Dust removal method

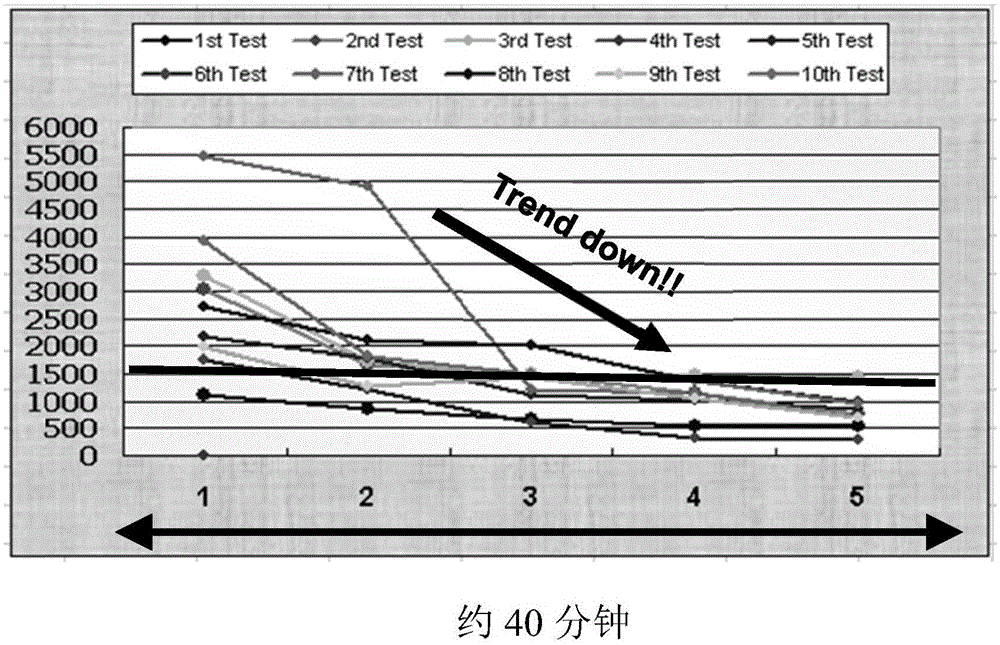

A technology for working chambers and pseudo-substrates, applied to cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of increasing manufacturing costs, consuming dust removal time, wasting pseudo-substrates, etc., to reduce manufacturing costs, reduce dust removal time, reduce The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A number of embodiments of the present invention will be disclosed in the following figures. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the present invention, these practical details are unnecessary.

