Patents

Literature

32results about How to "Meet wiring needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric welding machine connecting device

ActiveCN106670692ALabor savingImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFrame basedSmall footprint

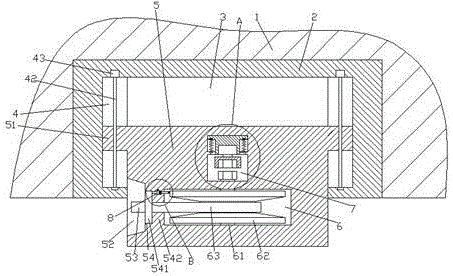

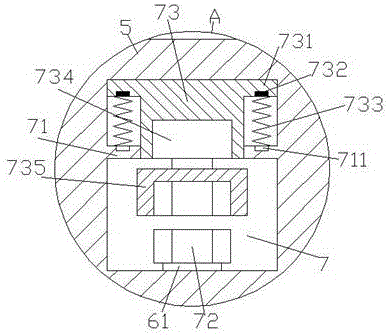

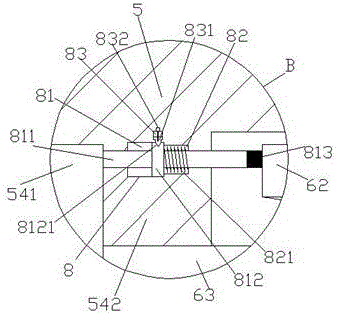

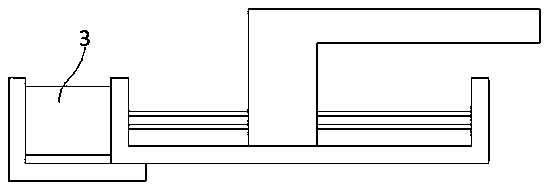

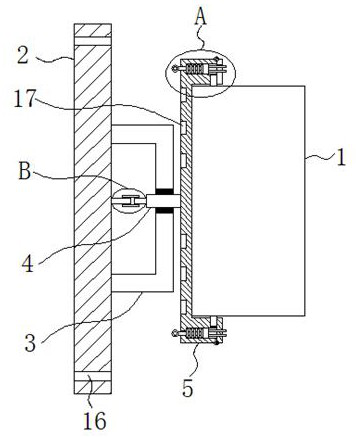

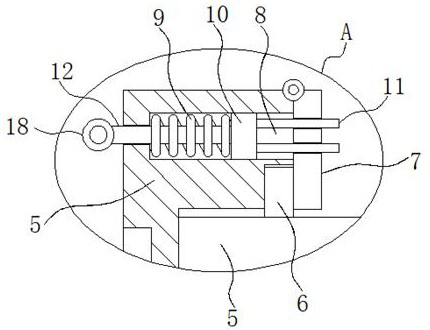

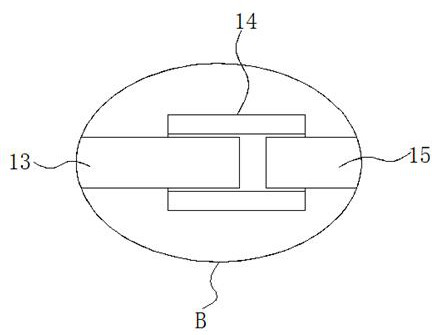

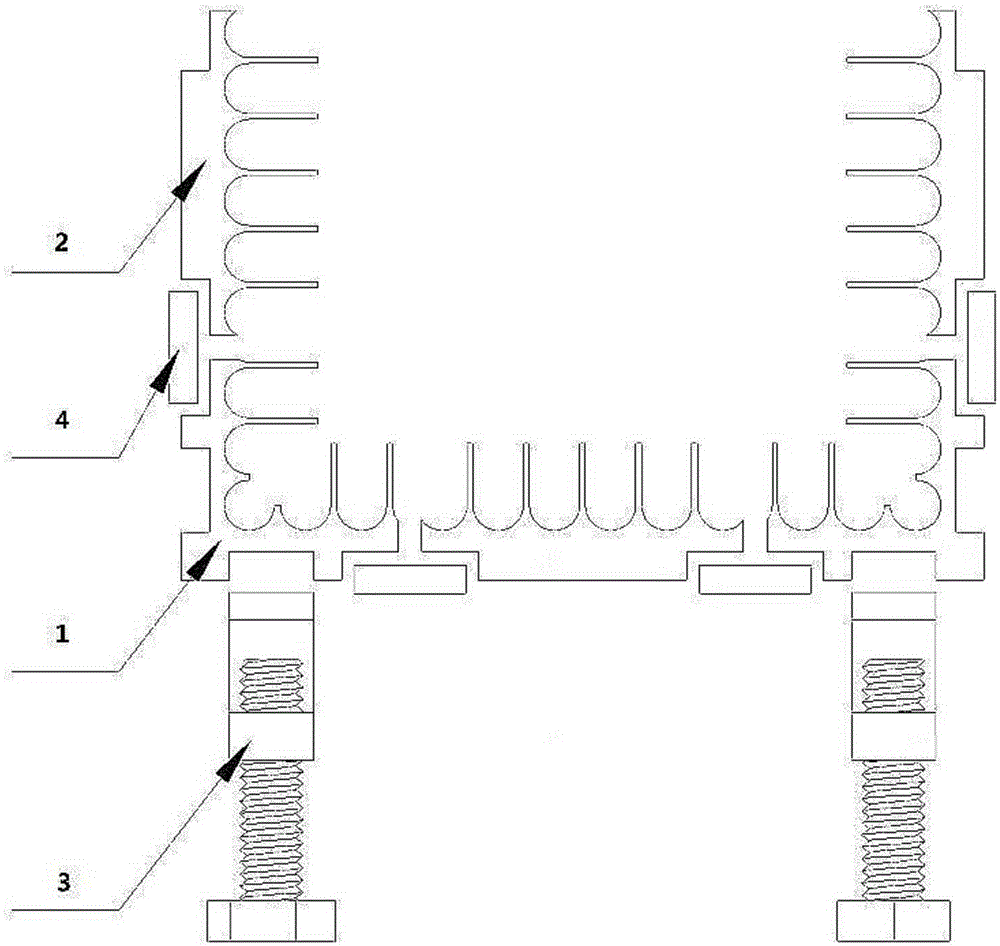

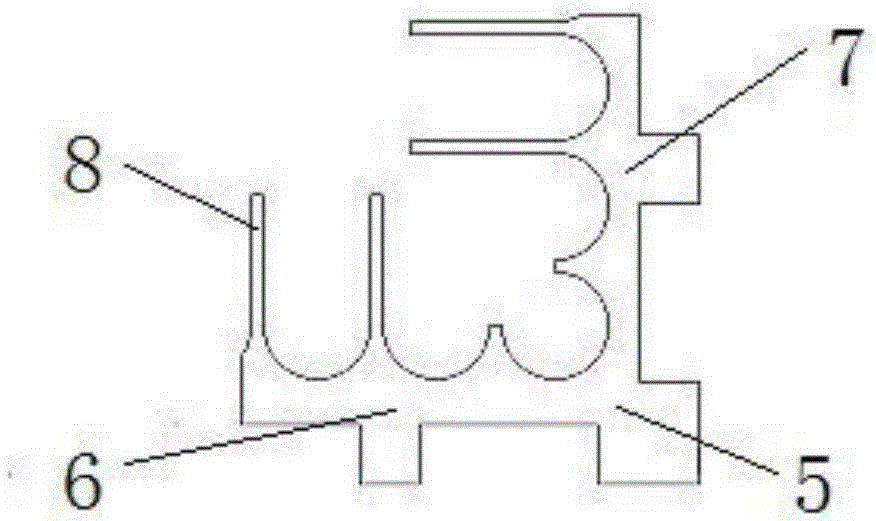

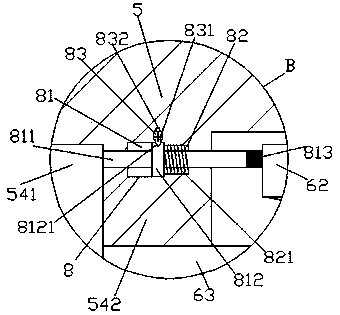

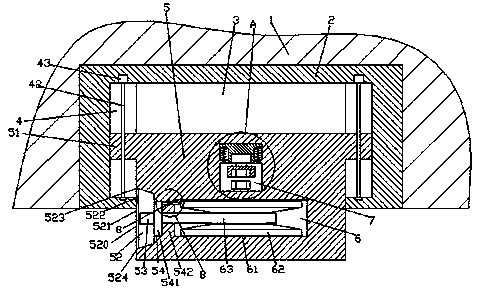

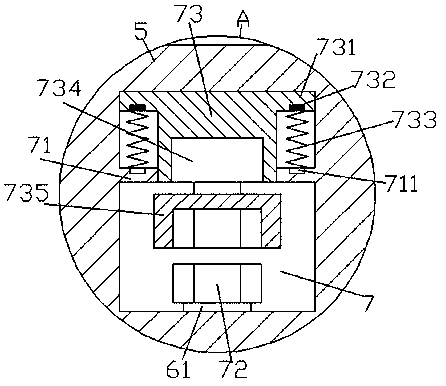

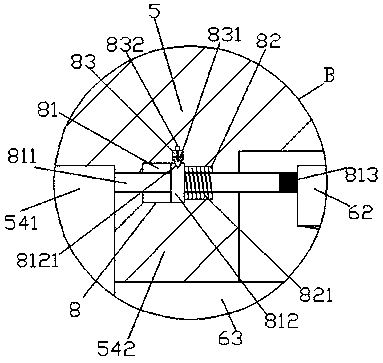

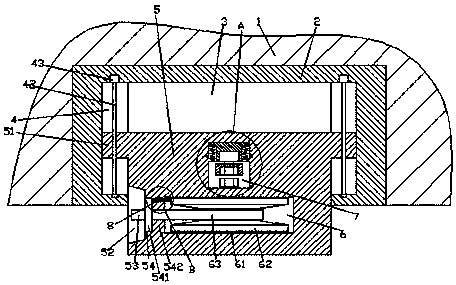

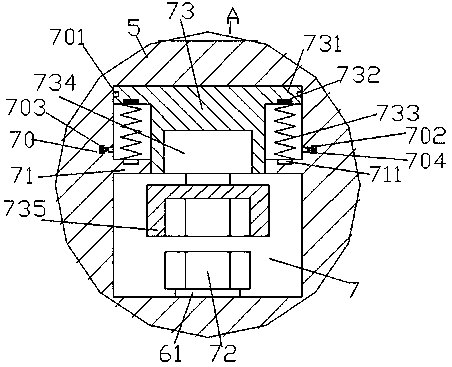

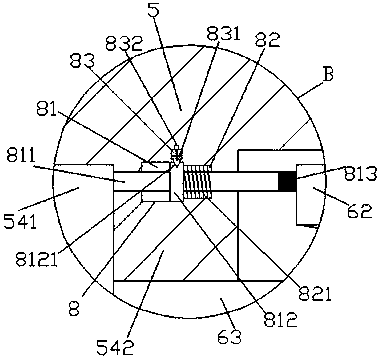

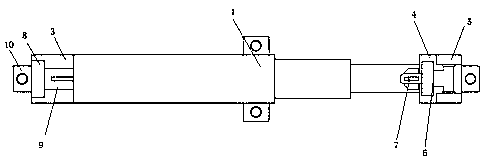

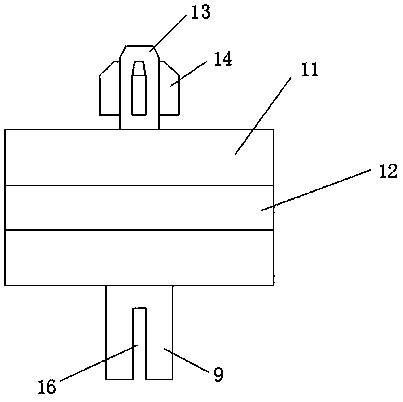

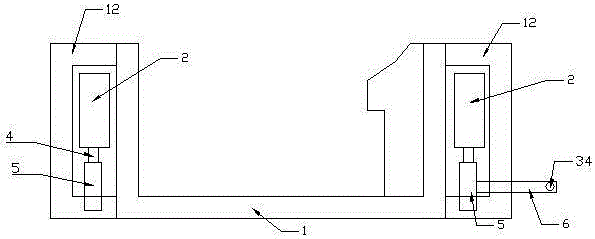

The invention discloses an electric welding machine connecting device which comprises a wall body and a frame base arranged in the wall body. A cavity is arranged at the bottom in the frame base, a slippage part is arranged in the cavity, a control zone is arranged in the outer wall of the left side of the slippage part, a placement groove is formed in the slippage part on the right side of the control zone, a first hollow cavity is formed in the slippage part on the right side of the placement groove, a first baffle is arranged between the first hollow cavity and the placement groove, a second hollow cavity is formed in the slippage part above the first hollow cavity, a first baffle is arranged in the second hollow cavity, a boss is arranged in the second hollow cavity above the first baffle, protruding blocks are arranged at the tops of two sides of the boss, magnets are arranged in the bottoms of the protruding blocks, magnets are arranged in the bottoms of the protruding blocks, electromagnetic coil devices are arranged at the top of the first baffle corresponding to the magnets, first compression springs are arranged between the electromagnetic coil devices and the magnets, and the bottom of the boss penetrates through the first baffle. The electric welding machine connecting device is simple in structure, convenient to operate, small in occupied area and capable of meeting wiring demands of different distances and achieving wire take-up work, and the working efficiency is improved.

Owner:江苏南洋电子有限公司

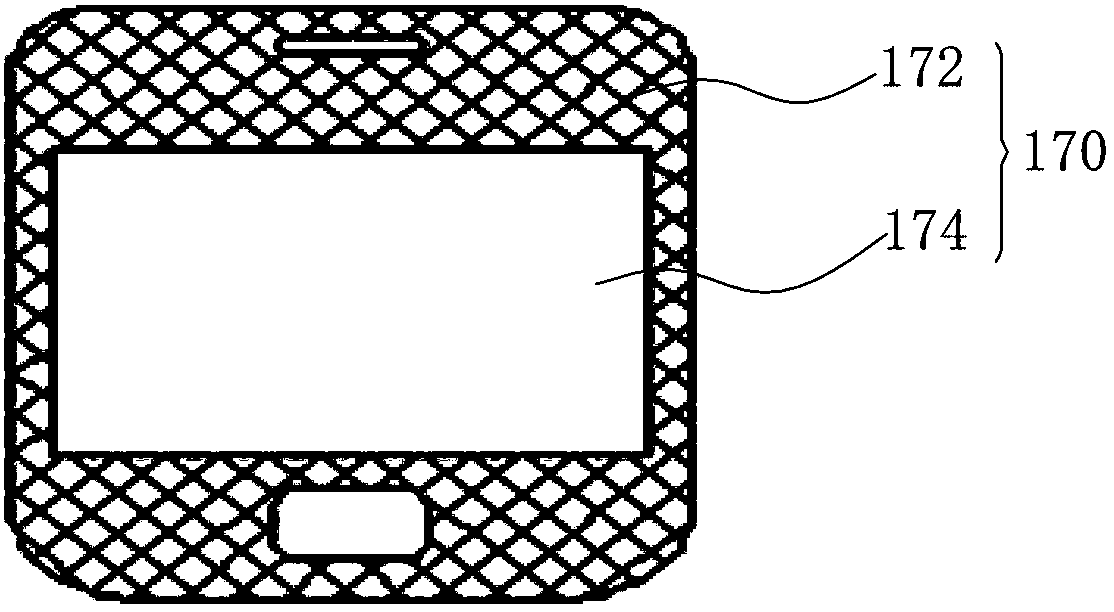

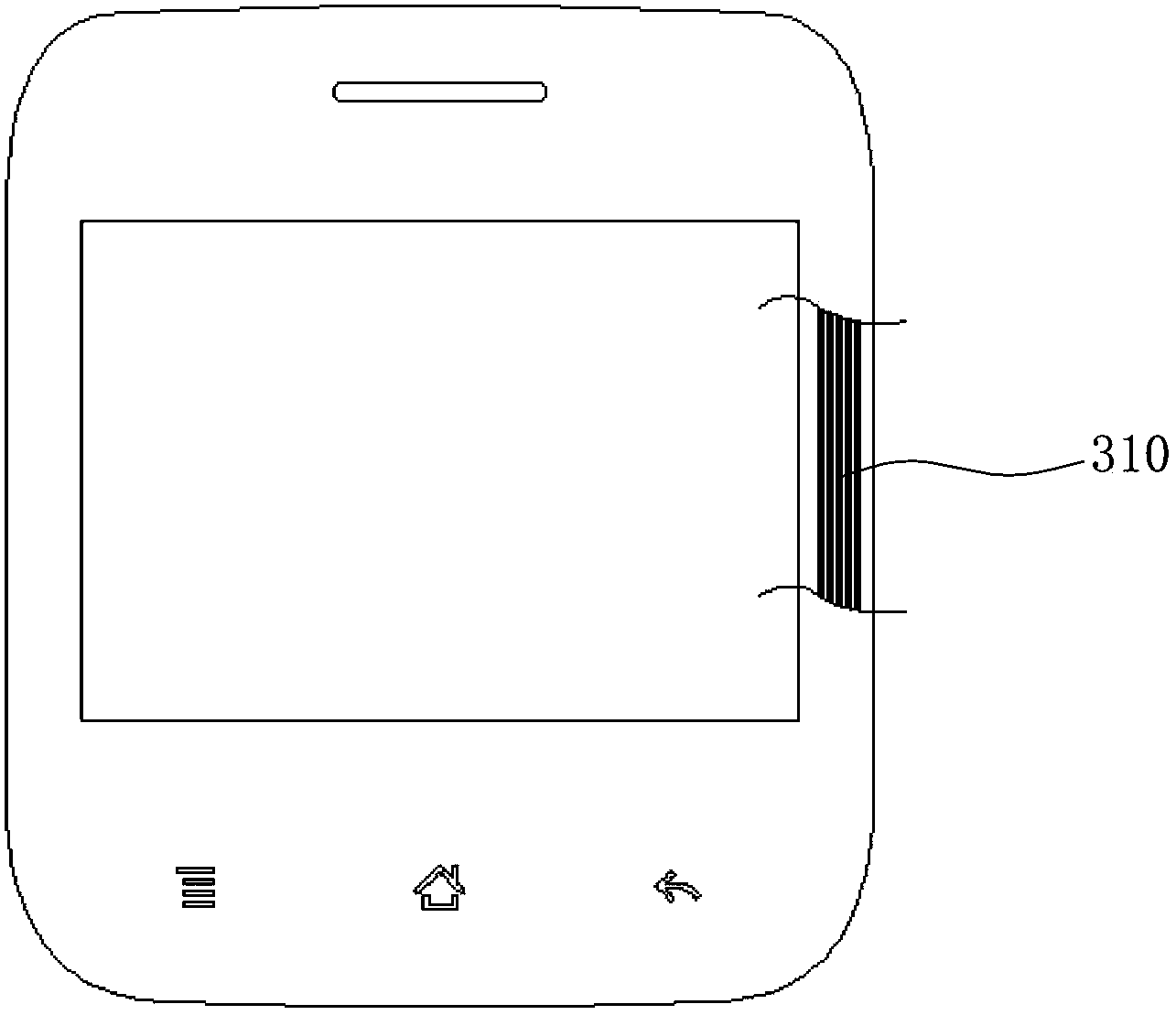

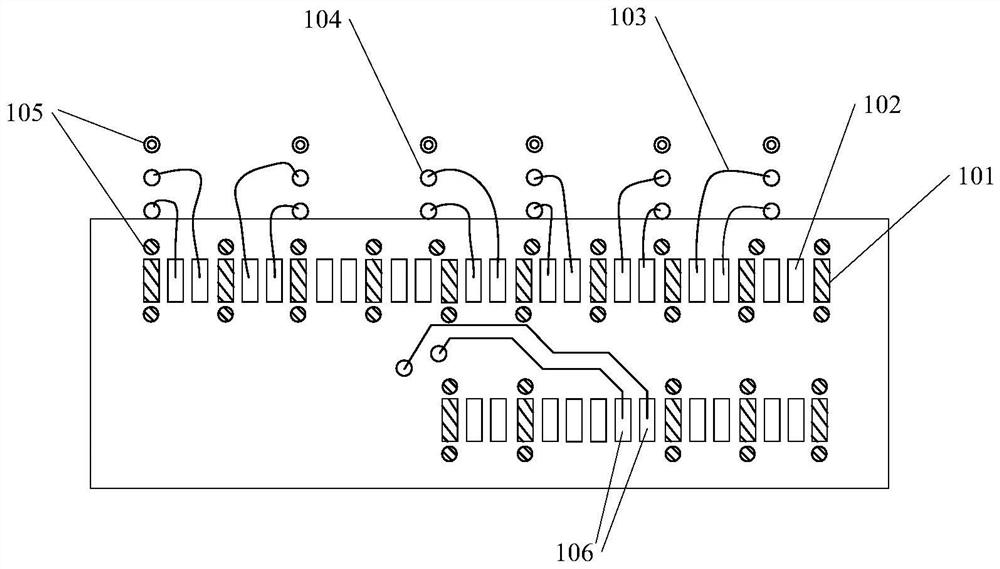

Capacitive touch screen and manufacturing method thereof

ActiveCN103543886AWill not affect workReduce borderInput/output processes for data processingCapacitanceEngineering

