Machine tool

A technology of machine tools and motors, applied in the field of machine tools, can solve the problems of decreased productivity, complex operations, time required for testing, etc., and achieve the effect of preventing unwanted movement and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

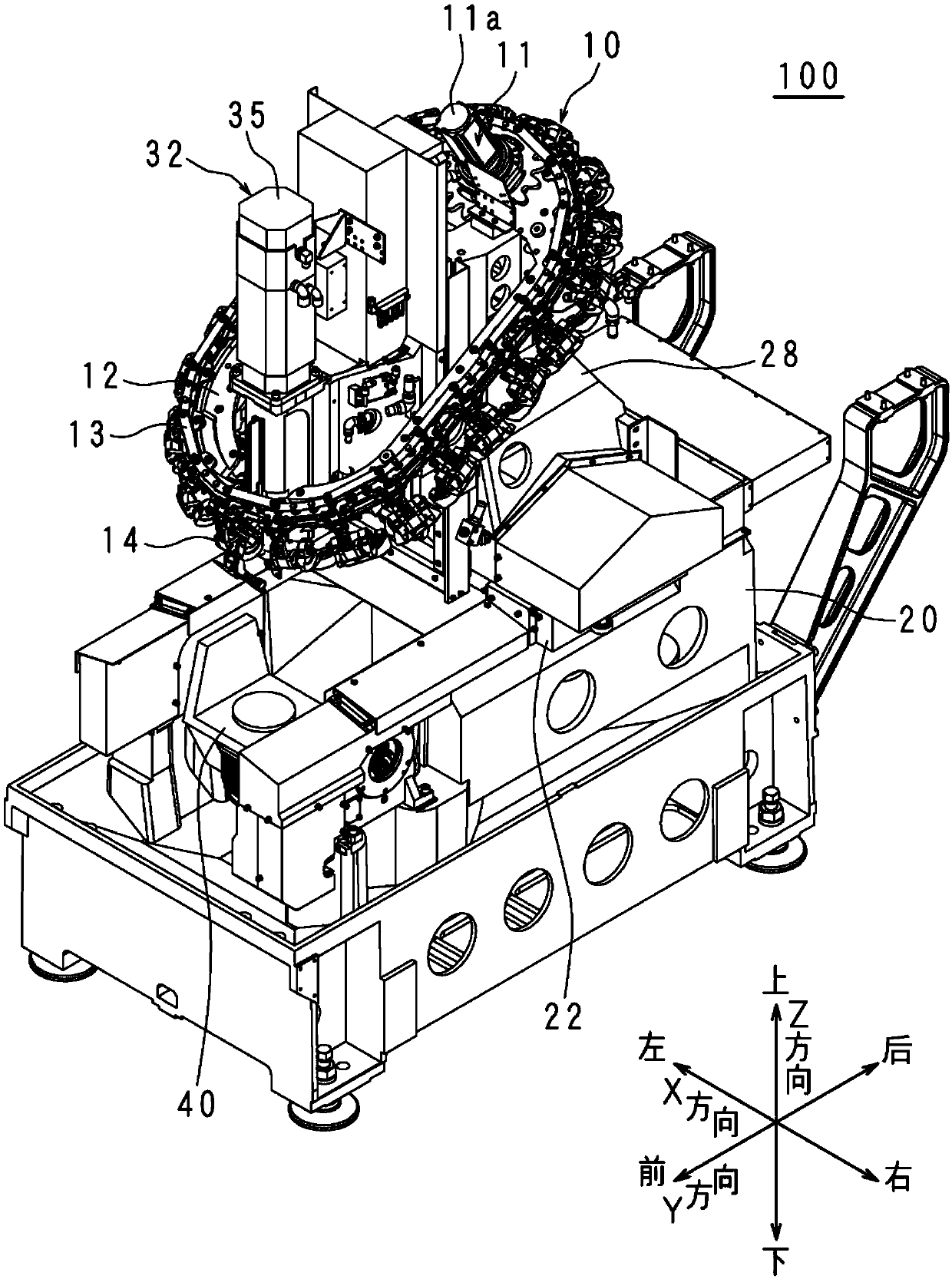

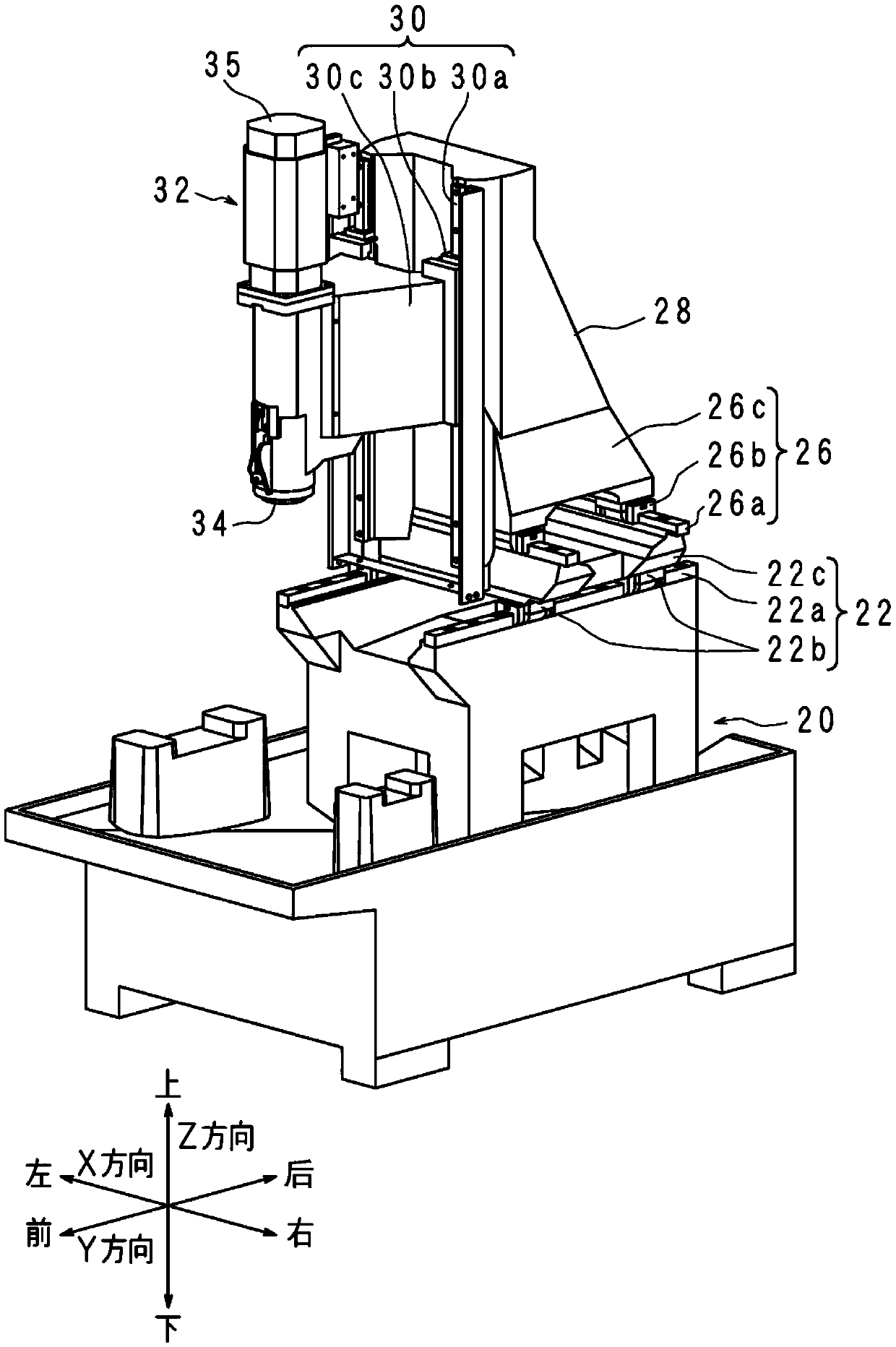

[0024] Hereinafter, the present invention will be described in detail based on drawings showing machine tools of the embodiments. In the following description, up and down, left and right, and front and rear indicated by arrows in the drawings are used.

