Sheet material for printed circuit board, seperation convying method of prepreg and seperation convying device

A technology of printed circuit boards and prepregs, which is applied in the field of prepreg separation and conveying devices, can solve problems such as scraping and not considering contact components, and achieve the effect of preventing scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] Hereinafter, an embodiment of the present invention (hereinafter referred to as an embodiment) and an embodiment of the present invention will be described in detail with reference to the drawings. In the embodiment example and each embodiment, descriptions of constituent elements (members or components) having the same function and shape, etc., are omitted by assigning the same reference numerals after once description, as long as there is no confusion.

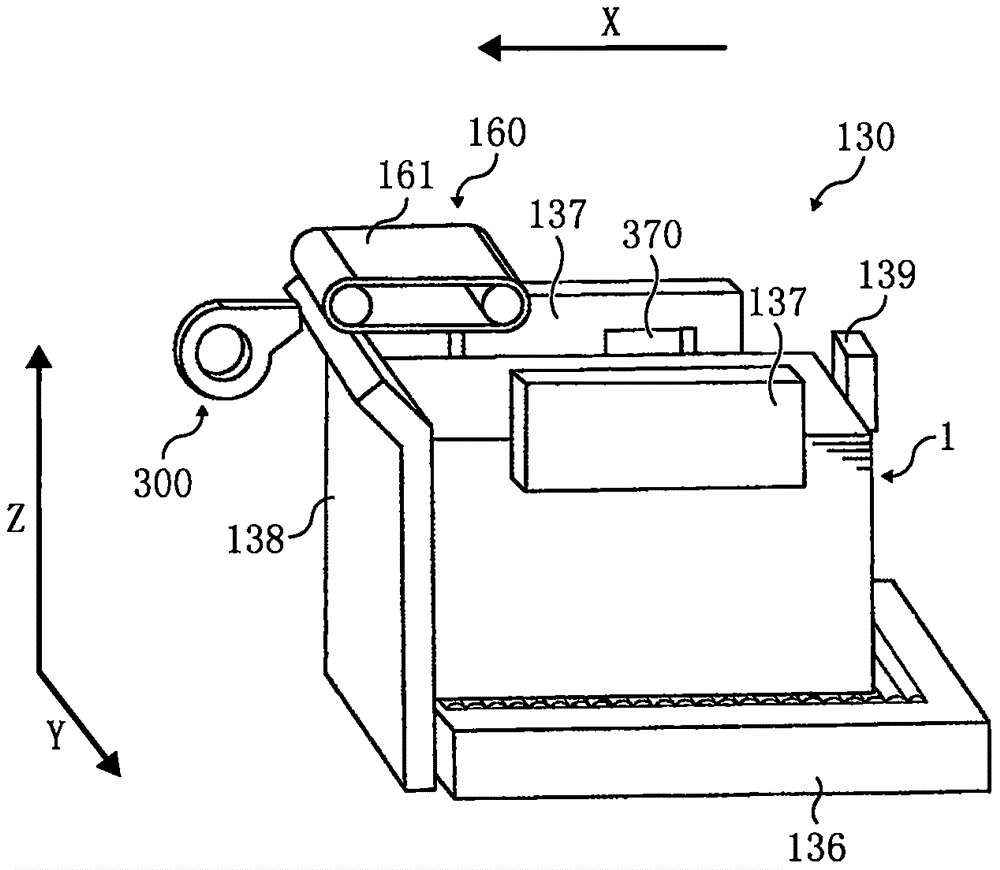

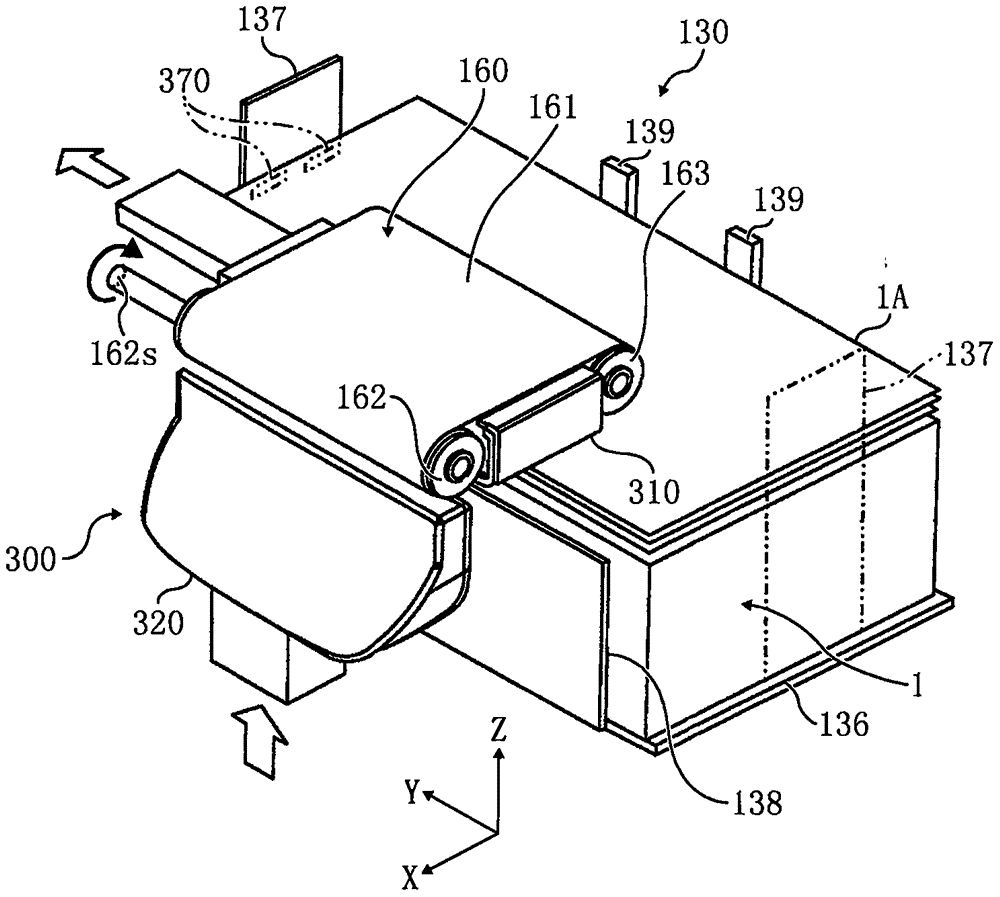

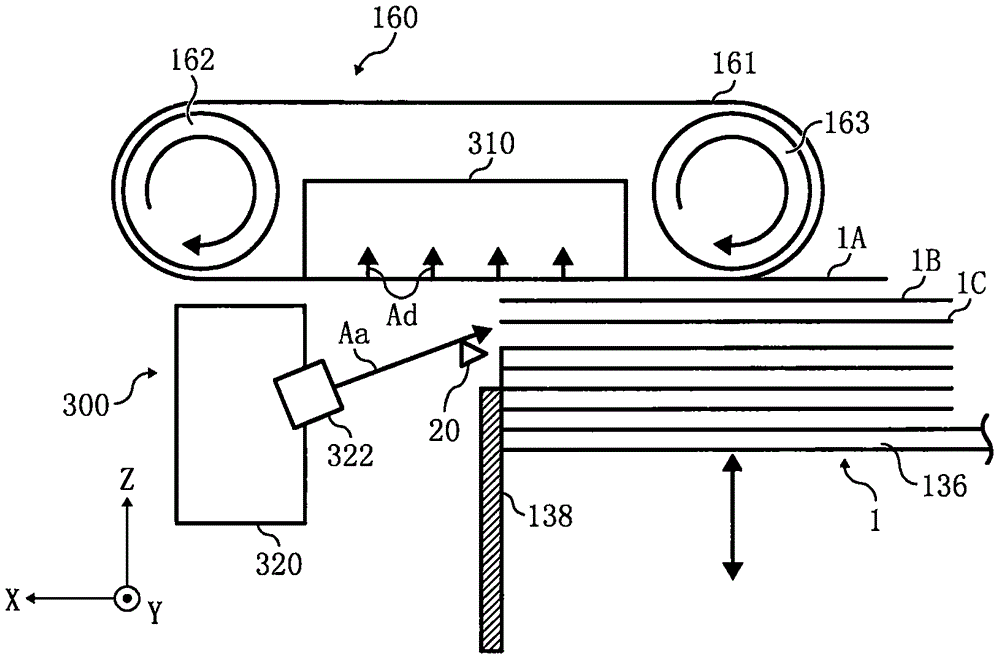

[0028] First, refer to Figure 1 to Figure 4 The separation and conveyance apparatus of the sheet|seat for printed wiring boards which concerns on embodiment example of this invention is demonstrated. figure 1 It is a schematic external perspective view of a separation and conveyance device for a printed circuit board sheet according to an embodiment of the present invention, figure 2 Shown is figure 1 Appearance perspective view of the separating and conveying device for printed circuit board sheets, image 3 Sho...

Embodiment approach 1