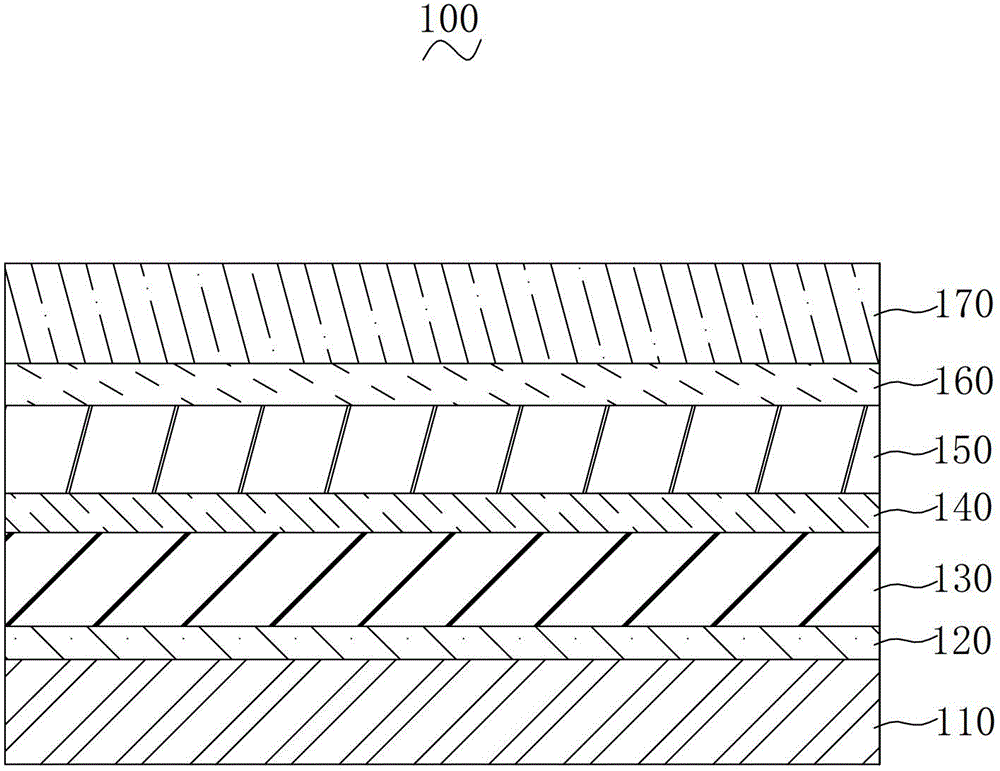

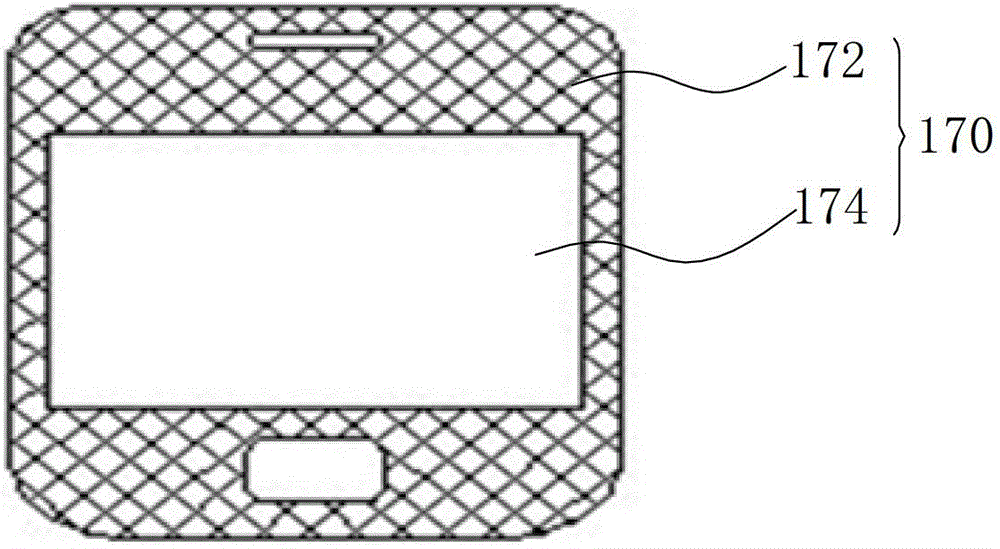

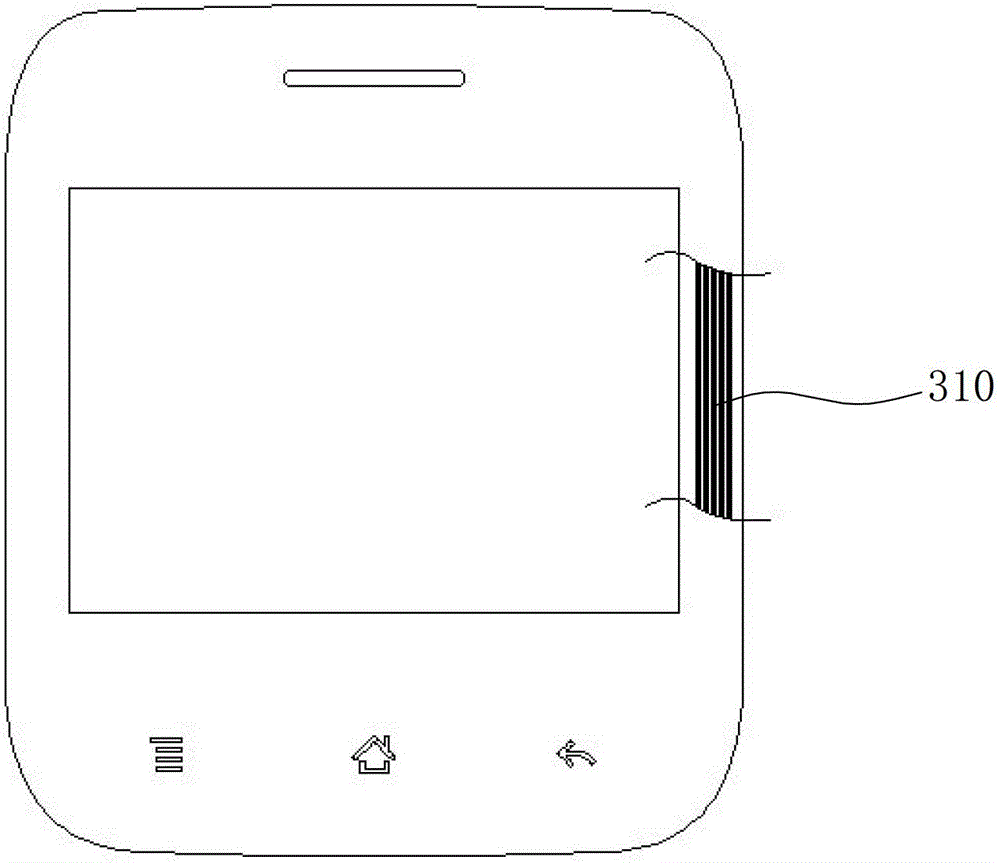

The invention relates to a capacitive touch screen. The capacitive touch screen comprises panel glass, and the panel glass comprises a touching area and a wiring area placed on the edge of the touching area. The capacitive touch screen further comprises an induction layer, a ground layer, a driving layer, a first circuit and a second circuit, wherein the induction layer, the ground layer and the driving layer are sequentially laminated on the touching area, the first circuit is led out from the induction layer, the second circuit is led out from the driving layer, and the first circuit and the second circuit are arranged in the wiring area of the panel glass in an overlapping mode. By the aid of the ground layer, two capacitors are formed by the driving layer and the ground, and the induction layer and the ground respectively, variations of the two capacitors are both led out in a grounding mode, hence, the capacitors formed by the induction layer and the driving layer are prevented, and when the first circuit and the second circuit are arranged in the wiring area in the overlapping mode, the work of the capacitive touch screen can not be affected; due to the fact that the first circuit and the second circuit are arranged in the overlapping mode, wiring space is greatly reduced, the size of the wiring area is decreased, a frame of the capacitive touch screen is made to be small, and the application of the capacitive touch screen can cater to light and thin large-window design. The invention further provides a manufacturing method of the capacitive touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

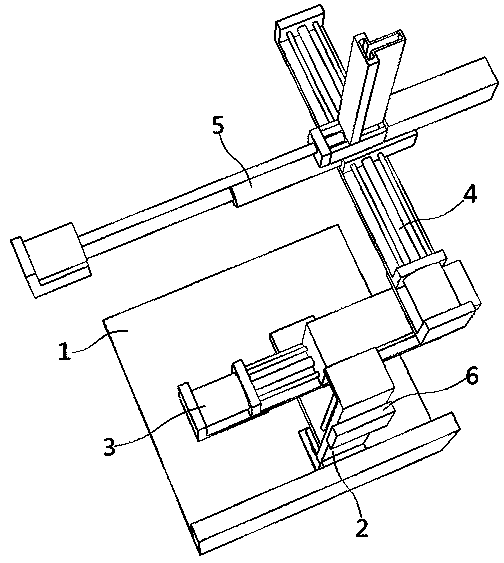

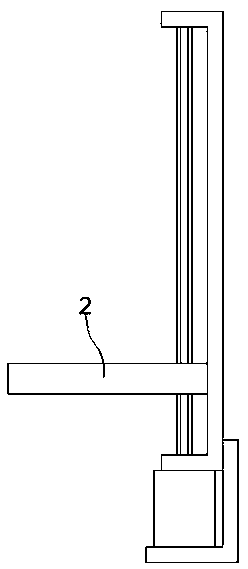

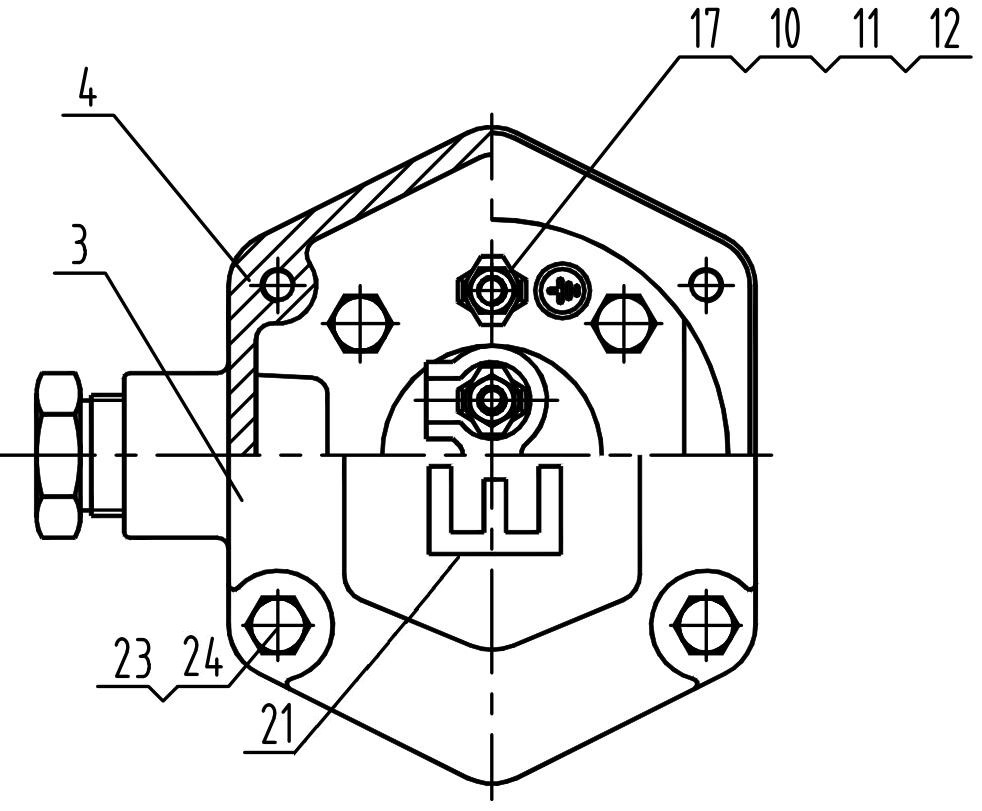

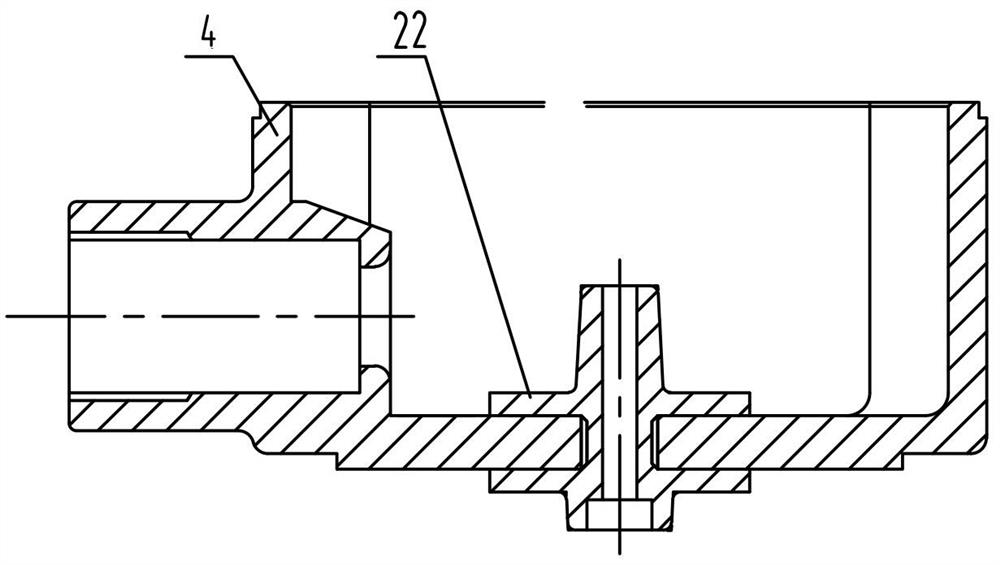

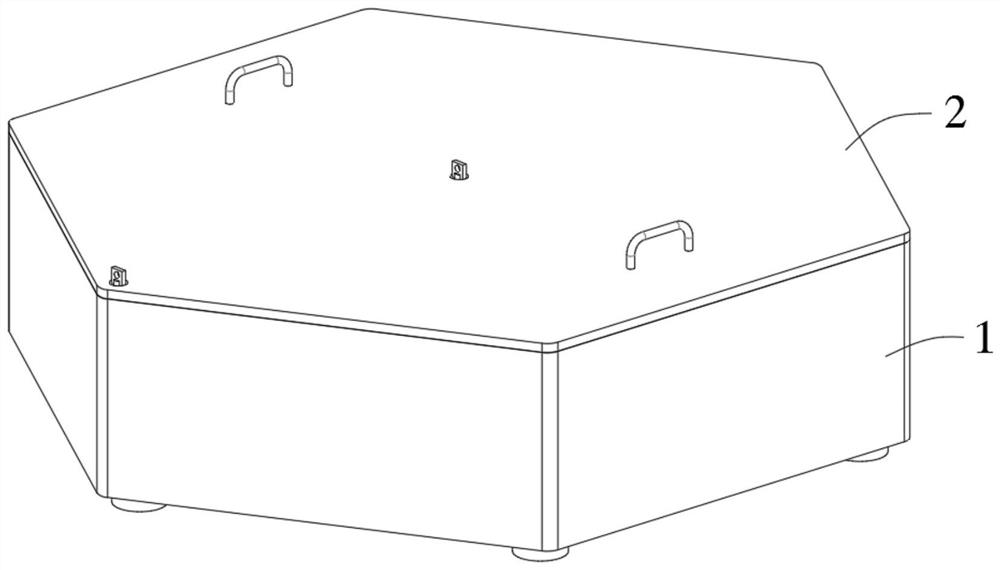

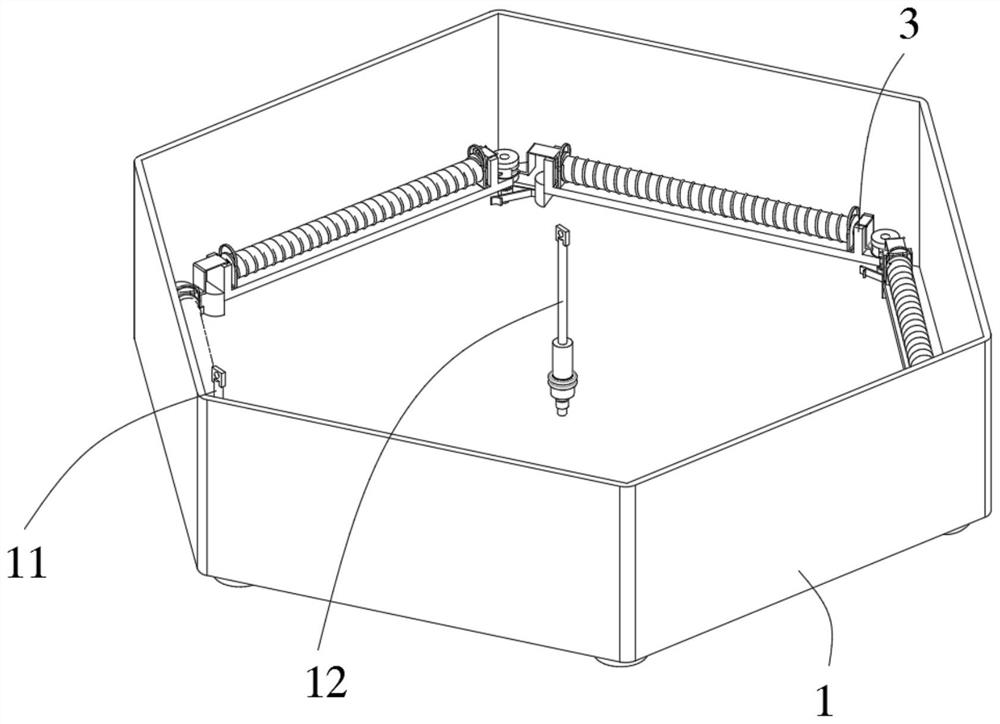

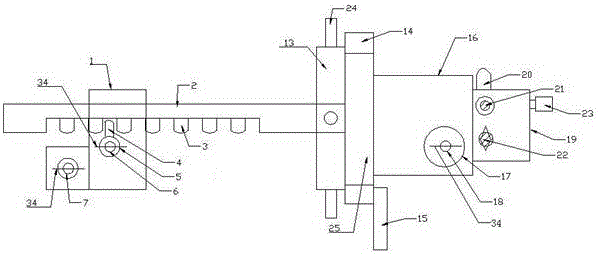

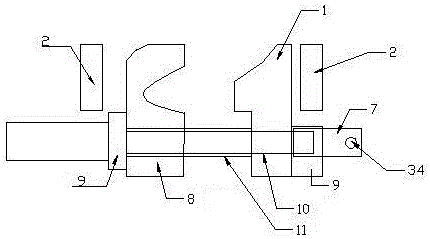

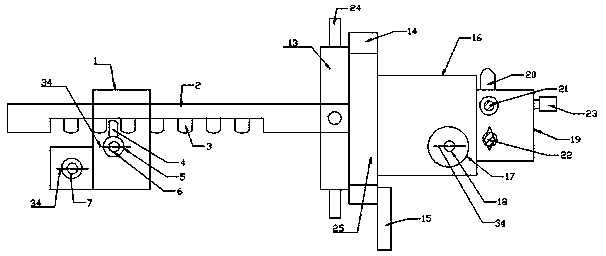

Automatic wiring robot for power distribution cabinet

InactiveCN110829253AImprove wiring efficiencyReduce the influence of human factorsLine/current collector detailsCable installation apparatusElectric machineControl theory

The invention discloses an automatic wiring robot for a power distribution cabinet, and relates to the technical field of power distribution cabinet wiring. The robot comprises a base. A first movingmechanism is fixed on one surface of the base. A second moving mechanism is fixed on the first moving mechanism. A third moving mechanism is fixed on the second moving mechanism. A wiring mechanism isfixed on the third moving mechanism. The third moving mechanism comprises a first U-shaped plate and a first sliding block. According to the invention, a PLC is used for controlling the wiring mechanism; an electric push rod in the wiring mechanism matches a second motor; a screwdriver rod is driven to push a square head screw falling into a second U-shaped plate to the wiring position of the power distribution cabinet; therefore, the square head screw is used for fixing a wire and the wiring position of the power distribution cabinet together; wiring processing of the power distribution cabinet is completed; the wiring efficiency of the power distribution cabinet is higher; the influence of human factors is smaller; the quality is more controllable; and the wiring requirements in the production and use process of the power distribution cabinet are better met.

