Multifunctional spliced ladder rib

A technology of splicing and ladder bars, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of high labor intensity, waste of ladder bar structure design, and high cost, so as to reduce labor intensity, facilitate loading and unloading, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

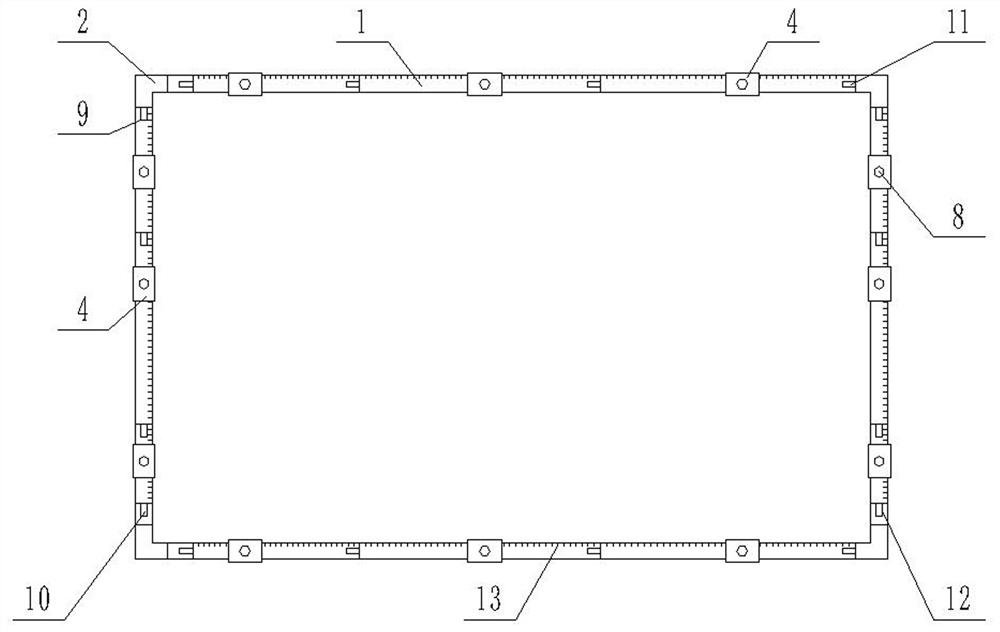

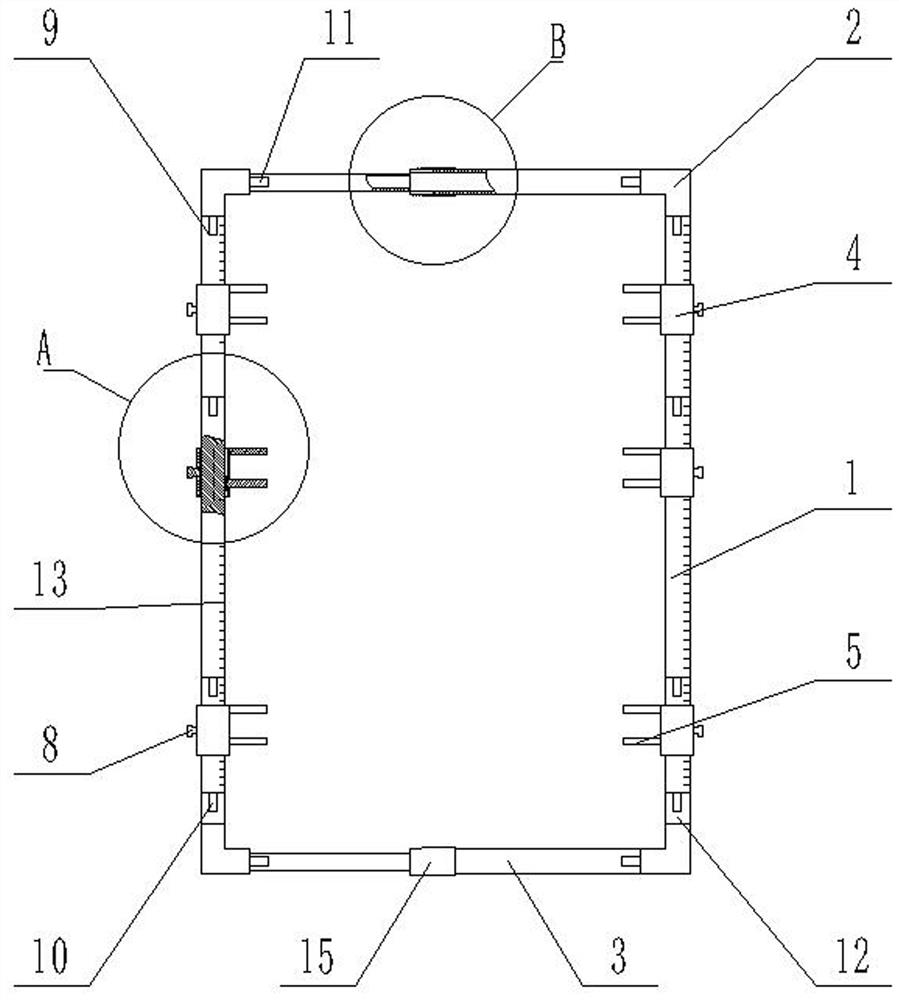

[0019] A multi-functional spliced ladder bar, including two frame bodies distributed front and rear, each frame body includes two main bars 1 arranged horizontally and two vertically, and a connecting link between the two adjacent main bars 1 is provided. The corner connectors 2 are provided with telescopic rods 3 connected between the front and rear corresponding corner connectors 2;

