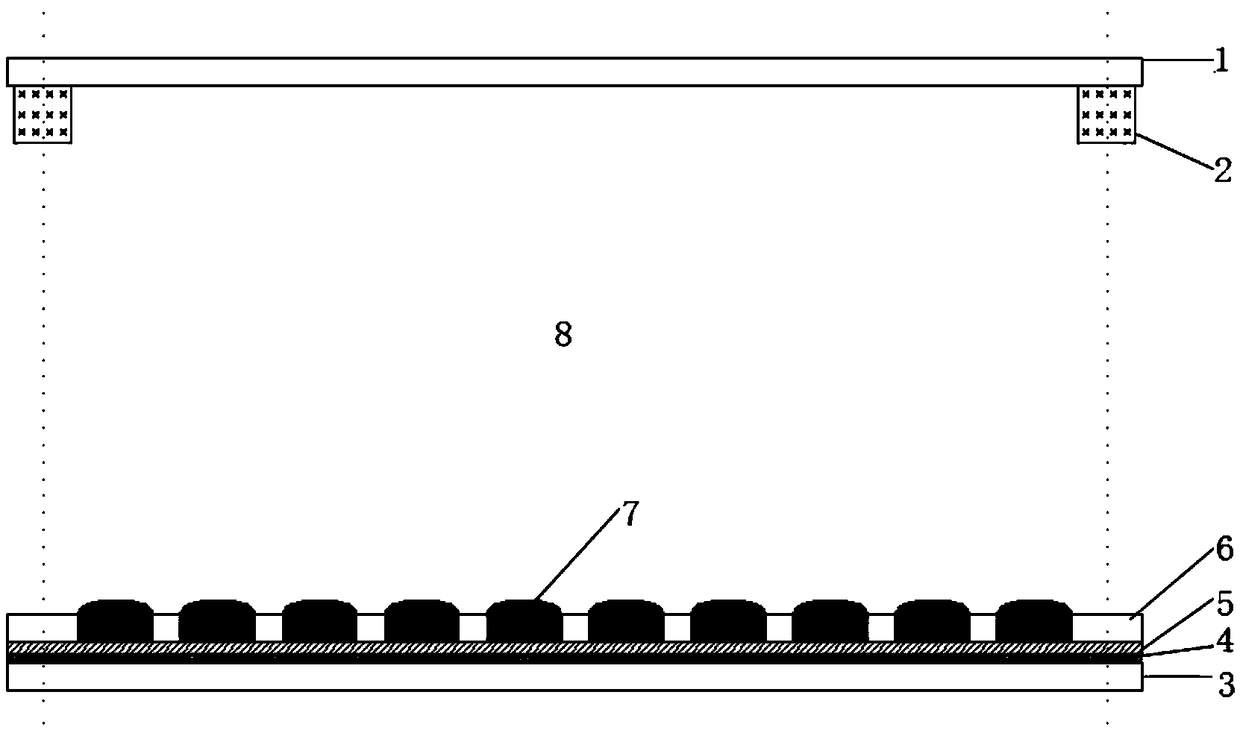

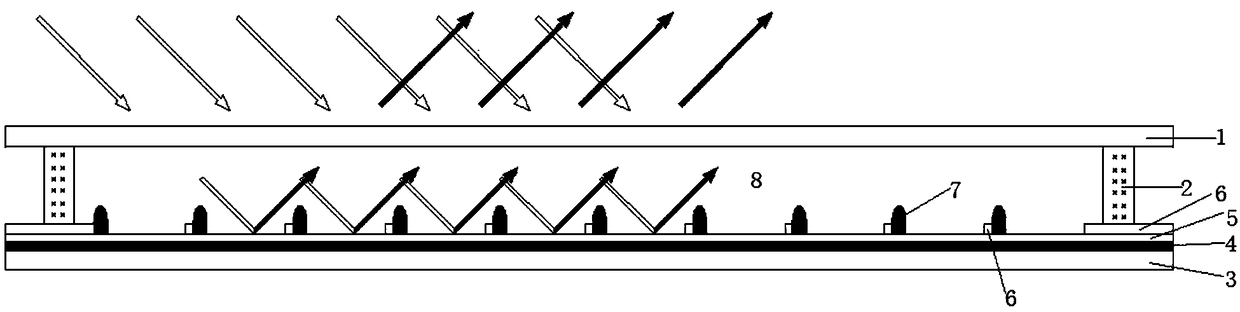

[0025] refer to figure 2 , figure 2 It is a cross-sectional structure diagram of the electrowetting device of Example 1. The present invention provides an electrowetting device, including an upper substrate, a lower substrate and a packaging plastic frame, the upper substrate includes an upper light-transmitting substrate 1, and the upper substrate The light-transmitting substrate 1 is AR coated anti-reflection glass. The lower substrate includes a lower light-transmitting substrate 3, a conductive layer 4, a hydrophobic insulating layer 5, and a pixel wall 6 arranged in sequence. The upper light-transmitting substrate 1 and the lower substrate pass through the encapsulation plastic frame 2 sealed and closed, the formed cavity is filled with electrolyte solution 8, each pixel grid surrounded by the pixel wall 6 is filled with ink 7, the packaging plastic frame 2 is a conductive packaging plastic frame, and the conductive packaging plastic frame 2 It can replace the function...

Embodiment 2

[0028] refer to Figure 4 , Figure 4 It is a cross-sectional structure diagram of the conductive packaging plastic frame of embodiment 2. This embodiment is basically the same as that of embodiment 1, except that the conductive packaging plastic frame 2 includes a plastic frame 9 and a conductive metal layer 10, and the conductive metal Layer 10 is in communication with the electrolyte solution. In this embodiment, the conductive metal layer 10 is attached to the inner wall of the plastic frame 9 .

Embodiment 3

[0030] refer to Figure 5 , Figure 5 It is a cross-sectional structure diagram of the conductive packaging plastic frame of embodiment 3. This embodiment is basically the same as that of embodiment 2, except that the conductive packaging plastic frame 2 includes a plastic frame 9 and a conductive metal layer 10, and the conductive metal Layer 10 is in communication with the electrolyte solution. In this embodiment, the conductive metal layer runs through the plastic frame 9 laterally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com