Owner:九江清研神盾科技有限公司

Wall-mounted gateway convenient to install

InactiveCN112019429AConvenient thermal protectionConvenient position lockMachine supportsNetwork connectionsEngineeringStructural engineering

Owner:XIAN HUIFU RONGTONG INFORMATION TECH CO LTD

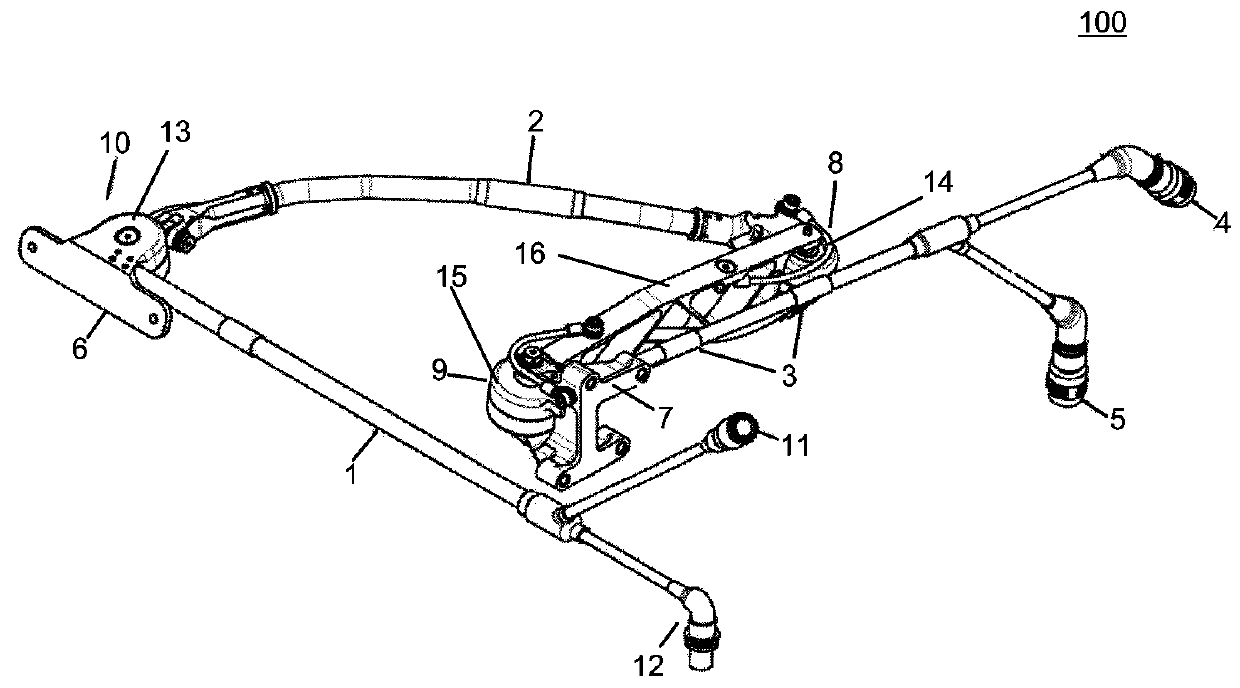

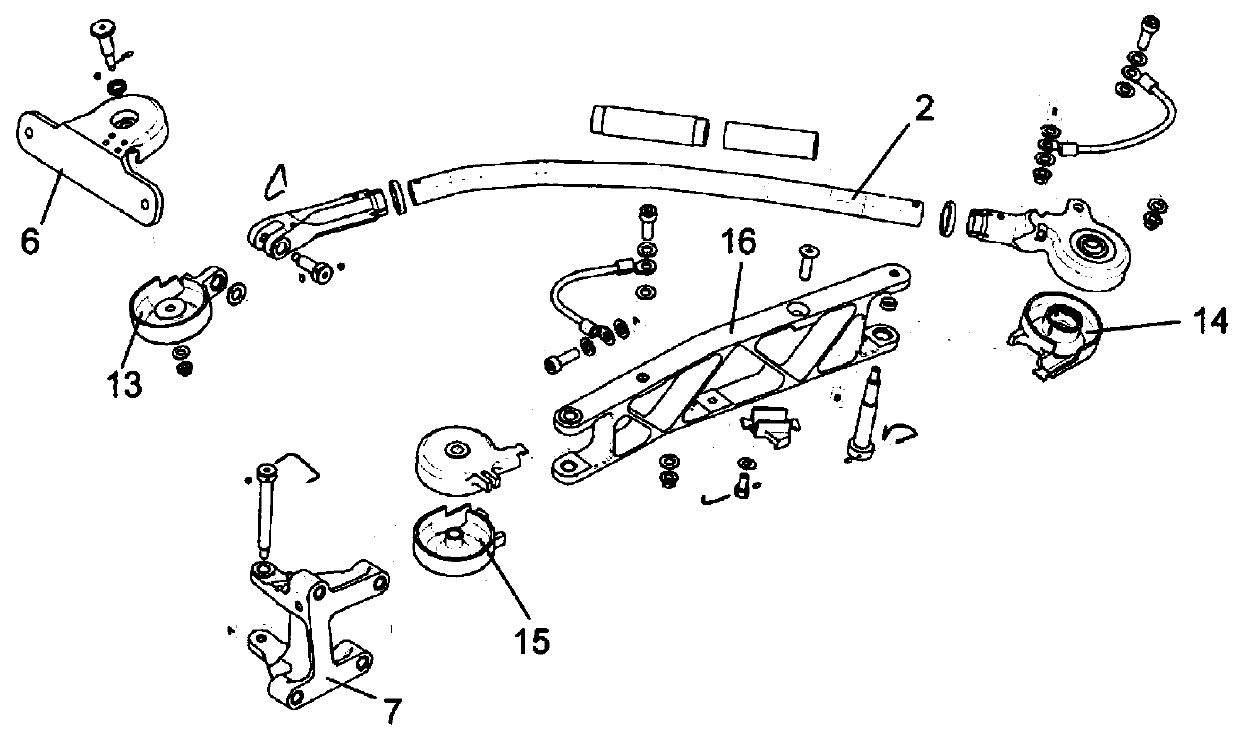

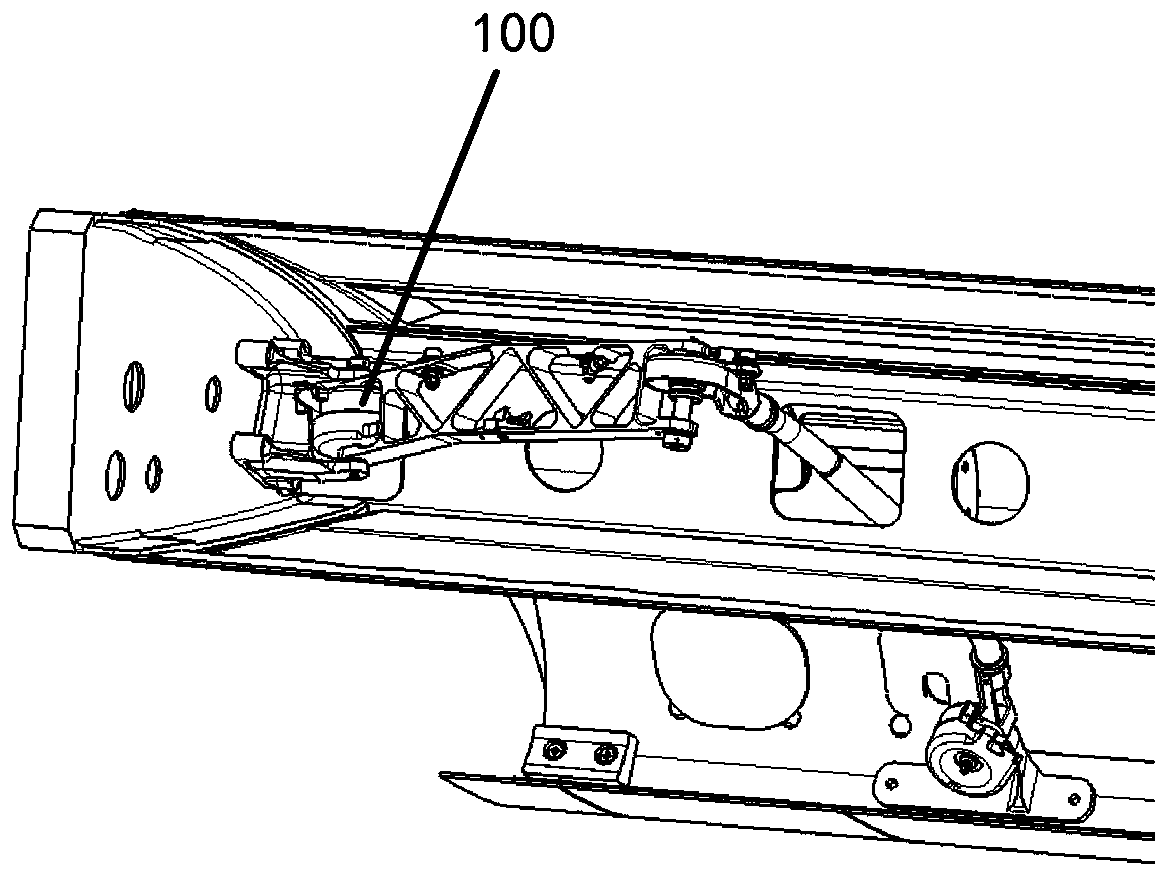

Rocker arm type moving cable mechanism

InactiveCN110641682AReduce the impact of aircraft weightAdapt to layout requirementsFuselagesSpherical motionKinematic pair

The invention discloses a rocker arm type moving cable mechanism which comprises a cable mechanical and electromagnetic interference protective sleeve arranged in a slat, a telescopic connecting rod,another cable mechanical and electromagnetic interference protective sleeve arranged at the wing leading edge, a connector arranged at the wing leading edge and used for connecting a wing leading edgebox section, a wing fixing leading edge bracket, a spherical kinematic pair, a rotary kinematic pair, a slat connector, wire winding boxes, and a connecting piece, wherein the wing fixing leading edge bracket is used for connecting the wing leading edge box section; the slat connector is used for butt joint of electric equipment and a wire harness in the slat; the wire winding boxes are mounted on the spherical kinematic pair and the rotary kinematic pair separately; and the connecting piece is used for connecting the spherical kinematic pair. The rocker arm type moving cable mechanism has the characteristic of being mounted in a narrow and small space and can be adapted to the moving cable arranging requirement of slat active surfaces of multiple airplane model numbers through adjustingthe parameter designs of all spherical kinematic pairs and the rotary kinematic pairs and size and shape design of all structural arms.

Owner:COMAC +1

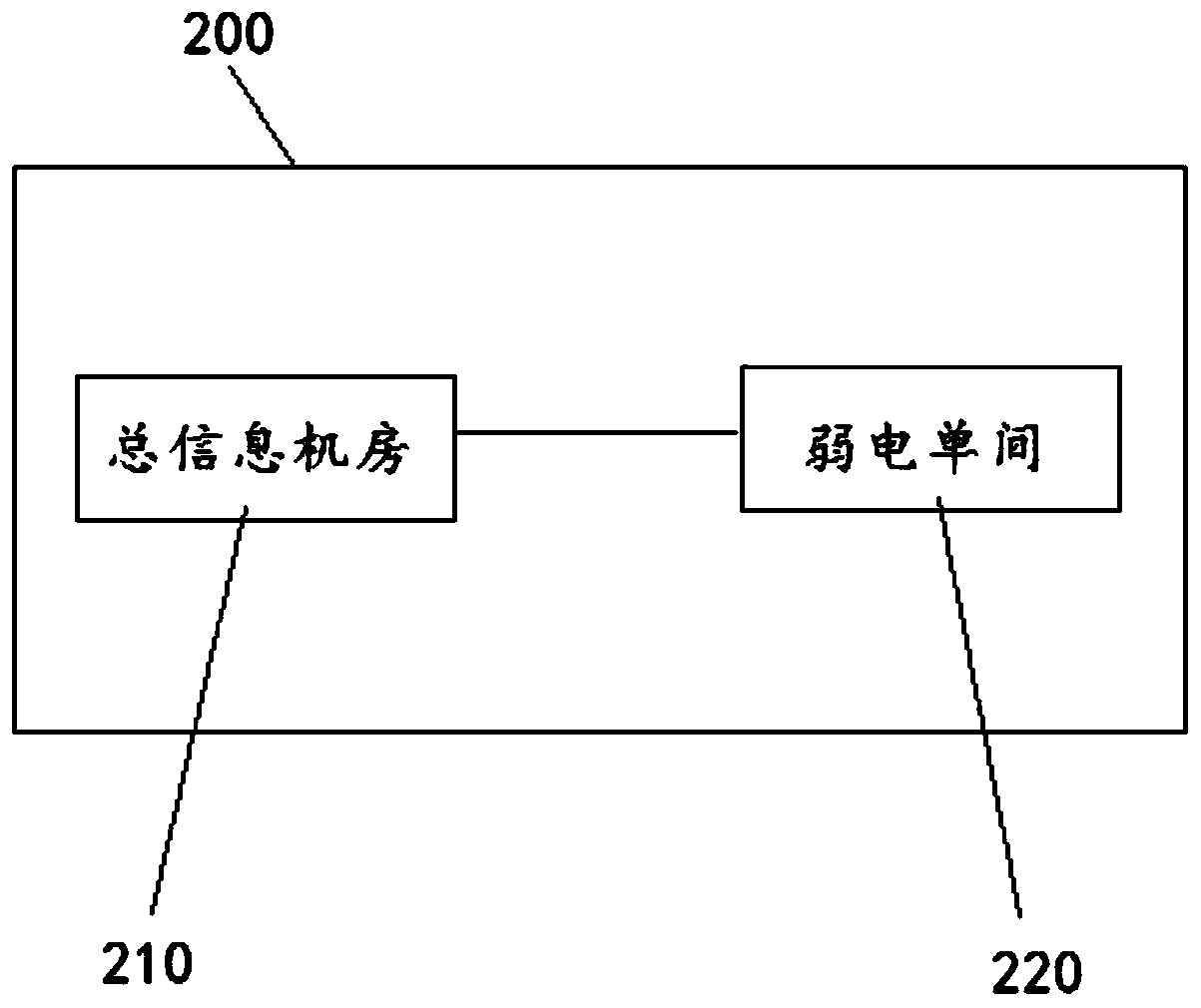

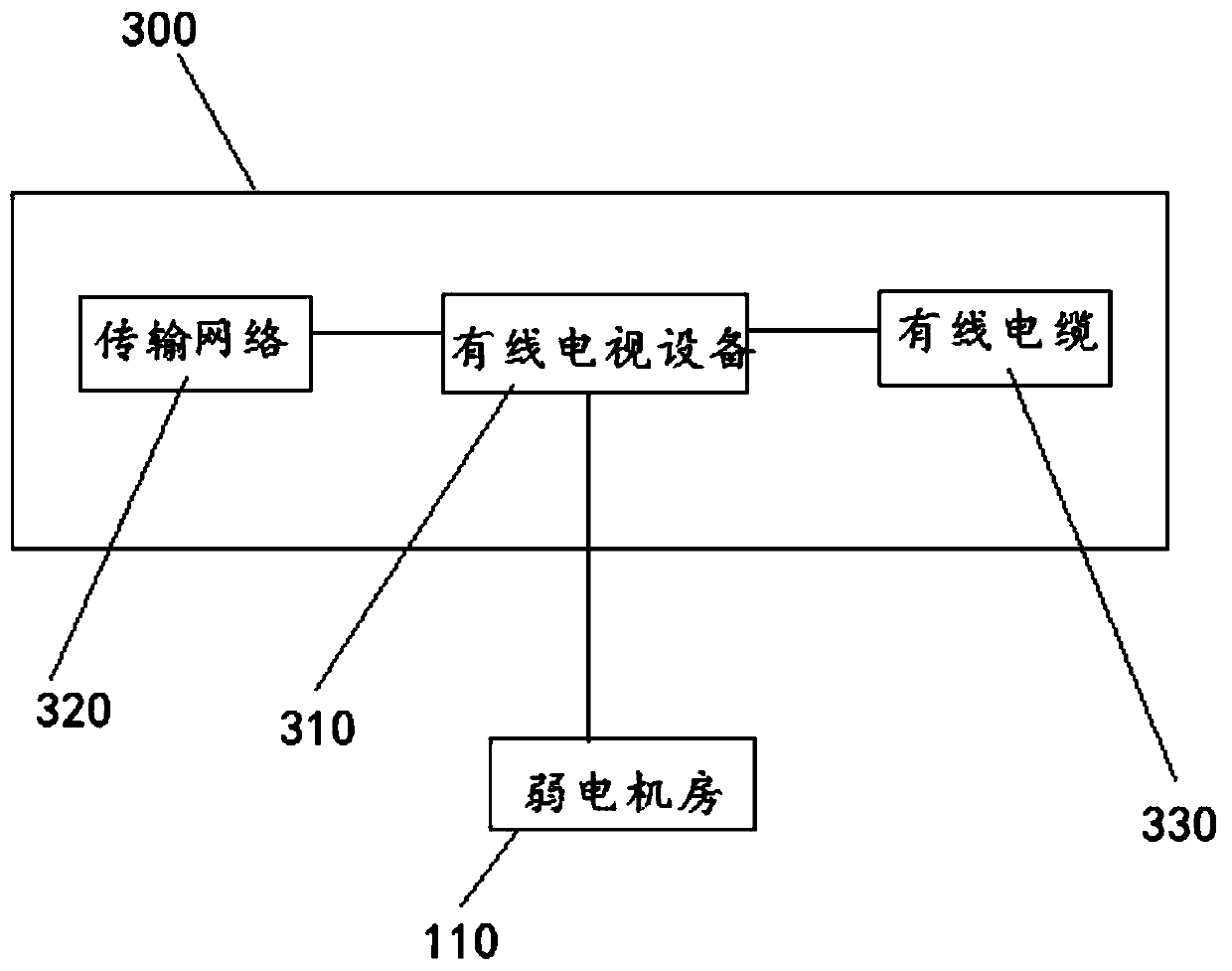

Building weak current system

InactiveCN111263098AAvoid shieldingHigh clarityFire rescueClosed circuit television systemsTelevision systemControl system

The invention relates to a building weak current system which comprises a telephone system, a comprehensive wiring system, a cable television system, a safety technology prevention system, an automatic fire alarm and fire-fighting linkage control system and a garage access management system. According to the invention, the safety is improved.

Owner:上海徐汇规划建筑设计有限公司

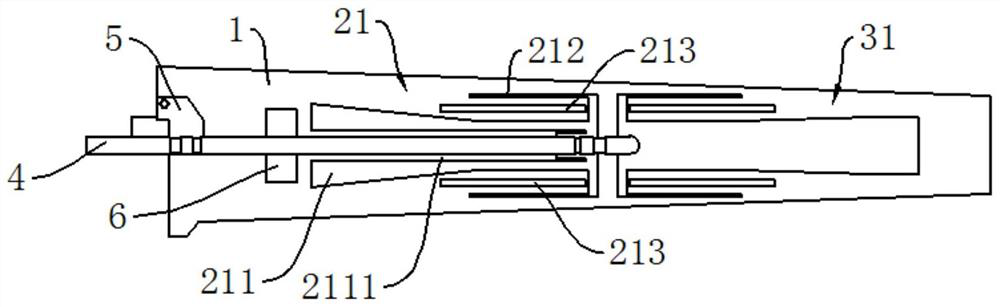

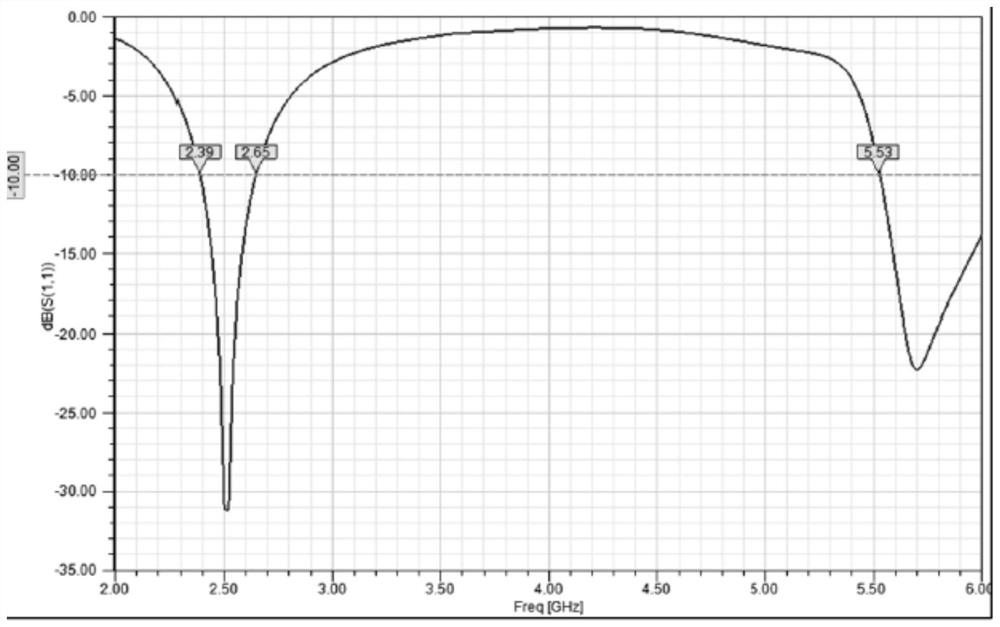

Unmanned aerial vehicle external dual-frequency antenna and unmanned aerial vehicle

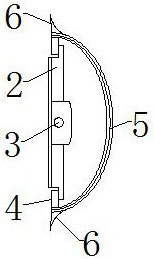

PendingCN112909535AMeet the signal coverageMeet wiring needsAntenna adaptation in movable bodiesRadiating elements structural formsUncrewed vehicleCoaxial line

The invention belongs to the technical field of unmanned aerial vehicles, and particularly discloses an unmanned aerial vehicle external dual-frequency antenna and an unmanned aerial vehicle. The unmanned aerial vehicle external dual-frequency antenna comprises a substrate, a low-frequency oscillator area, a high-frequency oscillator area, a feed coaxial line and grounding ends, and the two grounding ends are electrically connected with the feed end of the feed coaxial line; the low-frequency oscillator area or the high-frequency oscillator area is provided with an avoiding area used for arranging the feed coaxial line; the low-frequency oscillator area comprises a first low-frequency oscillator area and a second low-frequency oscillator area; and the high-frequency oscillator area comprises a first high-frequency oscillator area and a second high-frequency oscillator area which are asymmetrically arranged on the front and back surfaces of the substrate up and down. According to the unmanned aerial vehicle external dual-frequency antenna, the first low-frequency oscillator area and the second low-frequency oscillator area, and the first high-frequency oscillator area and the second high-frequency oscillator area are arranged in a positive and negative asymmetrical manner so that the wiring requirement in a relatively small space can be met, the circuit layout is more reasonable, and meanwhile, the signal coverage of dual frequency bands of 2.4 GHz and 5.8 GHz can be met.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