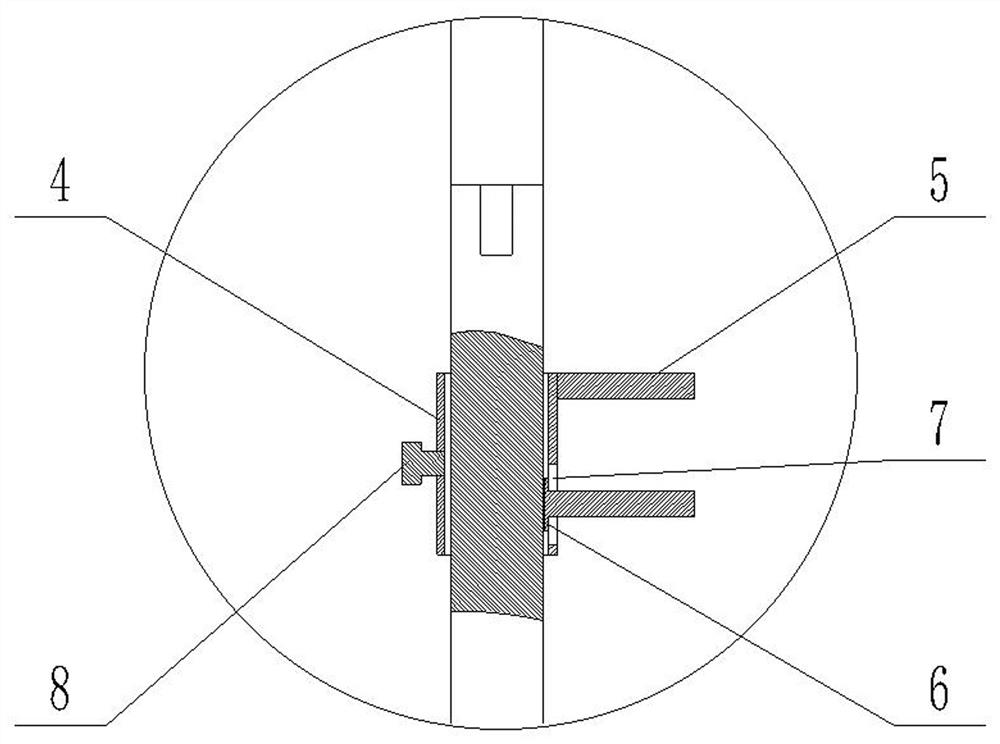

[0020] The main rods 1 of the two frame bodies are all covered with a number of steel bar ferrules 4, and the side walls of each steel bar ferrule 4 are provided with two steel bar clamping rods 5 located inside the two frame bodies, and one of the steel bar clamping rods 5 is connected to the The side wall of the reinforcing bar ferrule 4 is fixed, and another reinforcing bar clamping rod 5 penetrates in the side wall of the reinforcing bar ferrule 4, and the inner end of the reinforcing bar clamping rod 5 is fixed with an arc-shaped slide plate 6 cooperating with the reinforcing bar ferrule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com