Interconnected back plate

A backplane and board part technology, applied in the field of electronic equipment, can solve the problem that the backplane cannot meet more wiring requirements, and achieve the effect of meeting the wiring requirements, increasing the wiring area, and realizing electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

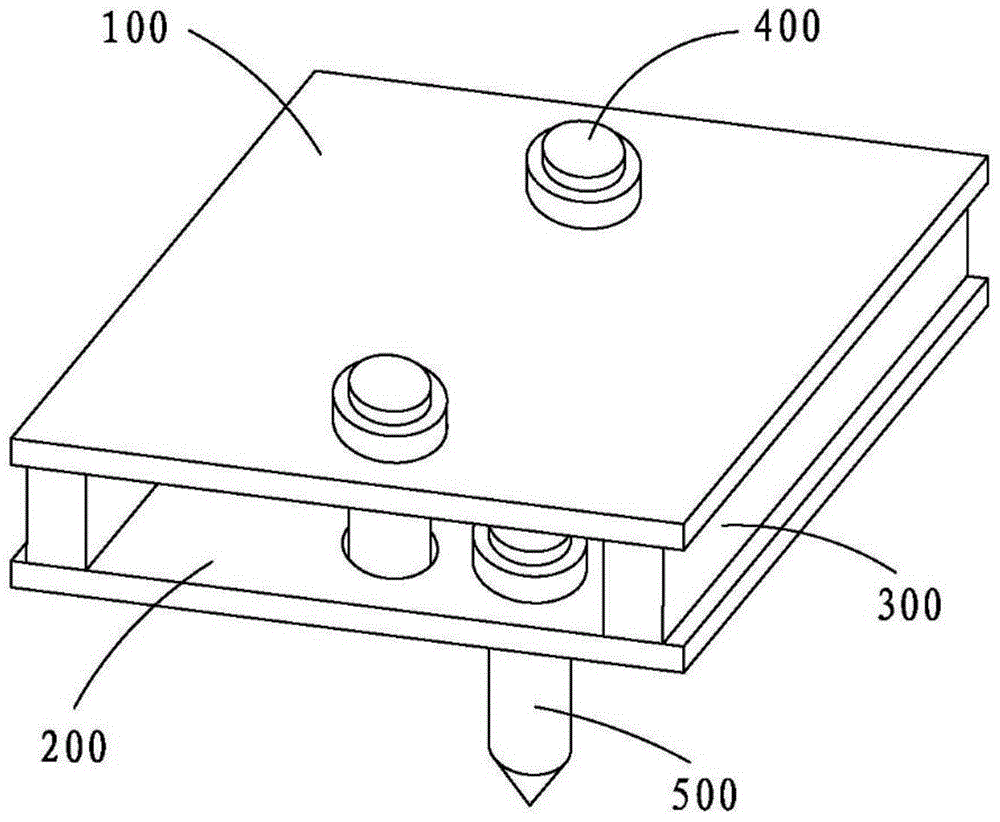

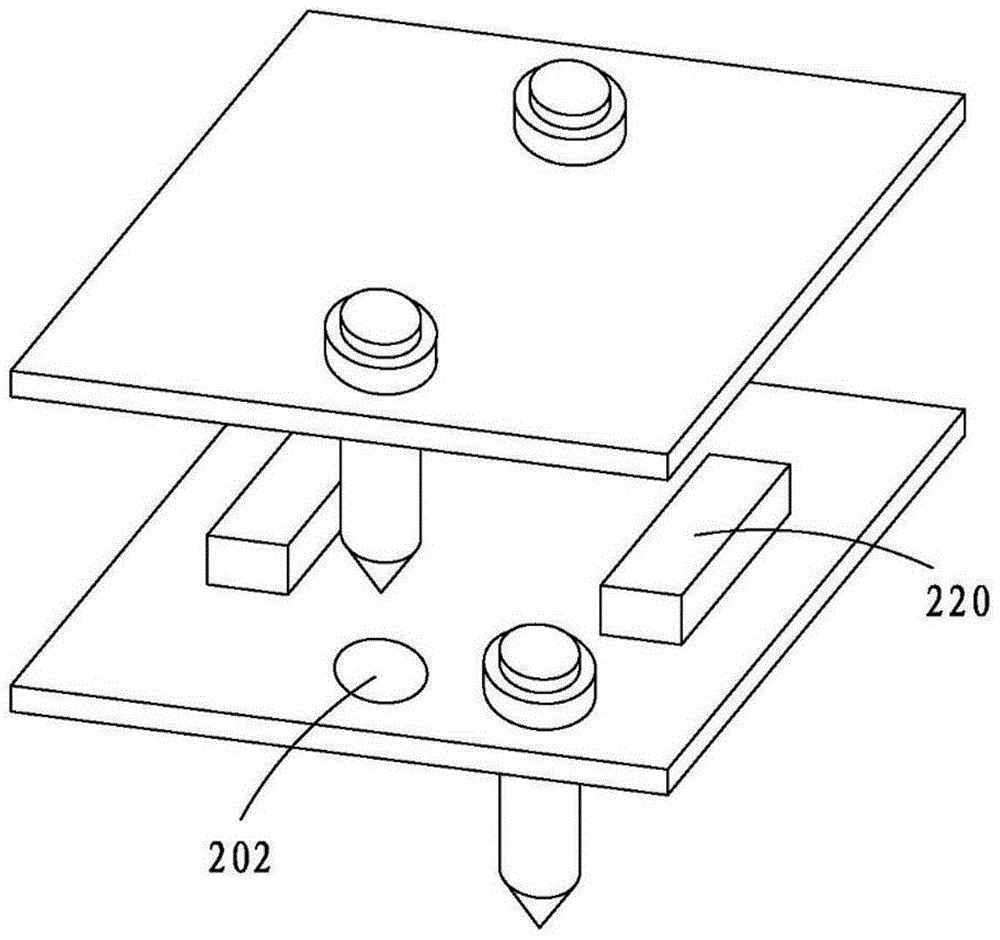

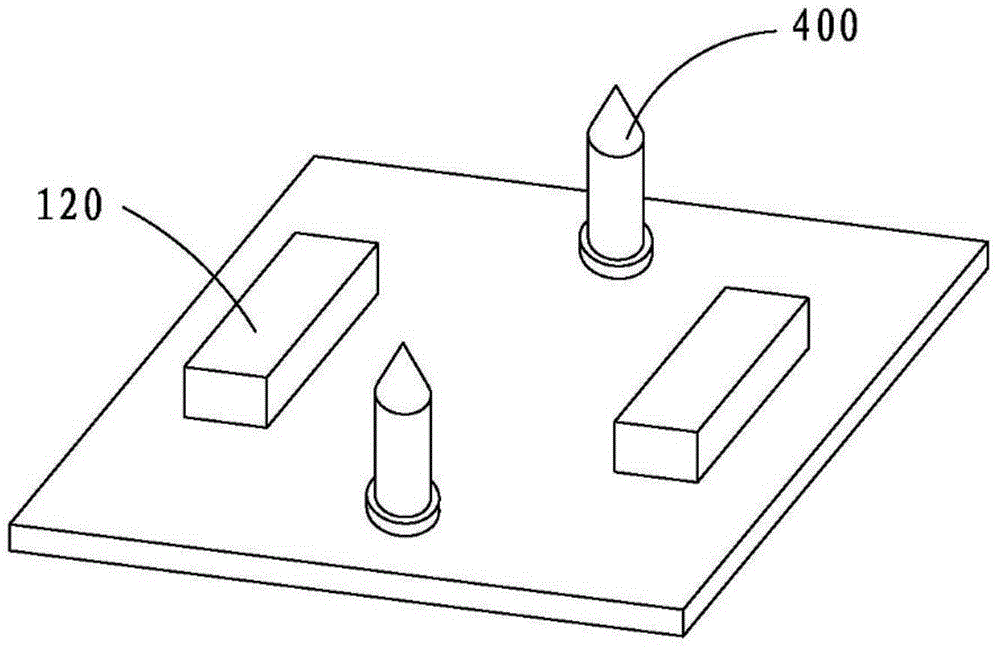

[0023] The present invention provides an interconnected backplane for installing circuit boards, referring to Figure 1 to Figure 3 In one embodiment, the interconnected backplane includes a first backplane unit 100 and a second backplane unit 200 stacked with the first backplane unit 100, and the first backplane unit 100 faces the second backplane unit 100. The surface of the second backplane unit 200 is provided with several first plug-in parts 120, and the surface of the second backplane unit 200 facing the first backplane unit 100 is provided with several first plug-in parts 120. The second plug-in part 220 is compatible, the first plug-in part 120 is plugged into the second plug-in part 220, so that the first backplane unit 100 and the second backplane unit 200 Fixed connection. In the interconnected backplane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com