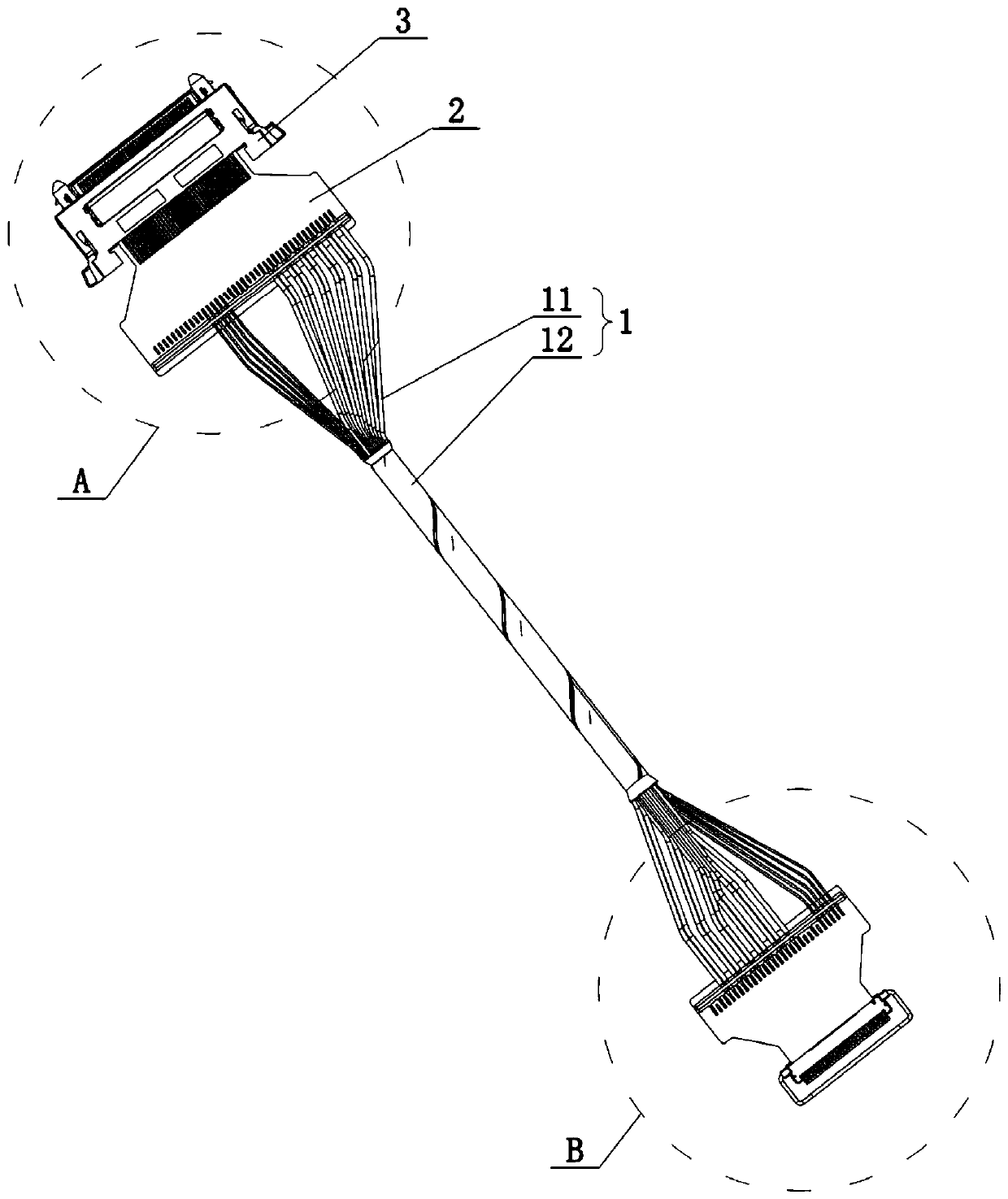

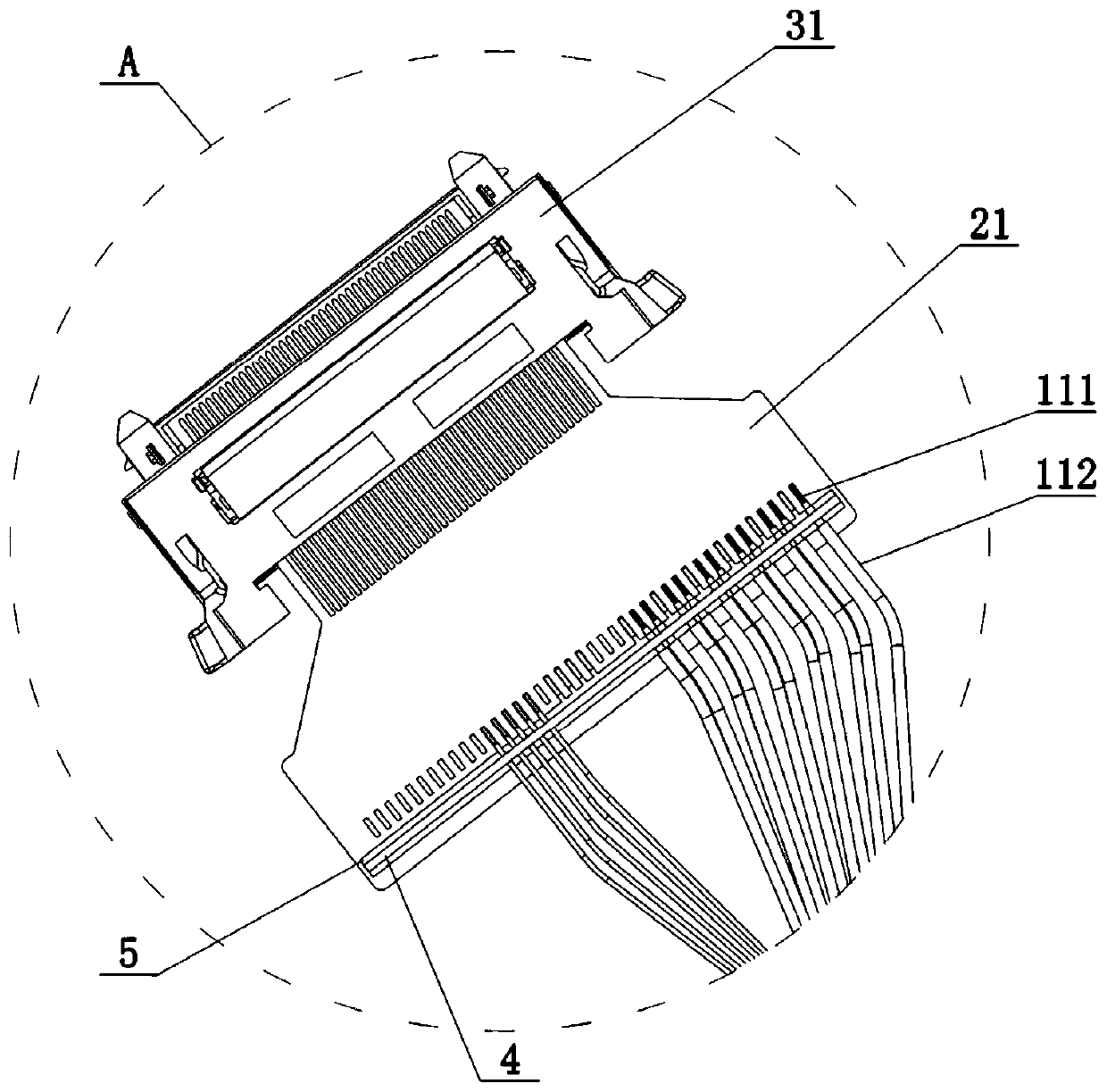

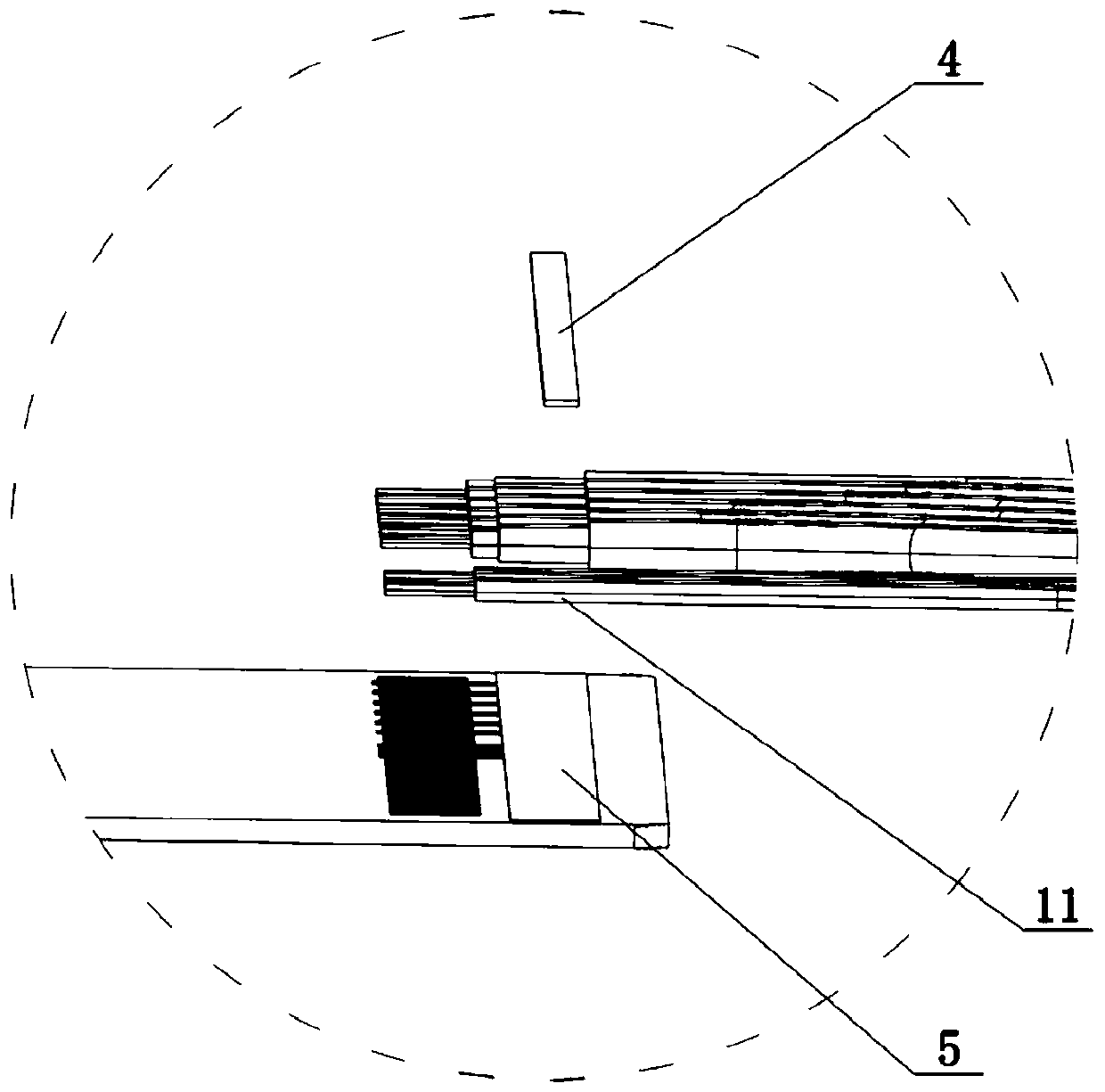

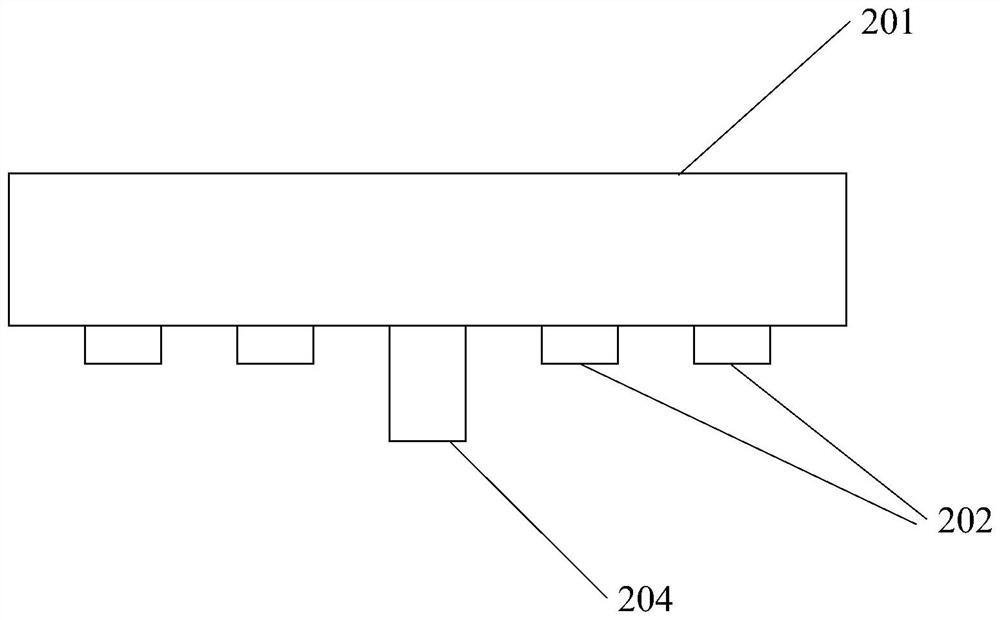

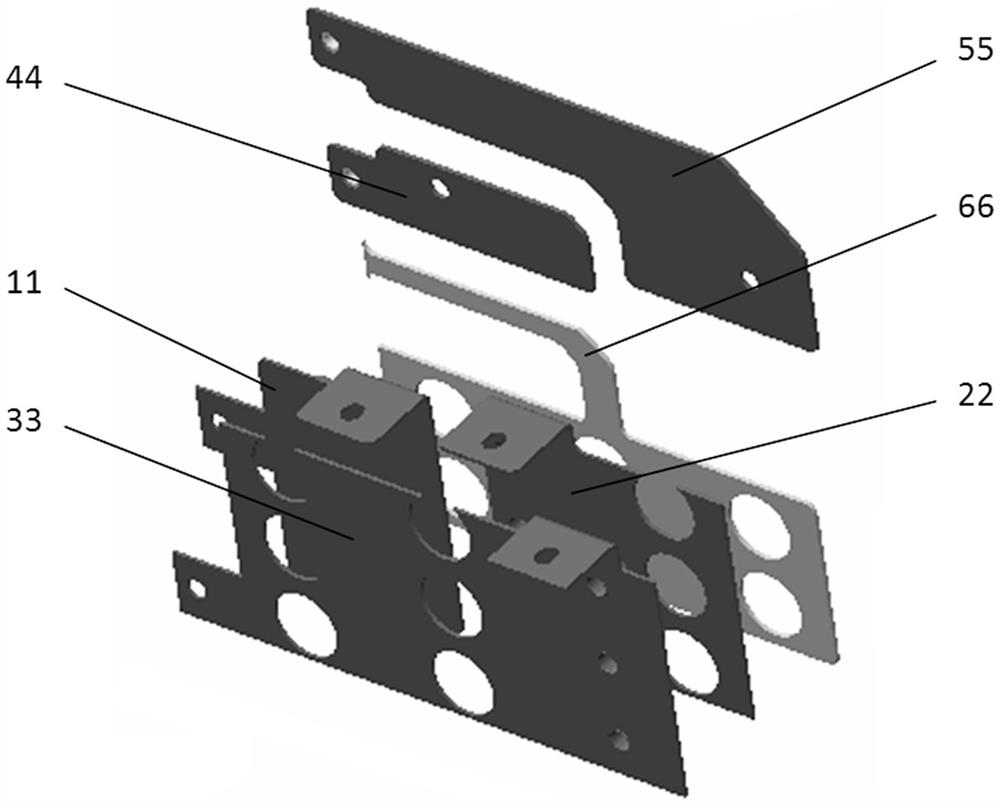

Transmission component

PendingCN110137725ARealize signal transmissionIncrease the designable lengthFixed connectionsCoupling protective earth/shielding arrangementsShielded cableHigh rate

The invention belongs to the technical field of transmission equipment and discloses a transmission component. A cable of the transmission component is connected to a connector through a flexible printed circuit board, and the flexible printed circuit board includes a wire welding end for connecting the cable and a connection end for external end connection. The cable includes a plurality of signal lines. The flexible printed circuit board includes a connection area. The transmission component further includes a grounding piece which is electrically connected to the grounding area and conductive outer layers of the signal lines. In the present invention, the cable and the connector are transferred through the flexible printed circuit board, so that the connector can be adapted to a high-frequency and high-speed cable, the design can be greatly improved compared with an existing transmission component, and the long-distance high-frequency and high-rate signal transmission is achieved.

Owner:SUINING LUXSHARE PRECISION IND CO LTD

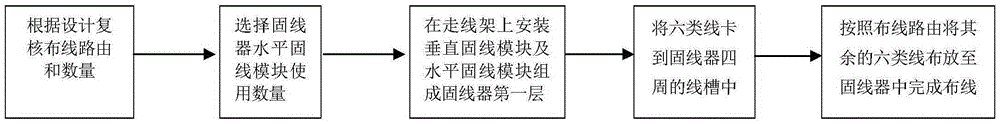

Arranging construction method for six types of wires of IDC machine room

InactiveCN105337222ASimplify construction stepsShorten construction timeApparatus for laying cablesComputer moduleFire safety

The invention discloses an arranging construction method for six types of wires of an IDC machine room. The method comprises the steps that the use number of horizontal wire fixing modules of a wire fixing device is selected, and the wire fixing device is composed of right-angled wire fixing modules, the horizontal wire fixing modules, wiring frame reinforcing members and module connecting sheets; multiple horizontal wire fixing modules are respectively installed in the vertical direction and the horizontal direction of a wiring frame to form the first layer of the wire fixing device; six types of wires are clamped in wire slots around the wire fixing device; and the rest six types of wires are arranged in the wire fixing device according to wire arranging routing so as to complete wire arrangement. The construction steps are simplified and construction time is shortened; future capacity expansion and maintenance are facilitated, and efficiency is enhanced; a cable heat radiation problem is effectively solved, and potential fire safety hazard can be reduced; and the wire fixing device can be randomly assembled to meet the requirements of wire arrangement so that adaptability is high.

Owner:中邮建技术有限公司

A connection device for an electric welding machine

ActiveCN106670692BLabor savingImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFrame basedEngineering

The invention discloses an electric welding machine connecting device which comprises a wall body and a frame base arranged in the wall body. A cavity is arranged at the bottom in the frame base, a slippage part is arranged in the cavity, a control zone is arranged in the outer wall of the left side of the slippage part, a placement groove is formed in the slippage part on the right side of the control zone, a first hollow cavity is formed in the slippage part on the right side of the placement groove, a first baffle is arranged between the first hollow cavity and the placement groove, a second hollow cavity is formed in the slippage part above the first hollow cavity, a first baffle is arranged in the second hollow cavity, a boss is arranged in the second hollow cavity above the first baffle, protruding blocks are arranged at the tops of two sides of the boss, magnets are arranged in the bottoms of the protruding blocks, magnets are arranged in the bottoms of the protruding blocks, electromagnetic coil devices are arranged at the top of the first baffle corresponding to the magnets, first compression springs are arranged between the electromagnetic coil devices and the magnets, and the bottom of the boss penetrates through the first baffle. The electric welding machine connecting device is simple in structure, convenient to operate, small in occupied area and capable of meeting wiring demands of different distances and achieving wire take-up work, and the working efficiency is improved.

