Electric heating component

A technology of electric heating and components, which is applied in the direction of ohmic resistance heating components, the shape of heating elements, fluid heaters, etc., and can solve problems such as scaling, leakage, corrosion breakdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

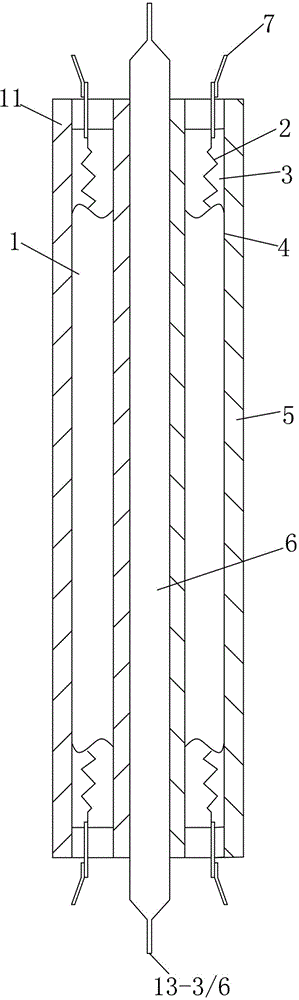

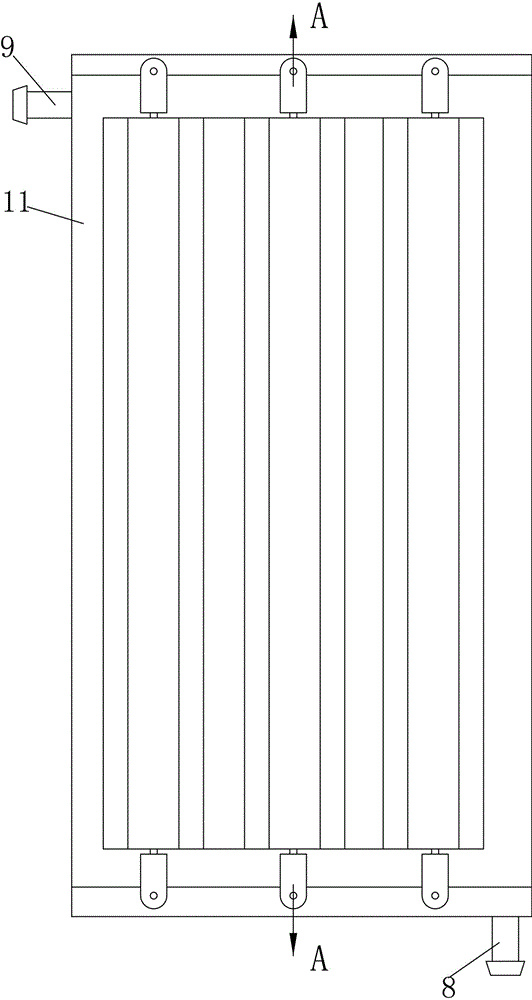

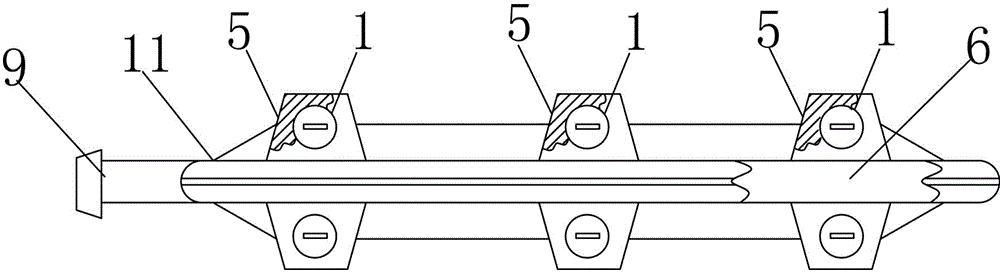

[0016] In the accompanying drawings, an electric heating component 11, an electric heating tube 1, an electric heating wire 2, magnesium oxide powder 3, a metal pipe 4, an aluminum alloy 5, a water flow channel 6 made of a metal material, a connection terminal 7, a water inlet port 8, and a water outlet port 9 .

[0017] figure 1 for figure 2 A-A sectional view, the electric heating tube 1 and the water flow channel 6 are wrapped by the aluminum alloy 5; the heat generated after the electric heating tube 1 is energized, passes through the aluminum alloy 5, and heats the water flowing in the water flow channel 6 by means of heat conduction; figure 2 is the outline drawing of the electric heating part, image 3 It is a top view; there are 6 electric heating tubes 1 in the figure, and there are 3 on each side. Depending on the structure and heating power, one or several can be used; the water flow channel 6 is flat in the figure, and can also be square or other shapes. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com