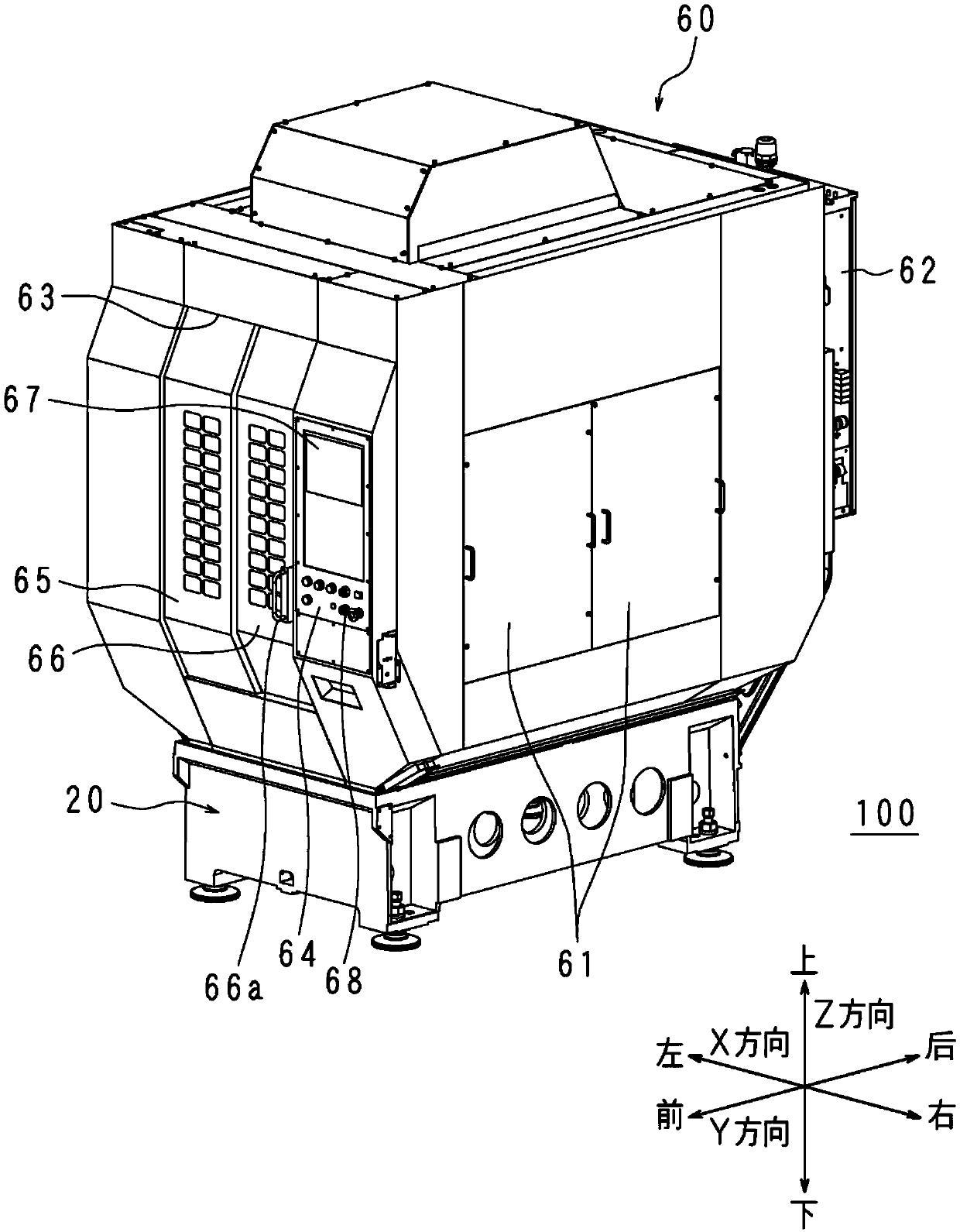

[0025] Such as figure 1 As shown, the machine tool cover 60 is provided on the upper side of the base 20 of the machine tool 100 . The machine tool cover 60 has a rectangular box shape. The machine tool cover 60 has two detachable plates 61 at the center of both left and right sides. The operator removes the plate 61 as necessary to perform maintenance and management of the machine tool. The control panel 62 is provided on the back of the machine tool cover 60 and has a control unit 90 for controlling the operation of the machine tool and an amplifier for supplying electric power to each motor.

[0026] A vertically elongated rectangular opening 63 is provided at the front central portion of the machine tool cover 60 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com