Owner:江苏南洋电子有限公司

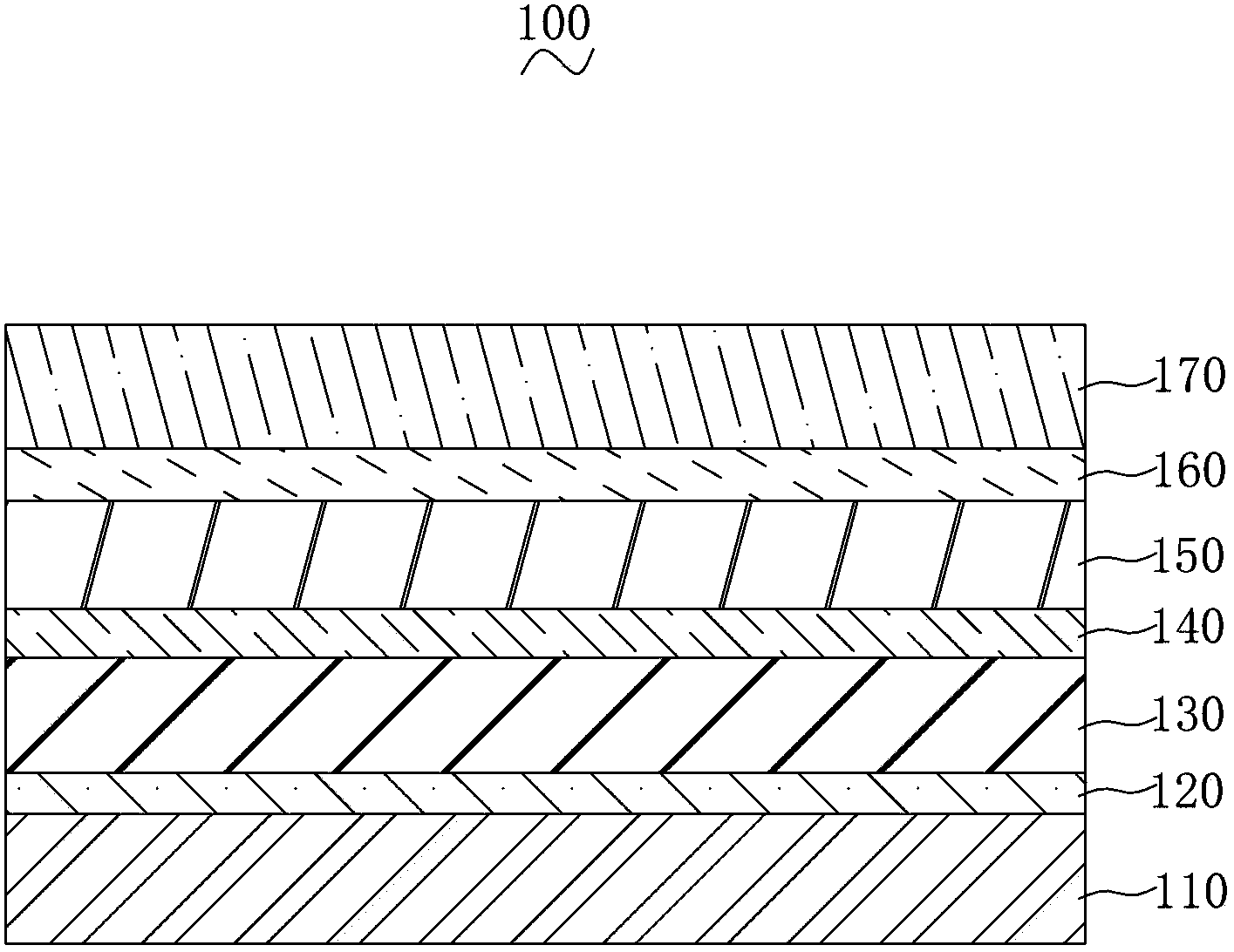

Capacitive touch screen and manufacturing method thereof

ActiveCN103543886BWill not affect workReduce borderInput/output processes for data processingCapacitanceTouchscreen

The invention relates to a capacitive touch screen. The capacitive touch screen comprises panel glass, and the panel glass comprises a touching area and a wiring area placed on the edge of the touching area. The capacitive touch screen further comprises an induction layer, a ground layer, a driving layer, a first circuit and a second circuit, wherein the induction layer, the ground layer and the driving layer are sequentially laminated on the touching area, the first circuit is led out from the induction layer, the second circuit is led out from the driving layer, and the first circuit and the second circuit are arranged in the wiring area of the panel glass in an overlapping mode. By the aid of the ground layer, two capacitors are formed by the driving layer and the ground, and the induction layer and the ground respectively, variations of the two capacitors are both led out in a grounding mode, hence, the capacitors formed by the induction layer and the driving layer are prevented, and when the first circuit and the second circuit are arranged in the wiring area in the overlapping mode, the work of the capacitive touch screen can not be affected; due to the fact that the first circuit and the second circuit are arranged in the overlapping mode, wiring space is greatly reduced, the size of the wiring area is decreased, a frame of the capacitive touch screen is made to be small, and the application of the capacitive touch screen can cater to light and thin large-window design. The invention further provides a manufacturing method of the capacitive touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

A safe connection device for electric welding machine

The invention discloses a safe connecting device for an electric welding machine. The safe connecting device comprises a wall body and a frame base, wherein the frame base is arranged in the wall body; a cavity is formed in the inner bottom of the frame base; a sliding part is arranged in the cavity; a control area is arranged in the outer wall of the left side of the sliding part; a placement groove is formed in the position, on the right side of the control area, of the sliding part; a first hollow cavity is formed in the position, on the right side of the placement groove, of the sliding part; a first baffle is arranged between the first hollow cavity and the placement groove; a second hollow cavity is formed in the position, above the first hollow cavity, of the sliding part; a first baffle is arranged in the second hollow cavity; a boss is arranged in the position, above the first baffle, of the second hollow cavity; and protruding blocks are arranged on the tops of the two sides of the boss; magnets are arranged in the bottoms of the protruding blocks; electromagnetic coil devices are arranged at the positions, corresponding to the magnets, of the top of the first baffle; first pressure springs are arranged between the electromagnetic coil devices and the magnets; and the bottom of the boss penetrates through the first baffle. According to the safe connecting device, the structure is simple, the operation is convenient, the wiring requirements of different distances can be met, and the operation of taking up wires can be automatically realized, the occupied area is small, and the working efficiency is improved.

Owner:枣阳市兴业机械制造有限责任公司

Electric welding machine connecting structure

InactiveCN108237339ALabor savingImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintEngineering

The invention discloses an electric welding machine connecting structure which comprises a wall and a frame base arranged in the wall; a cavity is formed in the frame base; a sliding piece is arrangedin the cavity; a control area is arranged in the outer wall of the left side of the sliding piece; a placing groove is formed in the part, on the right side of the control area, of the sliding piece;a first hollow cavity is formed in the part, on the right side of the placing groove, of the sliding piece; a second baffle is arranged between the first hollow cavity and the placing groove; a second hollow cavity is formed in the part, above the first hollow cavity, of the sliding piece; a first baffle is arranged in the second hollow cavity; a boss is formed in the part, above the first baffle, of the second hollow cavity; raised blocks are arranged at the tops of the two sides of the boss; magnets are arranged in the bottoms of the raised blocks; electromagnetic coil devices are arrangedat the parts, corresponding to the magnets, of the top of the first baffle; a first pressure spring is arranged between each electromagnetic coil device and the corresponding magnet; and the bottom ofthe boss penetrates through the first baffle. The electric welding machine connecting structure is simple in structure and convenient to operate, the wiring requirements at different distances can bemet, winding work is automatically realized, the floor area is small and the working efficiency is improved.

Owner:温岭市兴庆机械设备有限公司

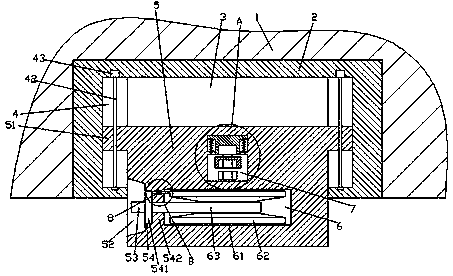

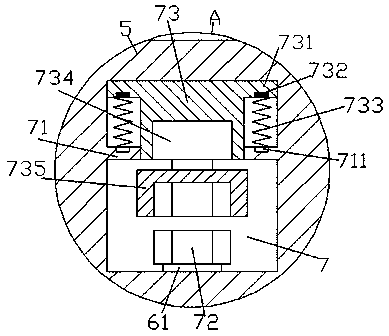

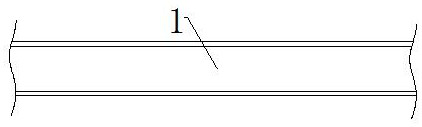

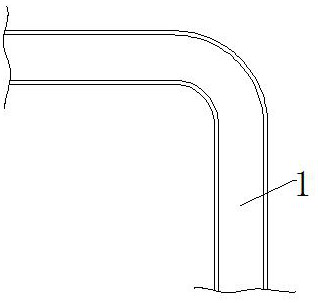

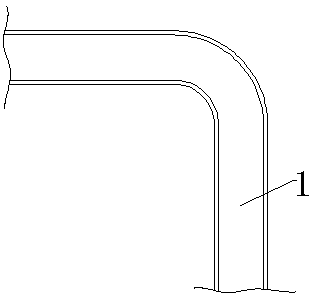

A bendable wiring trough

ActiveCN109842074BImprove wiring efficiencyEasy to operateElectrical apparatusCompressive resistanceSupport plane

The invention discloses a bendable wire duct which comprises an outer tank and a base plate. The two sides of the base plate are clamped to the inner edge of the outer tank, the outer tank is bar-shaped and includes an ach cross section, arc bracing frames are distributed uniformly in the outer tank, and the plane where the arc bracing frames are positioned is vertical to the length direction of the outer tank; and the base plate comprises a middle rack and multiple side racks. Both the floor and the outer tank are arranged into bendable structures respectively, the wire duct can be bent directly during wiring, it is not required to cross-cut the wire duct and guide and fix the wire duct via an external elbow, and thus, the wiring efficiency is improved, and operation is convenient and safe; and the arc bracing frames are arranged in the outer tank, the surface of the tank is supported while the outer tank is bent, the outer tank is prevented from fracture in the bending process, the tensile intensity is improved, and the wire duct is widly suitable for wiring in the wall, ceiling and floor.

Owner:SHANGHAI HUIJUE NETWORK COMM EQUIP

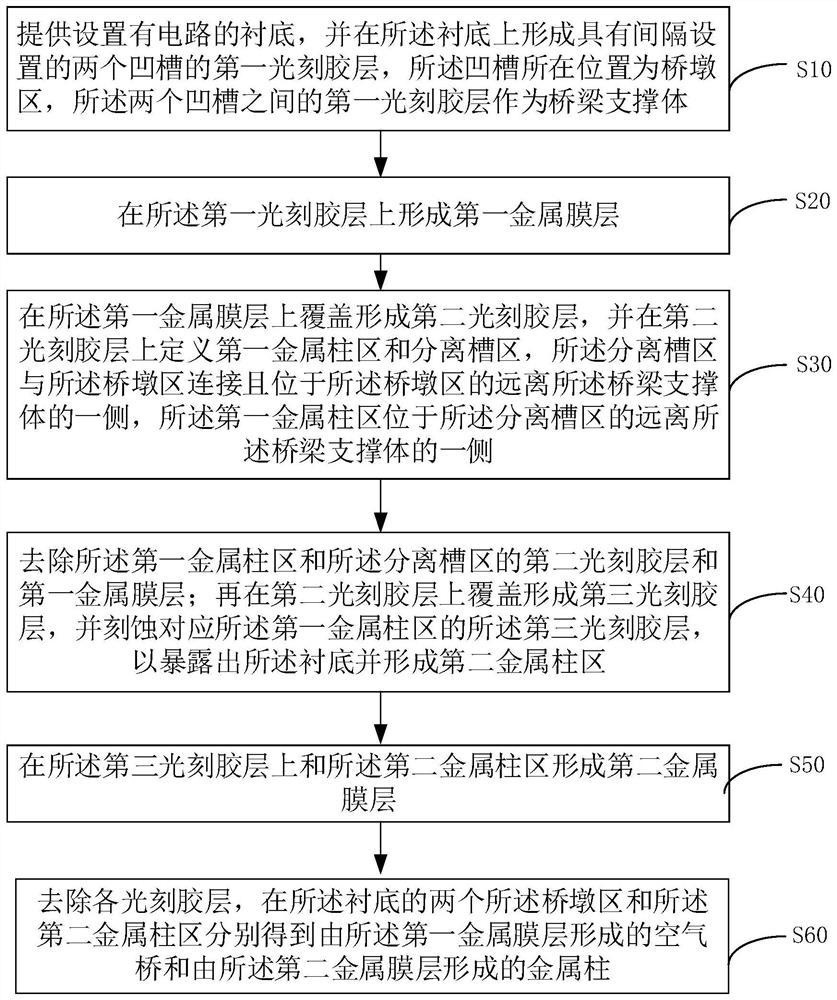

Superconducting quantum chip and preparation method and application thereof

PendingCN114171669AIncrease the number of qubitsMeet wiring needsSuperconductor detailsDissimilar materials junction devicesPhysicsPhotoresist

The invention relates to the technical field of micro-nano processing, in particular to a superconducting quantum chip and a preparation method and application thereof. The preparation method of the superconducting quantum chip comprises the following steps that a substrate provided with a circuit is provided, a first photoresist layer with two grooves arranged in a spaced mode is formed on the substrate, and the portion, between the two grooves, of the first photoresist layer serves as a bridge supporting body; forming a first metal film layer on the first photoresist layer; forming a second photoresist layer on the first metal film layer in a covering manner, and defining a first metal column region and a separation groove region on the second photoresist layer; removing the second photoresist layer and the first metal film layer in the first metal column region and the separation groove region; covering the second photoresist layer to form a third photoresist layer, and etching to expose the substrate and form a second metal column region; forming a second metal film layer on the third photoresist layer and the second metal column region; and removing each photoresist layer.

Owner:北京量子信息科学研究院

Bendable wire duct

The invention discloses a bendable wire duct which comprises an outer tank and a base plate. The two sides of the base plate are clamped to the inner edge of the outer tank, the outer tank is bar-shaped and includes an ach cross section, arc bracing frames are distributed uniformly in the outer tank, and the plane where the arc bracing frames are positioned is vertical to the length direction of the outer tank; and the base plate comprises a middle rack and multiple side racks. Both the floor and the outer tank are arranged into bendable structures respectively, the wire duct can be bent directly during wiring, it is not required to cross-cut the wire duct and guide and fix the wire duct via an external elbow, and thus, the wiring efficiency is improved, and operation is convenient and safe; and the arc bracing frames are arranged in the outer tank, the surface of the tank is supported while the outer tank is bent, the outer tank is prevented from fracture in the bending process, the tensile intensity is improved, and the wire duct is widly suitable for wiring in the wall, ceiling and floor.

Owner:SHANGHAI HUIJUE NETWORK COMM EQUIP

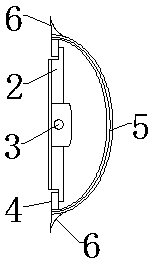

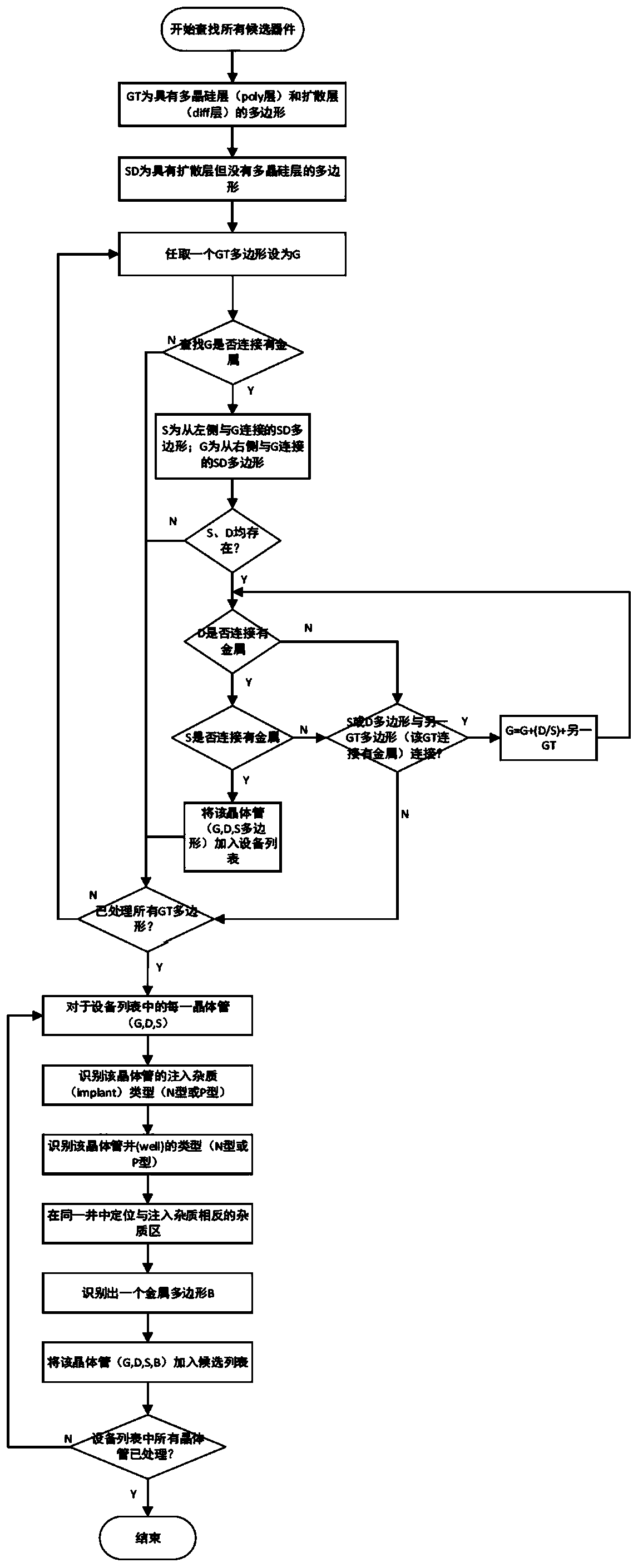

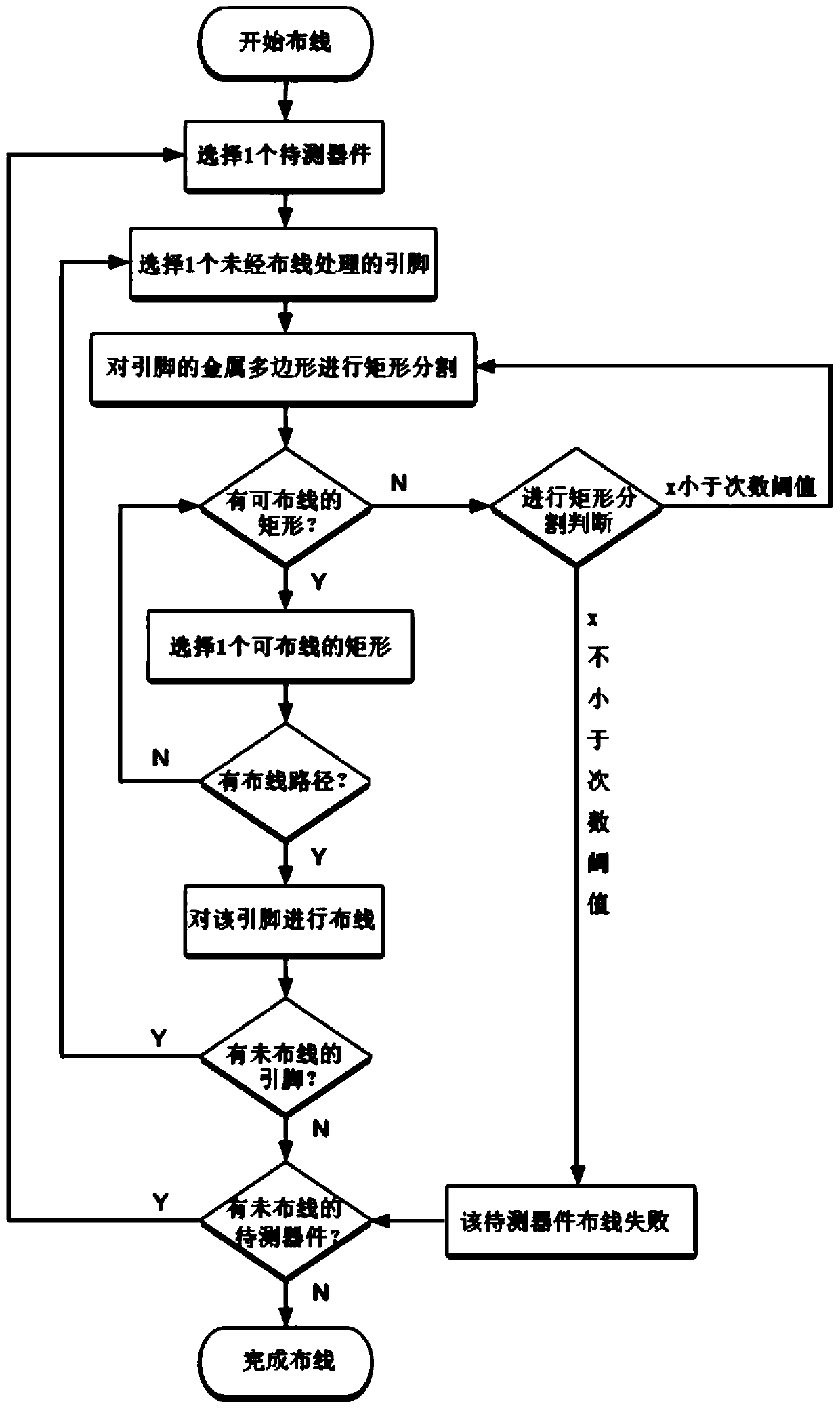

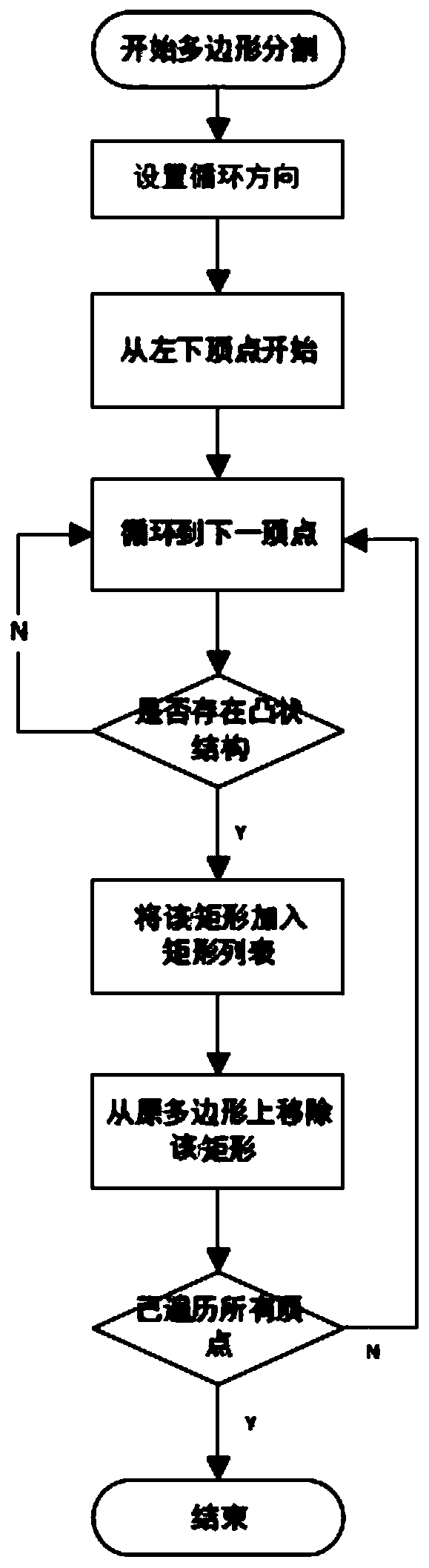

Method for layout wiring of transistors in to-be-tested array one by one

PendingCN111444668AGuarantee the quality of wiringShorten the timeComputer aided designSpecial data processing applicationsProcess engineeringEngineering

The invention relates to a method for layout wiring of transistors in a to-be-tested array one by one. The method comprises a preprocessing process and a wiring process. The method includes: determining that the candidate device corresponds to the metal frame through a preprocessing process and determining the position of the candidate device; and wiring each pin of the to-be-tested device throughthe wiring process. According to the invention, the wiring quality is ensured and the time is saved while the to-be-tested devices are processed and wired one by one.