[0063] For the separating and conveying device for a printed wiring board sheet having the method of separating and conveying a printed wiring board sheet according to Embodiment 1 of the present invention and the holding part for implementing the method, the method for separating and conveying a printed wiring board sheet different from that of the embodiment example is used. The point of the sheet separating and conveying device 130 will be centered on the description. Figure 8 Shown is a partial cross-sectional side view of the floating holding conveying device constituting the separating conveying device for printed circuit board sheets used in Embodiment 1, Figure 9 Shown is a perspective view of the floating holding transfer device seen obliquely from the lower right. Figure 10 Shown is a perspective view illustrating belt holding regions of a plurality of conveyor belts of the floating holding conveyor device. Figure 11 Shown is a front view of the separated state ...

Deformed example 1

[0079] pass Figure 14 Modification 1 of Embodiment 1 will now be described. Figure 14 (a) is a front view of a separation and conveyance device for a printed wiring board sheet according to Modification 1 of Embodiment 1, Figure 14 (b) is a schematic front view showing the width of the printed wiring board sheet held by suction on the conveyor belt having a step according to Modification 1. FIG. Figure 14 The separation and conveyance apparatus 130B of the printed circuit board sheet shown in (a) and Figure 8 to Figure 12 Compared with the printed circuit board sheet separating and conveying device 130A, the difference is only that a plurality of (three in the illustrated example) floating holding and conveying devices 160A of Embodiment 1 are arranged side by side in the width direction Y. Thereby, the separating and conveying apparatus 130B of the printed wiring board sheet can float, separate, suck and hold, and convey, for example, a large-sized printed wiring board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap