Restructuring method of processing box and restructured processing box

A process cartridge and installation direction technology, applied in the field of remanufacturing methods and remanufactured process cartridges, can solve the problem that the process cartridge cannot be taken out smoothly for the driving member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

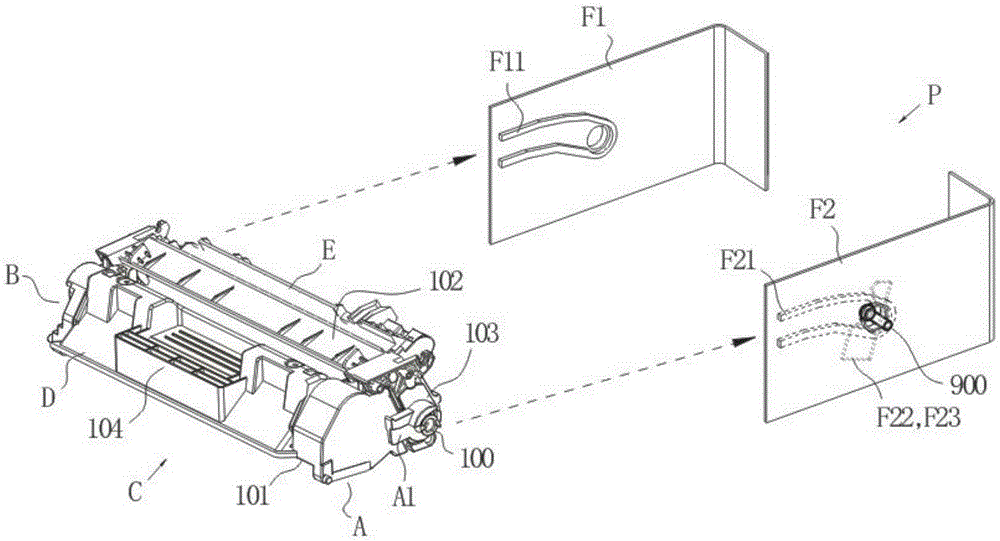

[0038] Please refer to Figure 1-Figure 6 , the present embodiment provides a method for remanufacturing a process cartridge and the remanufactured process cartridge obtained thereby, so that the process cartridge can be easily disassembled from the imaging device.

[0039] (The structure of the treatment box before modification)