Owner:SEMITRONIX

Electronic connector

PendingCN113381254ARealize the branching functionMeet wiring needsSecuring/insulating coupling contact membersEngineeringElectrical connector

Owner:SHANGHAI UPUN ELECTRIC GRP

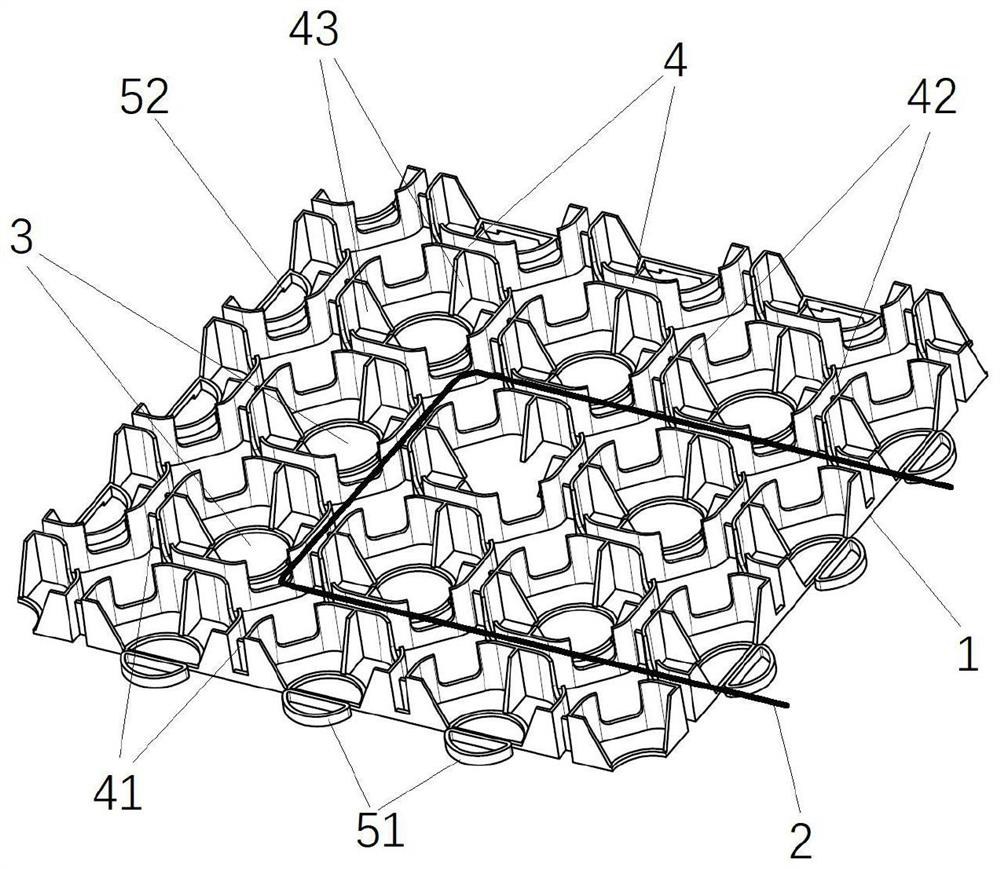

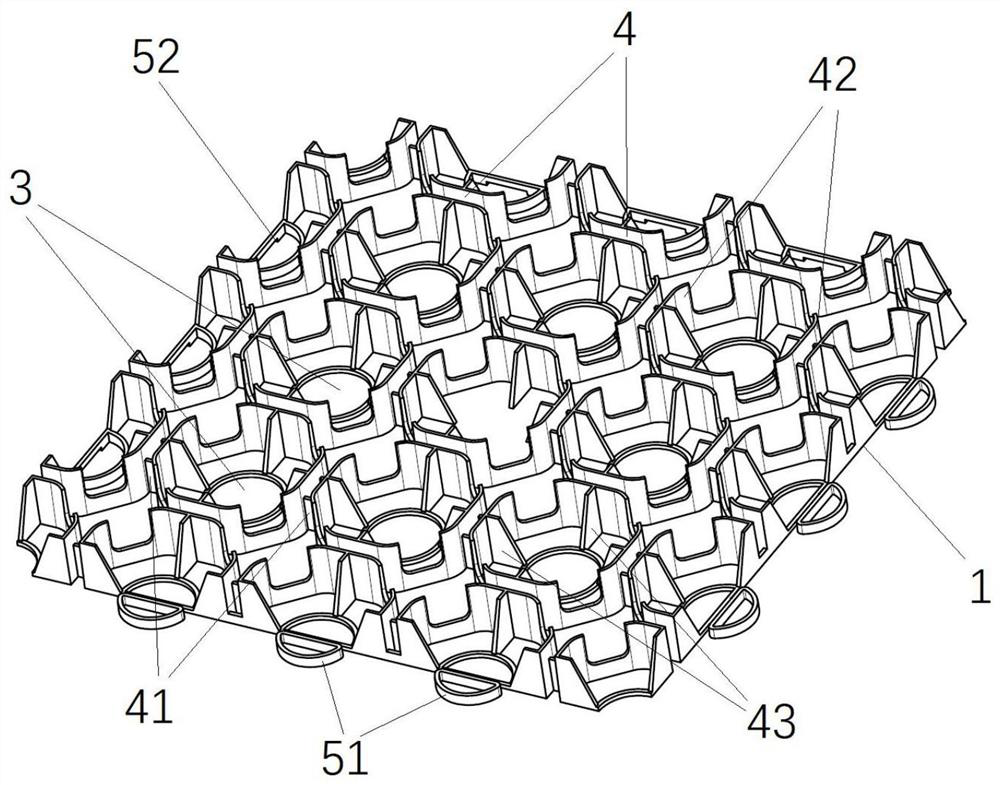

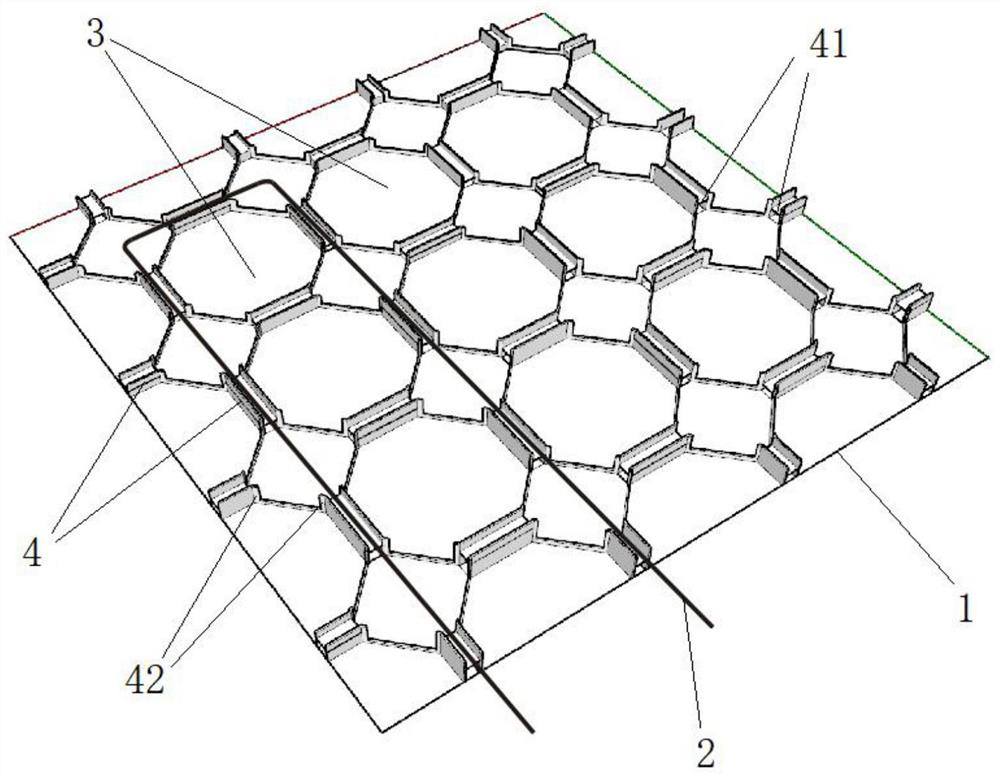

Wiring board, wiring method, electric heating assembly, ceramic tile and floor heating laying method

PendingCN113923804AImprove the heating effectReduce energy consumptionHeating fuelCovering/liningsEngineeringHeat transfer efficiency

The invention discloses a wiring board, a wiring method, an electric heating assembly, a ceramic tile and a floor heating laying method which are used for laying the electric heating wires for floor heating. The wiring board comprises a body, the body is provided with a plurality of pivot parts arranged in a distributed manner, and each pivot part is provided with one or more channel parts used for clamping the electric heating wires. Each channel part is also provided with a supporting piece which is configured to support the electric heating wires, so that a preset distance is formed between the electric heating wires and the bottom of the body. According to the present invention, the supporting piece is arranged to support the electric heating wires, so that the electric heating wires can be tightly attached to the floor tiles, energy consumption is reduced in the heating process, the heat transfer efficiency is greatly improved, and the heating effect of floor heating is better.

Owner:苏州康碳地暖科技有限公司

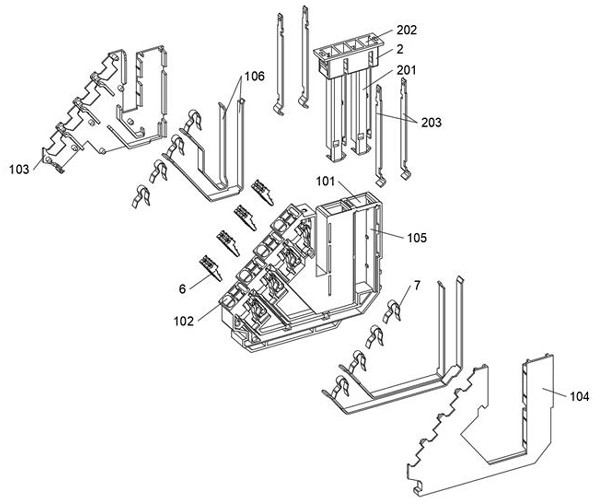

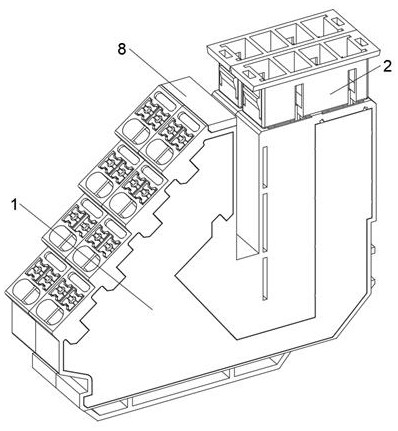

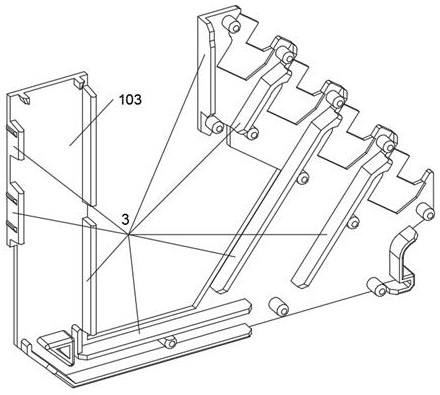

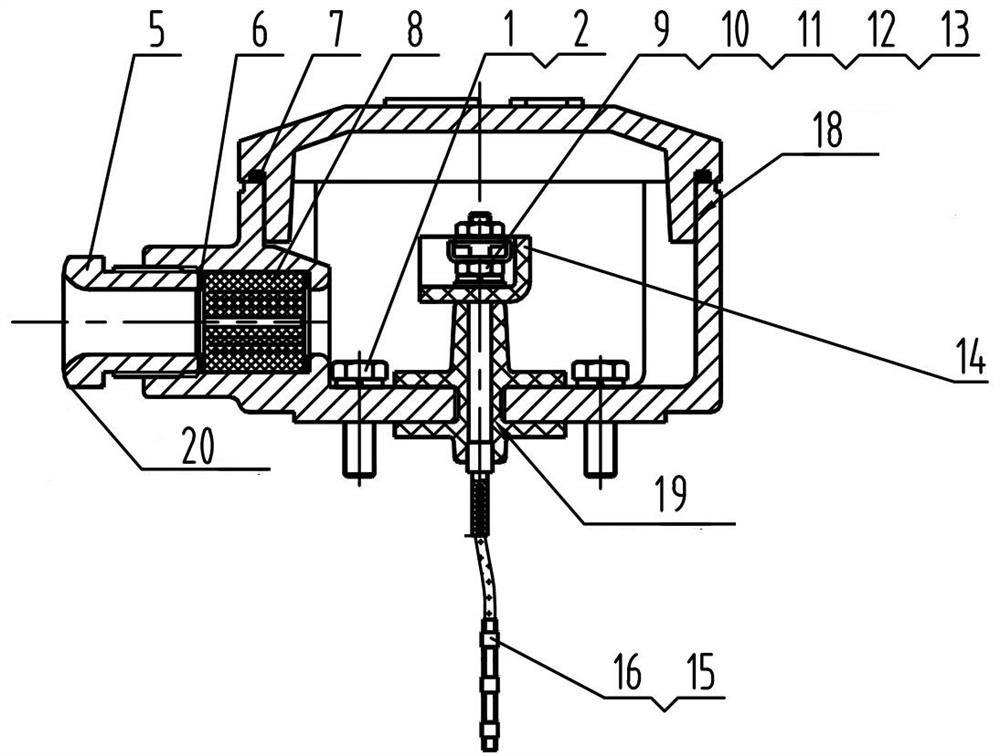

Auxiliary heating junction box of YBX4 high-efficiency explosion-proof three-phase asynchronous motor

PendingCN113691067AReduce volumeIncrease electrical clearanceAssociation with grounding devicesSupports/enclosures/casingsProcess engineeringThree phase asynchronous motor

The invention discloses an auxiliary heating junction box of a YBX4 high-efficiency explosion-proof three-phase asynchronous motor, which belongs to the technical field of explosion-proof motor junction boxes, and comprises a junction box seat, a junction box bucket connected with one side of the junction box seat, and a junction box cover connected with the upper part of the junction box seat, a wiring component is arranged in the junction box seat, and the wiring component comprises a terminal sleeve integrated with the junction box seat in a die-casting manner, a wiring mounting plate arranged at the upper part of the terminal sleeve, and a wiring bolt penetrating through the terminal sleeve and the wiring mounting plate. The auxiliary heating junction box solves the technical problems of large size and large occupied space of the conventional auxiliary junction box of the explosion-proof motor, is compact in structure, small in size, high in electrical performance and capable of separating strong and weak electricity, greatly reduces the cost, can meet the wiring requirements of various models, and provides wiring convenience for a heater of a YBX4 high-efficiency explosion-proof three-phase asynchronous motor; the wiring bolt is convenient to install and replace, and the wiring efficiency is remarkably improved.

Owner:南阳防爆电气研究所有限公司

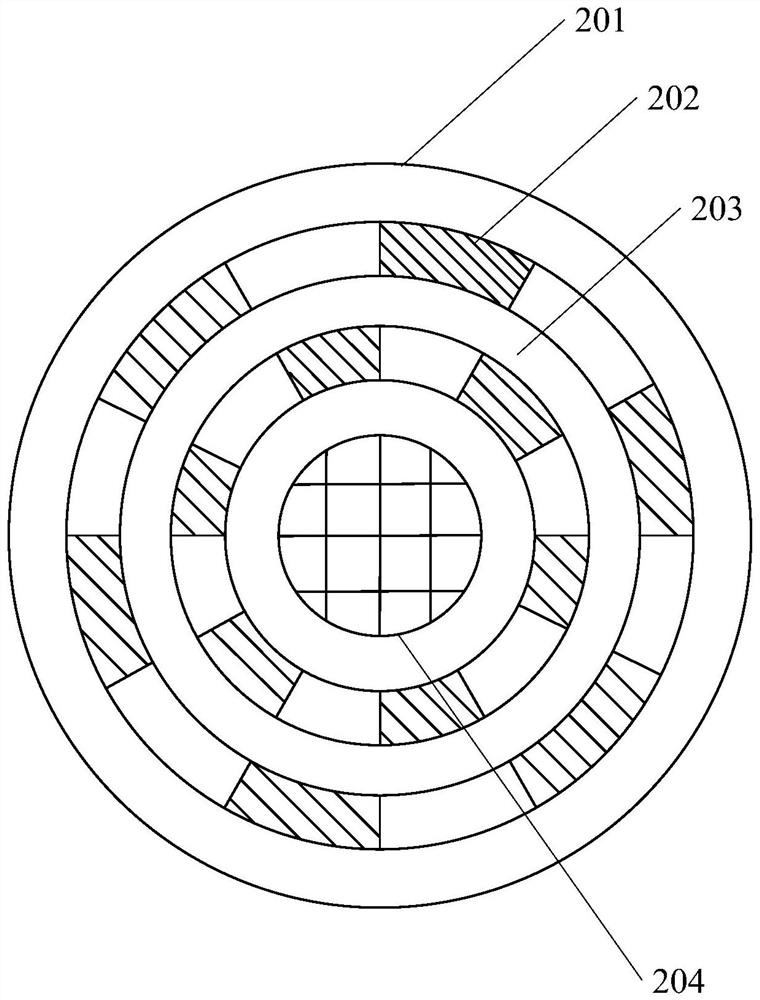

Convenient-to-use resistor

ActiveCN113363028AEasy to fixMeet wiring needsResistor terminals/electrodesResistor mounting/supportingEngineeringStructural engineering

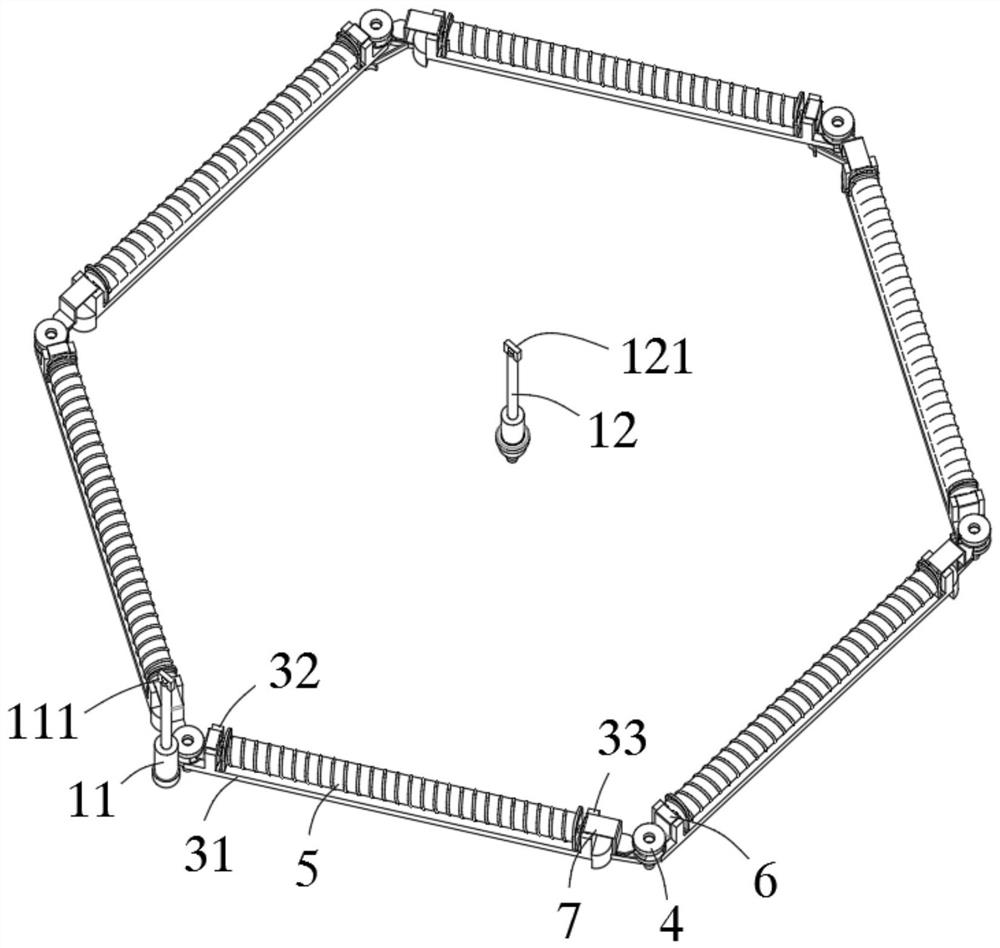

The invention discloses a convenient-to-use resistor. The resistor comprises a box body, a plurality of rotating shafts are uniformly distributed on the inner circumference of the box body, the bottom end of each rotating shaft is rotatably arranged on the box body, and a ceramic base is fixed at the top end of each rotating shaft; one side of each ceramic base is connected with a mounting base, the plurality of mounting bases are uniformly distributed along the circumference, and a connecting assembly is connected between every two adjacent mounting bases along the circumference; each mounting base is composed of a supporting plate, a first vertical plate and a second vertical plate, and the first vertical plate and the second vertical plate are perpendicularly fixed to the two sides of the top of the supporting plate; a resistor body is arranged in each mounting base, and connecting ends are arranged at the two ends of each resistor body respectively; and each connecting assembly comprises a first connecting plate and a second connecting plate, and the first connecting plate and the second connecting plate are in contact with the connecting ends of the two circumferentially adjacent resistor bodies respectively. Different resistance values can be conveniently accessed, and maintenance and replacement are convenient.