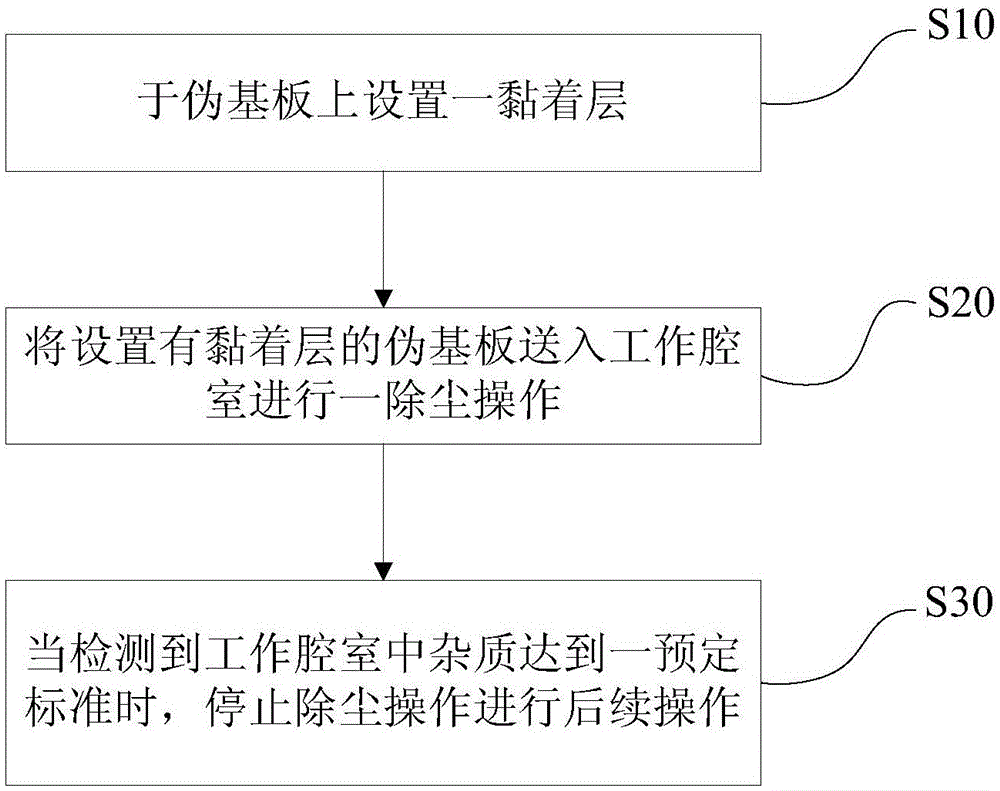

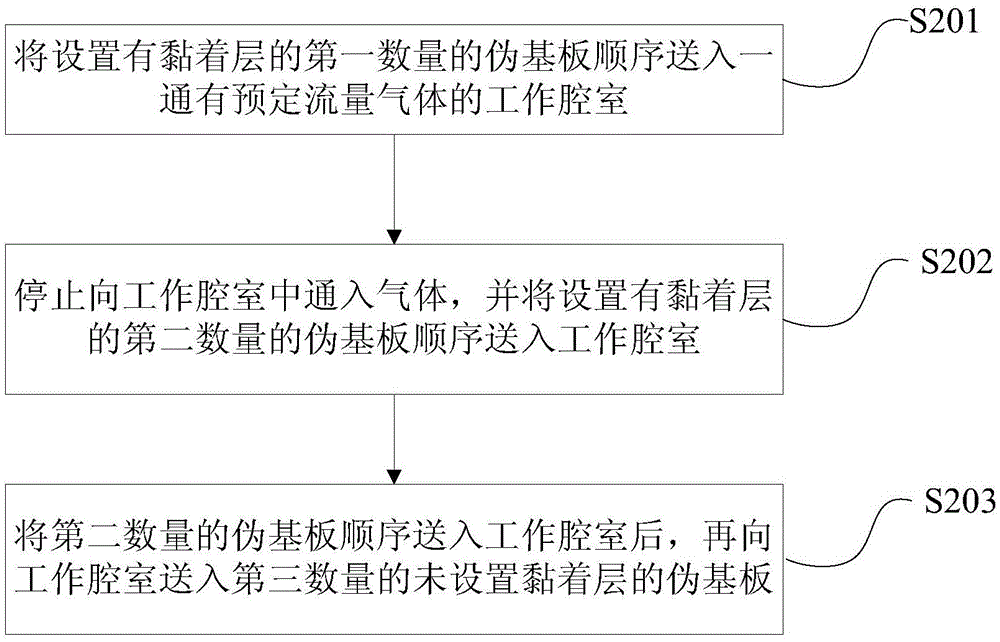

[0038] Such as figure 1 As shown, in one embodiment, the dedusting method of the present invention comprises the following steps:

[0039] S10: disposing an adhesive layer on the dummy substrate;

[0040] S20: sending the dummy substrate provided with the adhesive layer into a working chamber to perform a dust removal operation;

[0041] S30: When it is detected that impurities in the working chamber reach a predetermined standard, stop the dust removal operation and perform subsequent operations.

[0042] In step S10 of this embodiment, a layer of adhesive layer is attac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com