Tractor used for cable

A tractor and cable technology, applied in the direction of cable laying equipment, etc., can solve the problems of cable surface wear, area reduction, wear, etc., to achieve the effect of easy pulling out cables, improving applicability and reducing obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

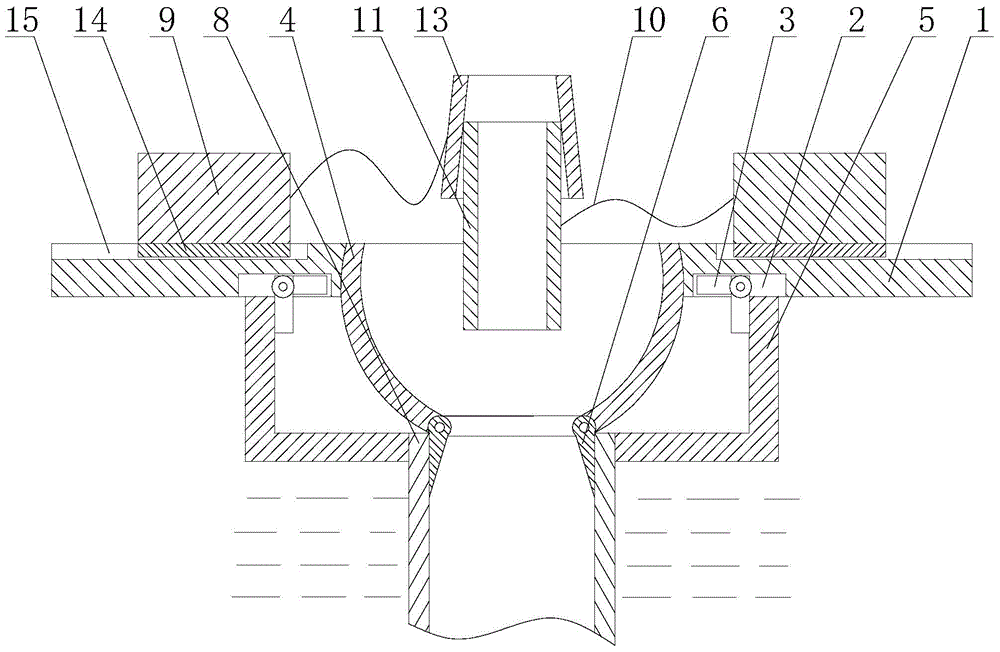

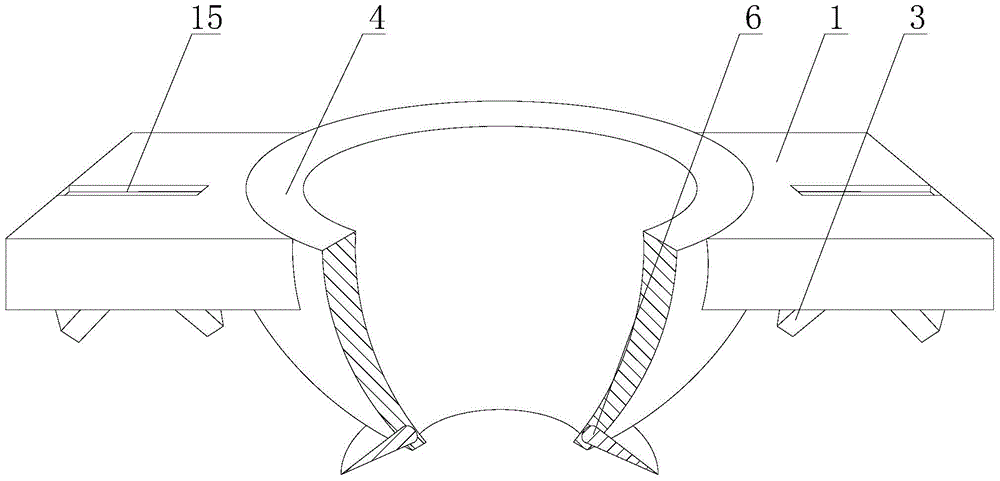

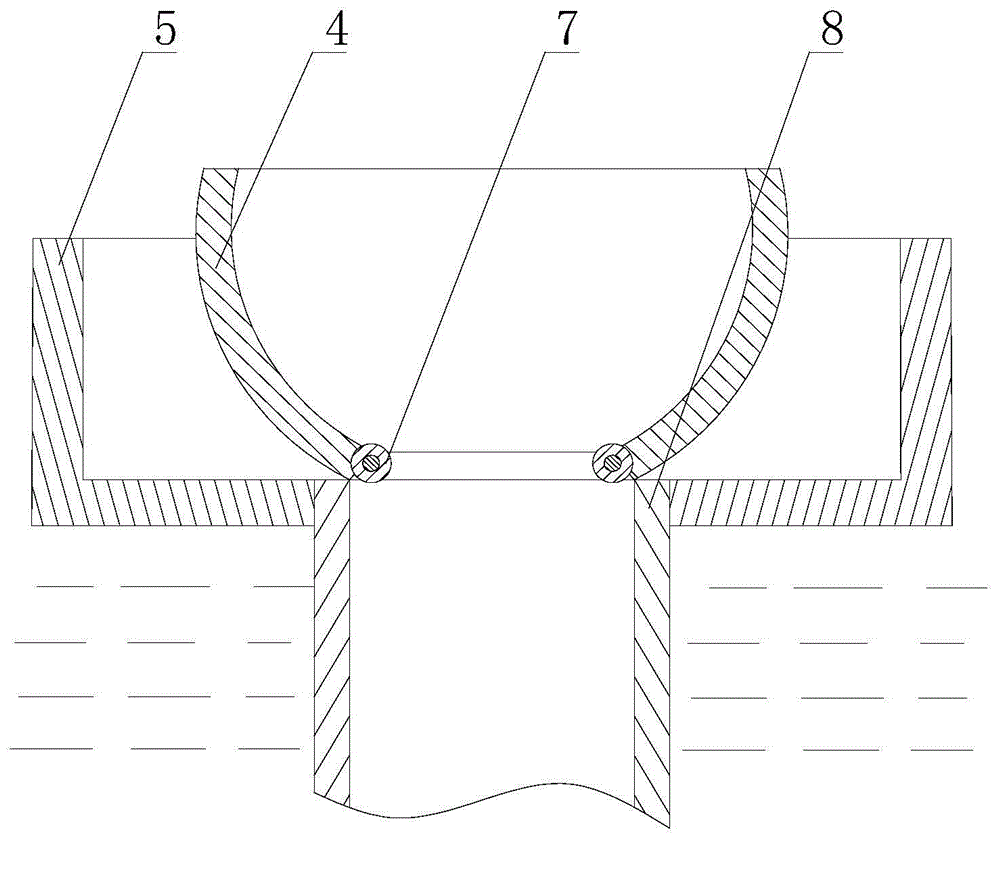

[0030] Such as Figure 1 to Figure 4 As shown, the retractor for cables includes a hemispherical body 4 with upper and lower ends open and hollow, and two supporting plates 1 fixed on both sides of the upper opening of the hemispherical body 4 respectively. The lower end surfaces of the two supporting plates 1 are all opened with In the blind hole 2, two snap-in plates 3 perpendicular to each other are rotated at the bottom of the blind hole 2 by the first torsion spring, the movable end of the snap-in plate 3 protrudes from the blind hole 2, and the edge of the opening at the lower end of the hemisphere 4 passes through the first torsion spring. The two torsion springs are rotated and provided with two oppositely arranged splints 6, and the edge is also provided with rollers 7 which are staggered with the splint 6; The sliding block 9 that the chute 15 moves and is arranged laterally, the opposite surfaces of the two sliding blocks 9 are provided with a drawing wire 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com