Owner:安徽功率电气有限公司

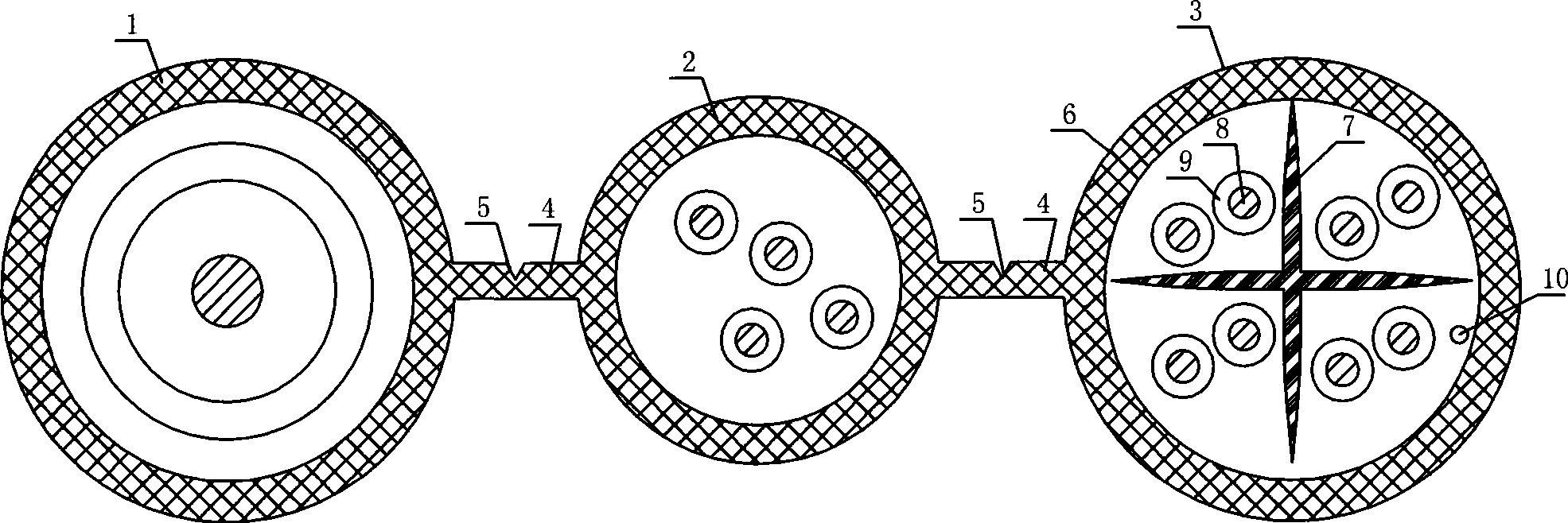

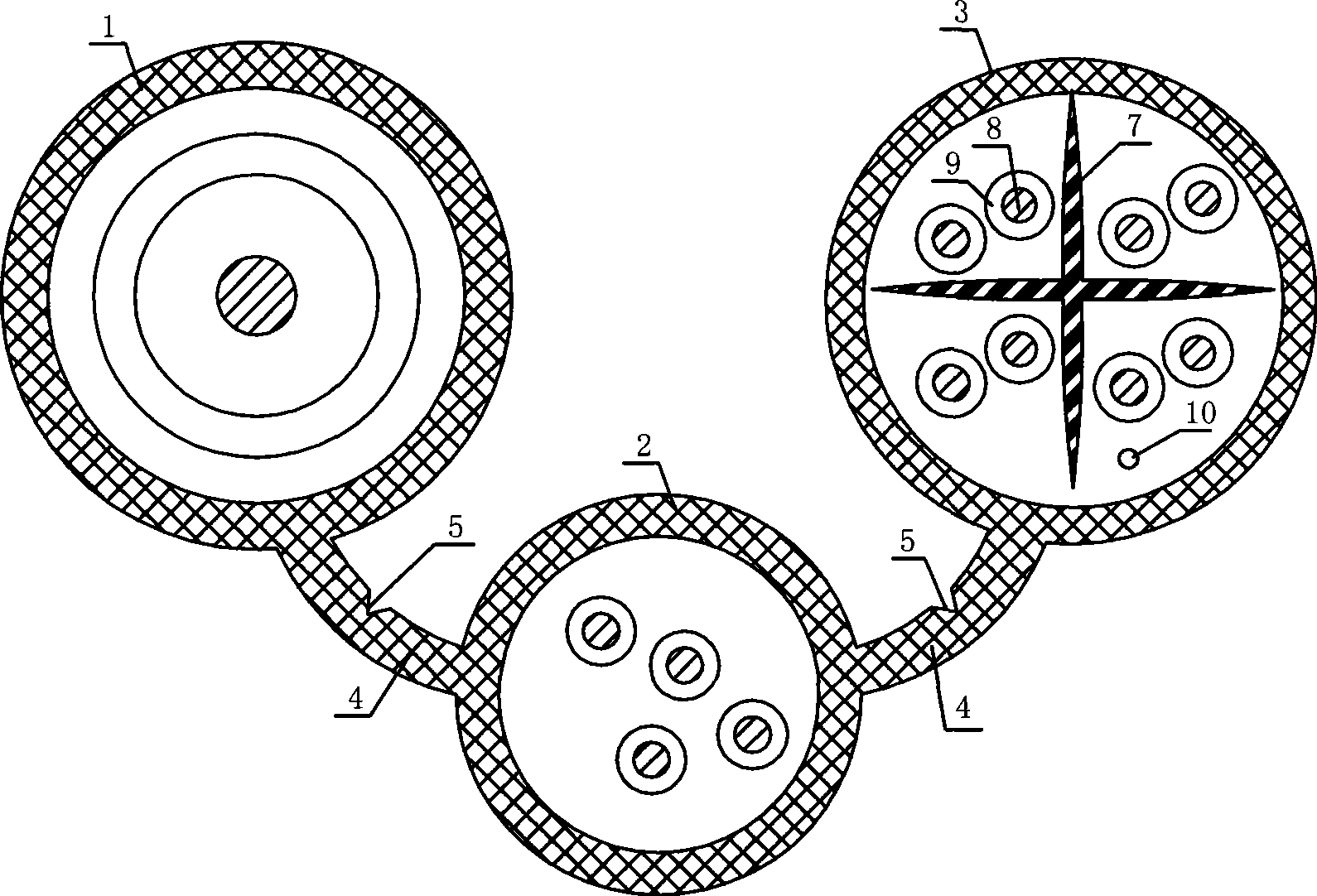

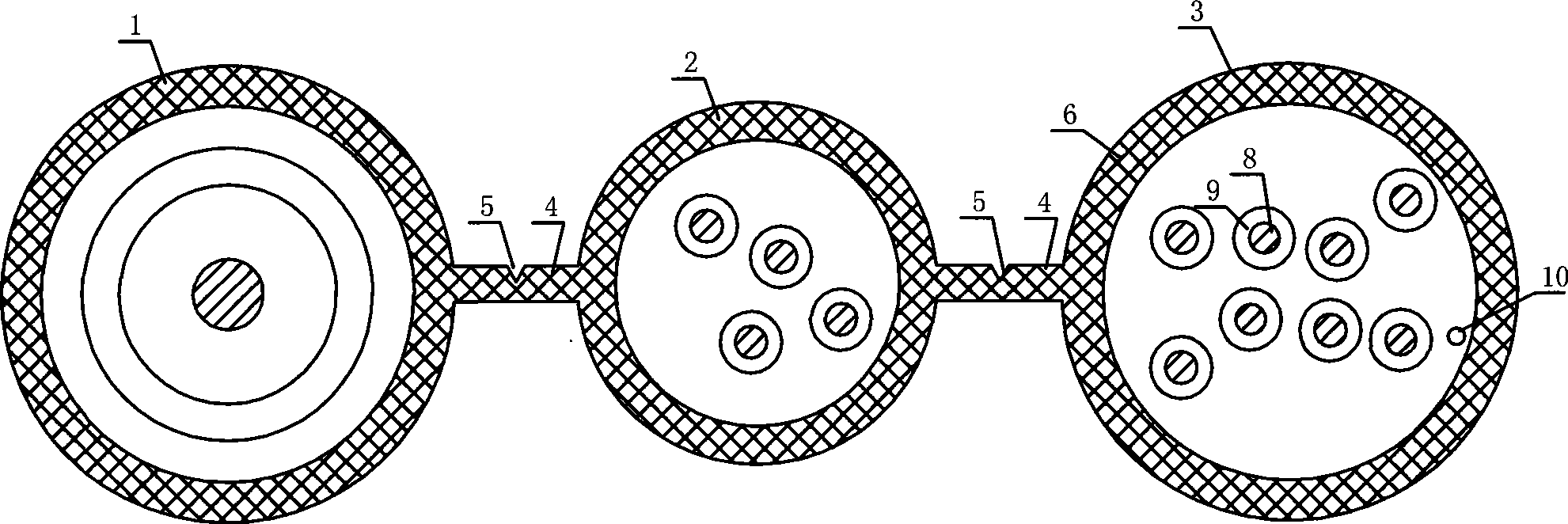

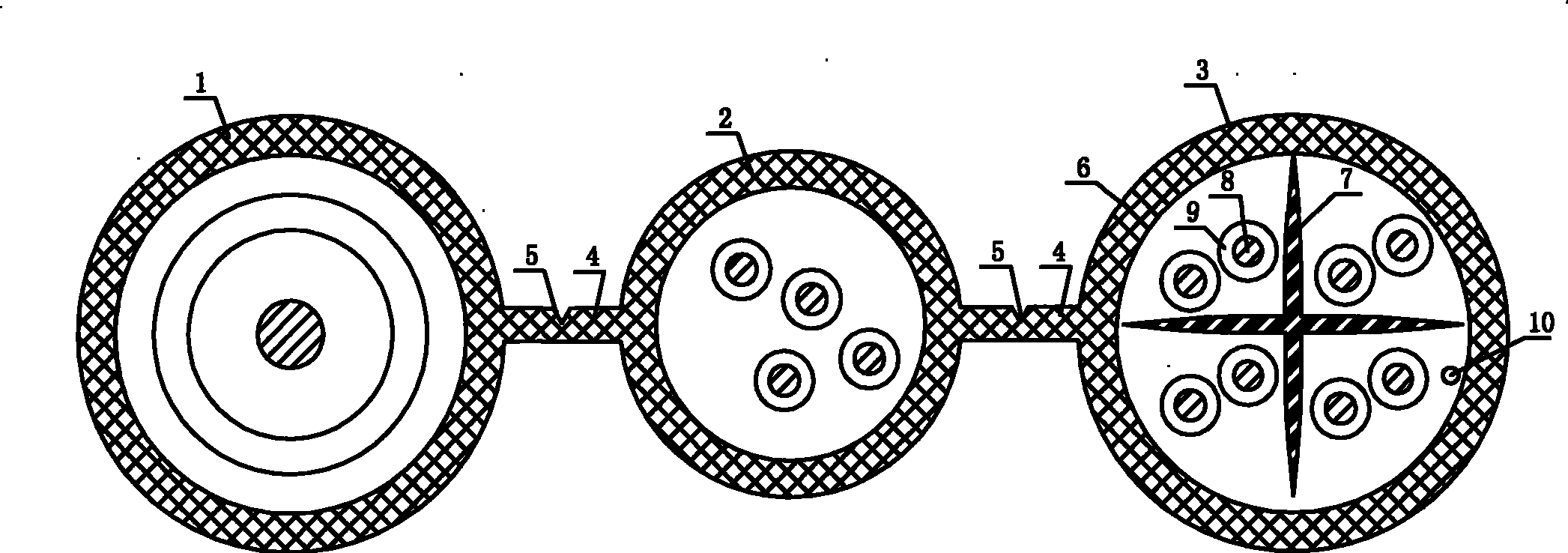

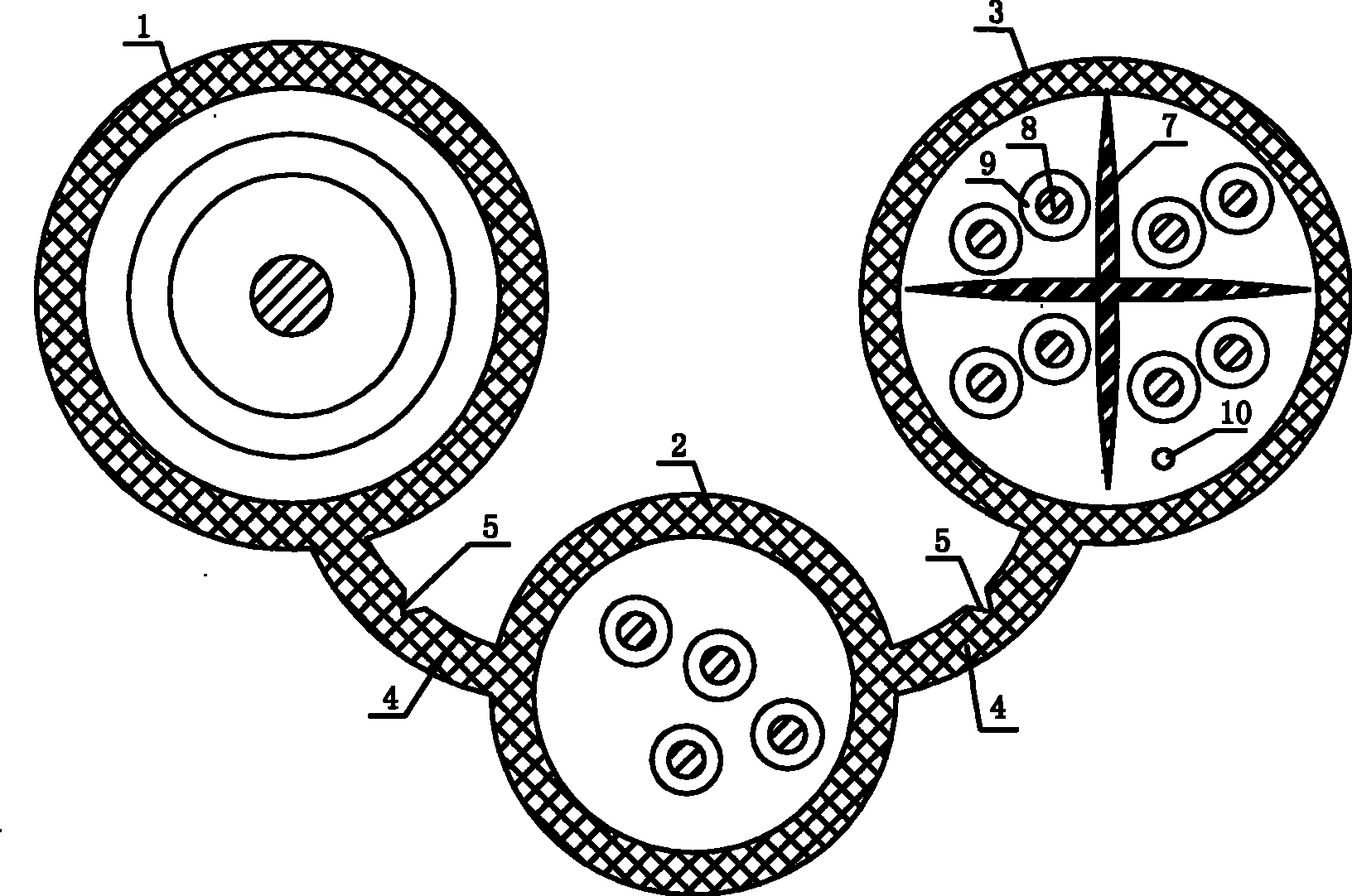

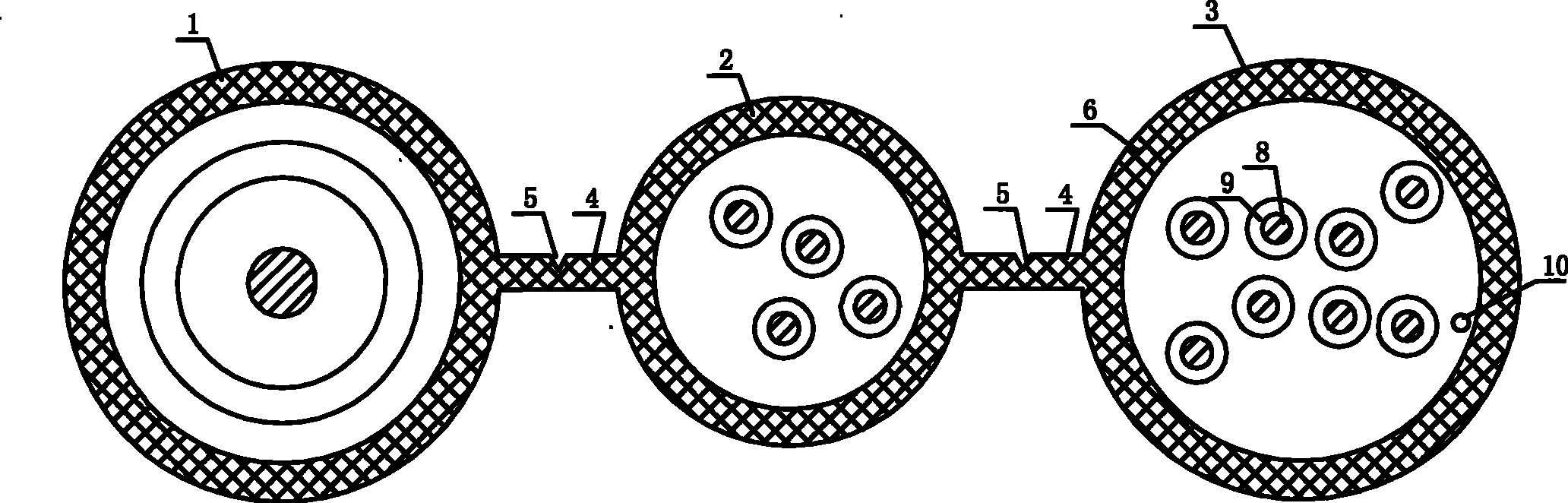

Three-assembling combination cable

ActiveCN101373647APerformance unchangedIntegrity guaranteedFlat/ribbon cablesInsulated conductorsCoaxial cableWhole body

The invention relates to a cable, particularly to a multipurpose combination cable. A three-strand combination cable comprises a digital cable, a telephone wire and a coaxial cable. The digital cable, the telephone wire and the coaxial cable comprise respective outer protection sleeves. Connection parts are arranged among the three outer protective sleeves and connect the digital cable, the telephone wire and the coaxial cable as a whole body. The cable of the invention has the characteristics that: the cable construction and installation is more convenient, the application function of the cable is enhanced, the tensile property thereof is improved, and the shape thereof can be changed according to different construction occasions, so that the cable is suitable for various occasions.