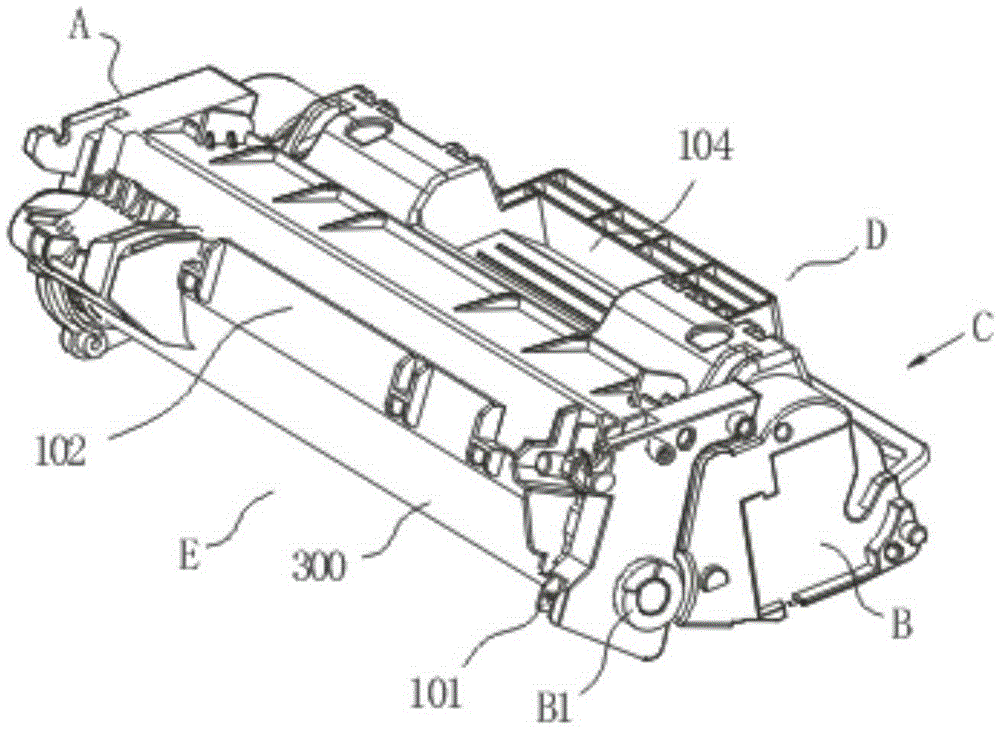

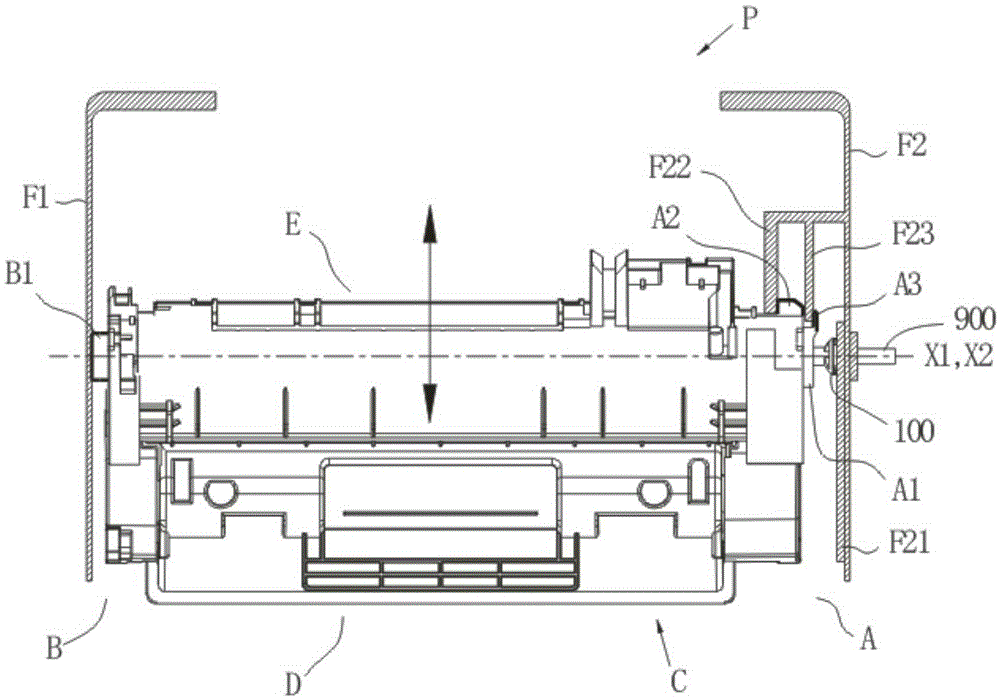

[0040] Such as Figure 1-Figure 3 As shown, the process cartridge C before remanufacturing includes: a housing 101, a driving end A and a conductive end B located on both lateral sides of the housing, and a front end E facing the installation direction and a rear end D facing the pulling direction. The housing 101 includes a waste toner bin 102 and a drum bracket 103. The drum bracket 103 is arranged at the driving end of the waste toner bin 102 for supporting the photosensitive element 300 and the photosensitive element arranged in the waste toner bin. The drive member 100 at the end of the drive end rotates.

[0041] Such as Figure 4 As shown...

Embodiment 2

[0056] Please refer to Figure 5 as well as Figure 8-Figure 10a , the present embodiment provides a method for remanufacturing a process cartridge and the resulting remanufactured process cartridge. On the basis of the structure of the process cartridge in Embodiment 1, a limiter is further added at the driving end A of the process cartridge toward the front end E. The position avoidance part is a telescopic member that can expand and contract relative to the surface of the process cartridge housing where it is located, or an elastic member that can undergo elastic deformation such as a rubber stopper. After the process box is installed in the image forming device, the position avoidance part can be inserted into the gap between the first limiting rib F22 and the second limiting rib F23, or can be inserted into the second limiting rib F23 and the second limiting rib F23. In the gap between the right side wall F2, to prevent the process box from vibrating and shifting during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com