Owner:ZHEJIANG ZHAOLONG CABLE

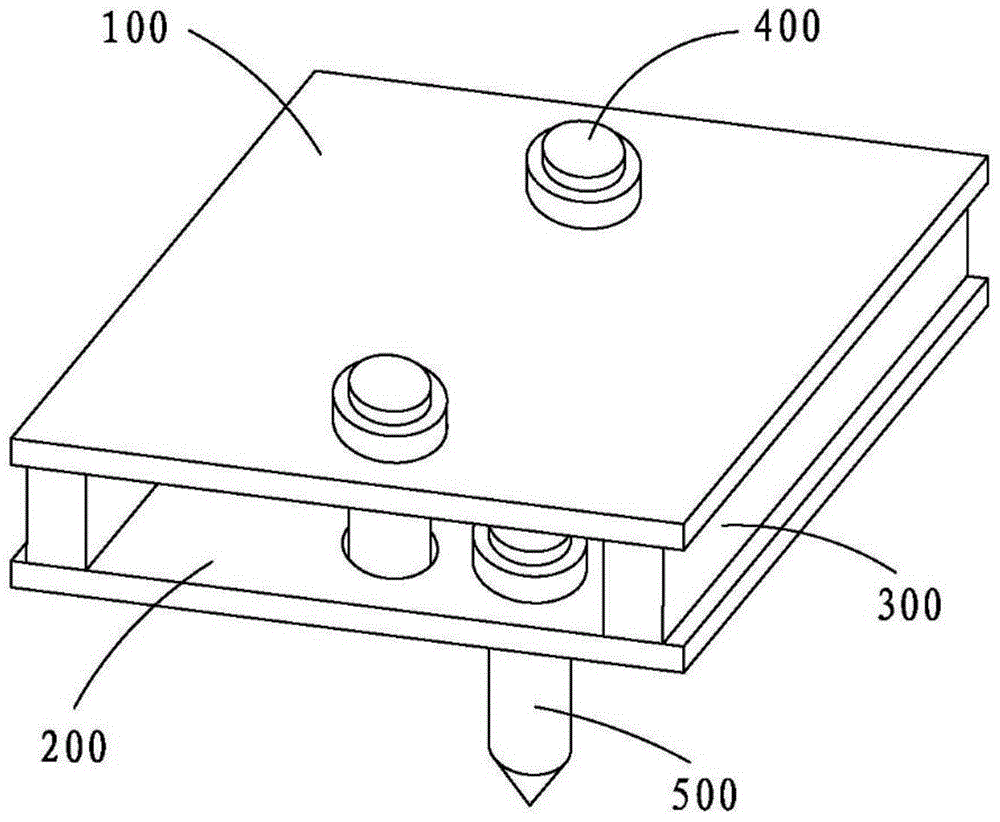

Signal pin set device

ActiveCN114498198AIncrease shielding levelMeet wiring needsCoupling device detailsElectrical conductorSignal on

The invention discloses a signal pin set device which is composed of a device body and a plurality of conductor materials arranged on the device body, and the arrangement positions of the conductor materials are flexibly arranged according to the size and the shape of an available space instead of an existing mode that the conductor materials are fixedly arranged on one conductor material in a linear mode. Therefore, the signal shielding level is improved while the reasonable utilization of the layout space is ensured; each conductor material is provided with a signal pin and a grounding pin, so that the signal wiring requirement is met; insulating materials are filled among the conductor materials, so that signal isolation among the conductor materials is realized. One or more signal pins can be arranged on one conductor material according to the requirement of signals on the shielding effect and different signal types, for example, one high-speed signal pin independently occupies one conductor material, and comprehensive isolation of high-speed signals is guaranteed.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

High-voltage wiring harness arrangement structure for new energy cargo truck

The invention discloses a high-voltage wiring harness arrangement structure for a new energy cargo truck, and relates to the field of new energy vehicles. The arrangement structure comprises a telescopic bottom plate and a wire bunching device, wherein a supporting block I is fixedly arranged at one end of the telescopic bottom plate, and a supporting block II is fixedly arranged at the other endof the telescopic bottom plate; a butt joint which is fixed on the supporting block I through a fixing seat is arranged on the supporting block I; a rotating seat is fixedly arranged on the supportingblock II; a connecting seat is rotationally connected to the rotating seat; a connecting plug is fixedly arranged on the connecting seat; the butt joint and the connecting plug are correspondingly arranged; and the wire bunching device comprises a cylindrical elastic wire bunching tube. According to the arrangement structure, due to the fact that the wire bunching device can be assembled to the telescopic bottom plate, the wire bunching devices can be fixedly assembled, the number of the wire bunching devices can be flexibly selected according to the number of wires, the wire bunching devicescan be mutually assembled and assembled to the telescopic bottom plate, so that the use is very flexible and changeable, the wiring requirements of various conditions can be met, and the wiring efficiency is greatly improved.

Owner:懿福新能源科技有限公司

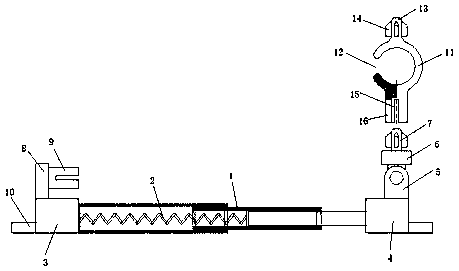

Adjustable high-efficiency cable peeling device and working method thereof

ActiveCN105680378AFast PeelingHigh strengthApparatus for removing/armouring cablesUltimate tensile strengthElectrical and Electronics engineering

The invention belongs to the technical field of circuit inspection and construction application accessories, and particularly discloses an adjustable high-efficiency cable peeling device. The adjustable high-efficiency cable peeling device consists of a positioning movement assembly and a rotary peeling assembly. The adjustable high-efficiency cable peeling device and a working method thereof disclosed by the invention have the beneficial effects that the design structure is reasonable, the strength is high, the weight is light, a cable at a high attitude can be peeled quickly, the peeling quality meets a cabling requirement, a peeling opening does not need to be trimmed again artificially, and meanwhile, the cables with a plurality of pipe diameters can be peeled by an adjustable peeling knife, and the application range is wide.

Owner:XINGHUA YONGSHENG POWER EQUIP

Three-assembling combination cable

ActiveCN101373647BPerformance unchangedIntegrity guaranteedFlat/ribbon cablesInsulated conductorsCoaxial cableWhole body

The invention relates to a cable, particularly to a multipurpose combination cable. A three-strand combination cable comprises a digital cable, a telephone wire and a coaxial cable. The digital cable, the telephone wire and the coaxial cable comprise respective outer protection sleeves. Connection parts are arranged among the three outer protective sleeves and connect the digital cable, the telephone wire and the coaxial cable as a whole body. The cable of the invention has the characteristics that: the cable construction and installation is more convenient, the application function of the cable is enhanced, the tensile property thereof is improved, and the shape thereof can be changed according to different construction occasions, so that the cable is suitable for various occasions.

Owner:ZHEJIANG ZHAOLONG CABLE

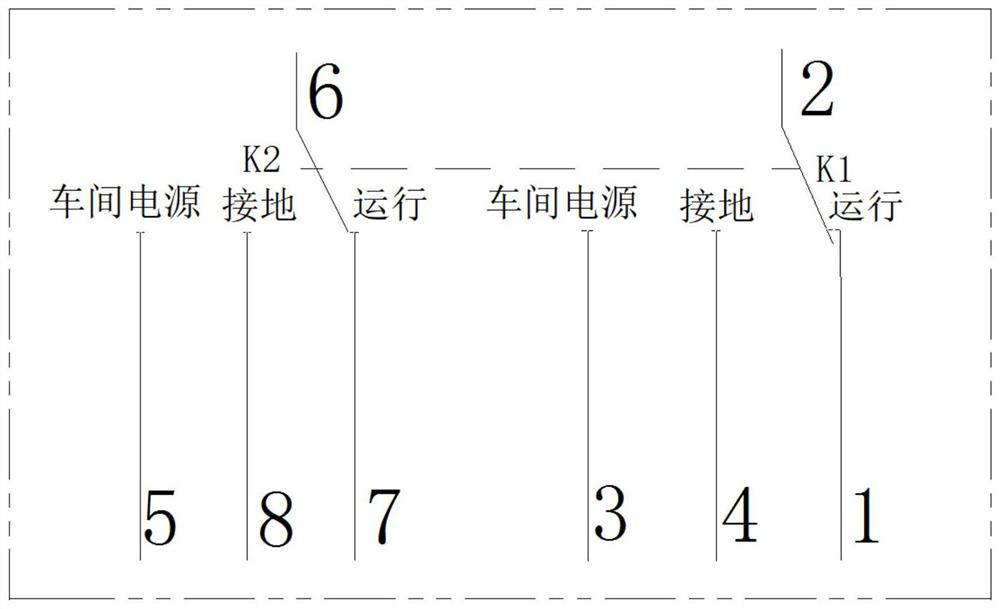

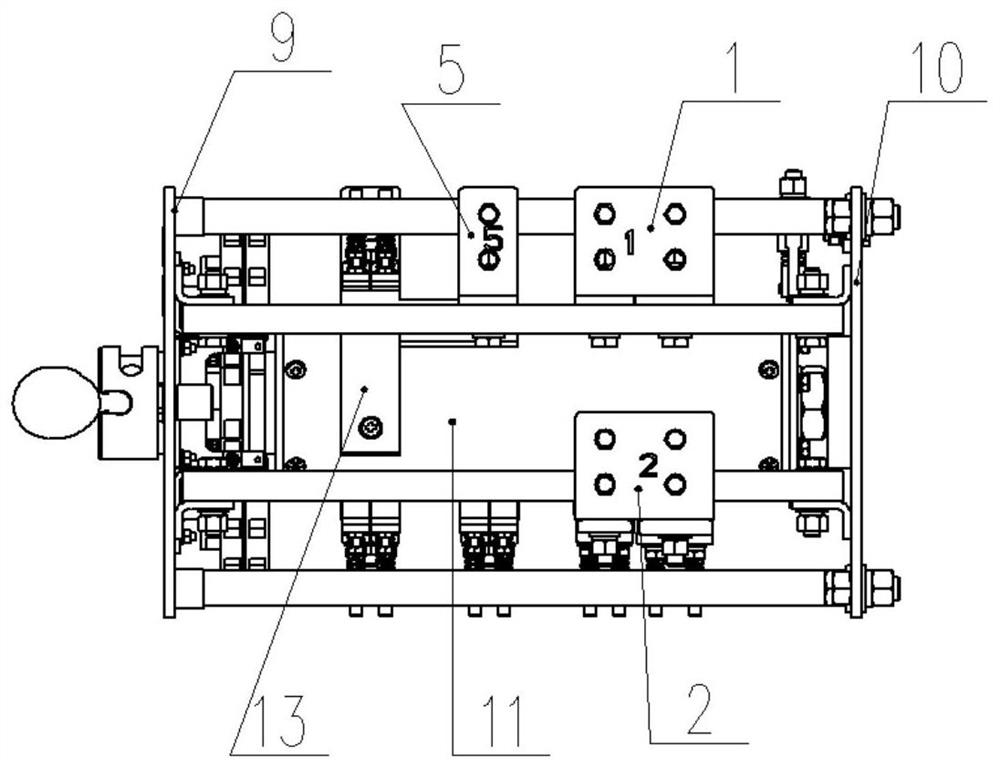

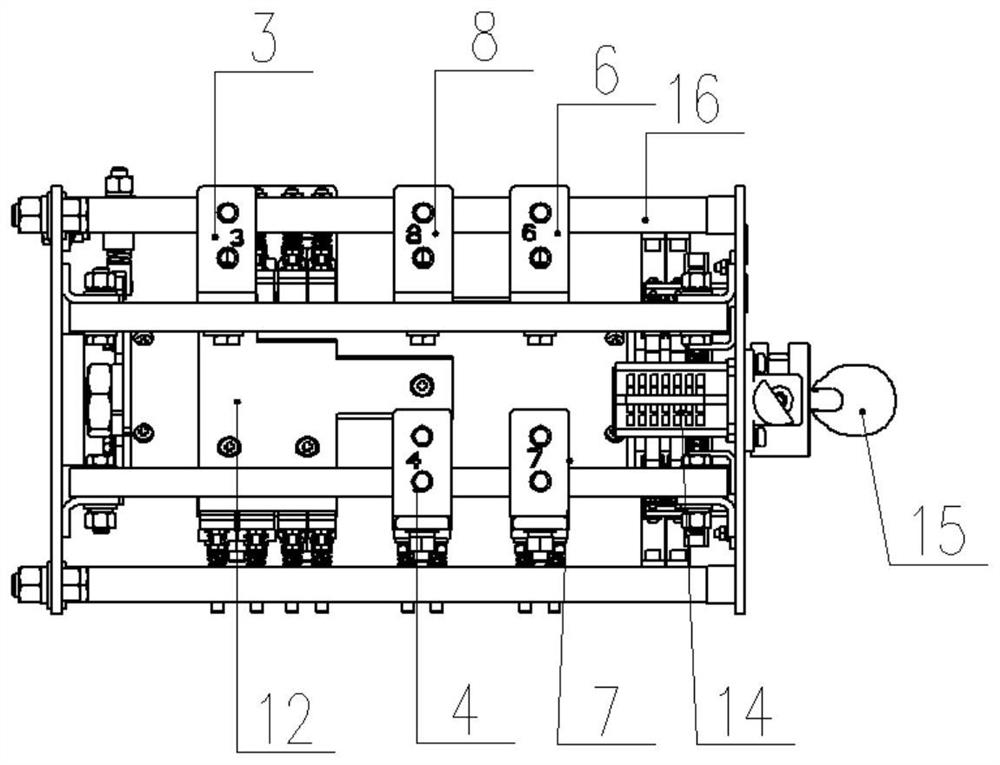

Conversion drum type three-position switch device and control method and system thereof

ActiveCN112885637AMeet wiring needsFlexible connectionAir-break switch detailsControl systemHemt circuits

The invention discloses a conversion drum type three-position switch device. The conversion drum type three-position switch device comprises a first contact, a second contact, a third contact, a fourth contact, a fifth contact, a sixth contact, a seventh contact and an eighth contact which are located on a plurality of connection rods. A first switch and a second switch which are located on a middle conversion drum are included. The first switch and the second switch are two electrically isolated contact fingers respectively and coaxially rotate along with the middle conversion drum. The first switch and the second switch which rotate coaxially and are electrically isolated are designed on the middle conversion drum, along with the state change of the middle conversion drum, the first switch and the second switch are connected with different contacts, and a circuit structure which rotates coaxially and is electrically isolated is arranged in the switch device. Wiring requirements of different circuits can be met without additionally arranging wires or copper bars according to the wiring requirements, and other circuits can be more flexibly and externally connected. The invention also correspondingly discloses a control method and a control system of the conversion drum type three-position switch.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

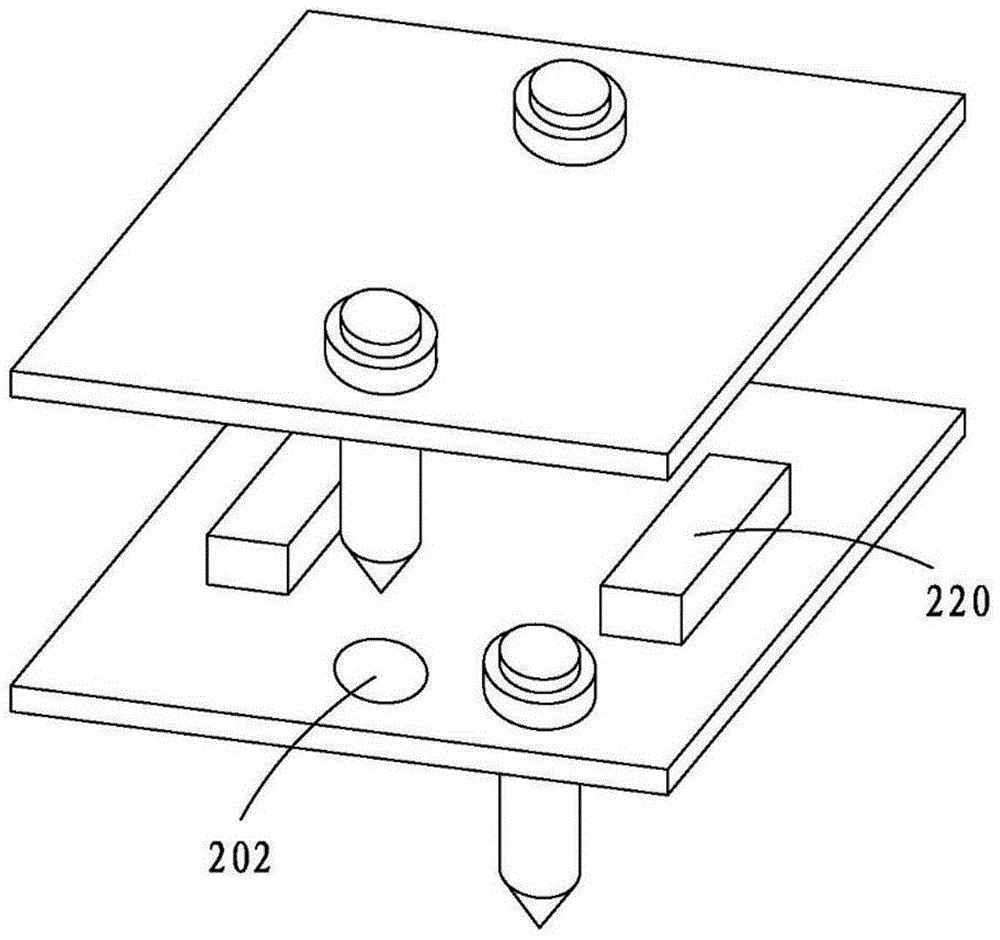

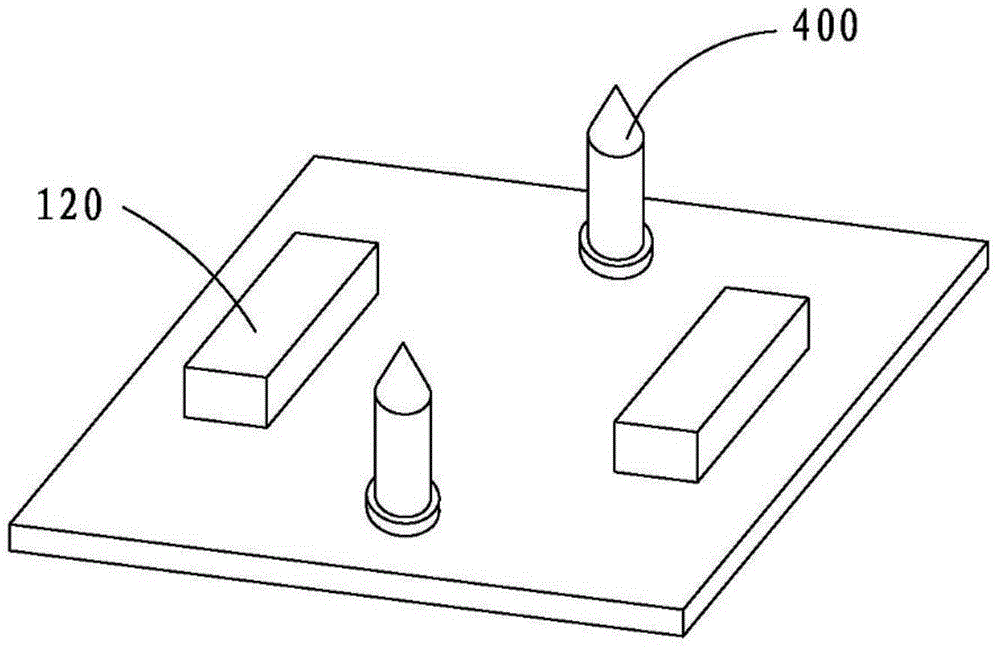

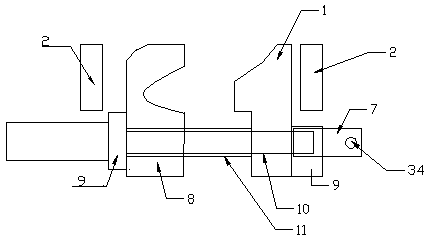

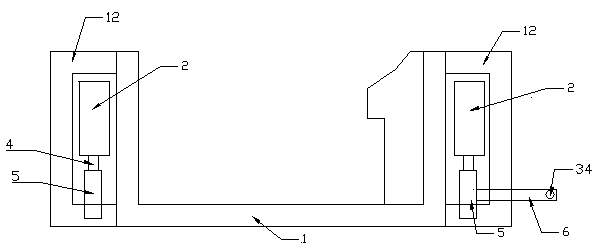

Interconnected back plate

InactiveCN106168840ARealize interconnectionAchieve electrical connectionDigital processing power distributionData switching networksInterconnectionComputer engineering

The invention discloses an interconnected back plate which comprises a first back plate unit and a second back plate unit. The first back plate unit and the second back plate unit are overlaid. The surface, facing the second back plate unit, of the first back plate unit is provided with a plurality of first plugged connection portions. The surface, facing the first back plate unit, of the second back plate unit is provided with a plurality of second plugged connection portions matched with the first plugged connection portions. The first plugged connection portions and the second plugged connection portions are in plugged connection, and therefore the first back plate unit and the second back plate unit are fixedly connected. According to the interconnected back plate, due to the fact that the first plugged connection portions are arranged on the first back plate unit and the second plugged connection portions are arranged on the second back plate unit, interconnection between the first back plate unit and the second back plate unit is easily achieved, then, a circuit board installed on the first back plate unit is electrically connected with a circuit board installed on the second back plate unit, the wiring area is effectively increased, and therefore more wiring requirements are met.

Owner:ZTE CORP

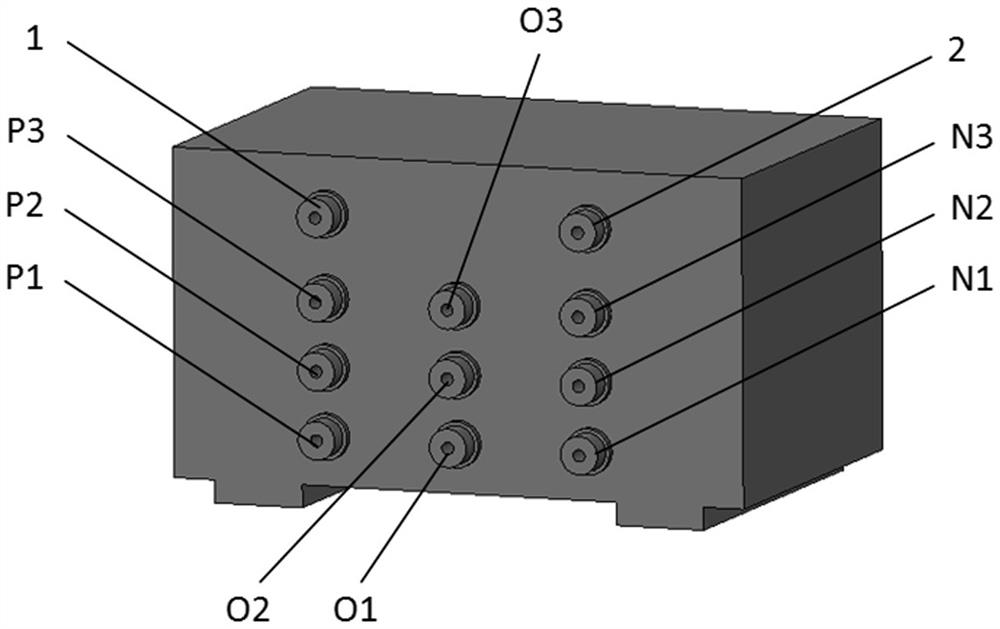

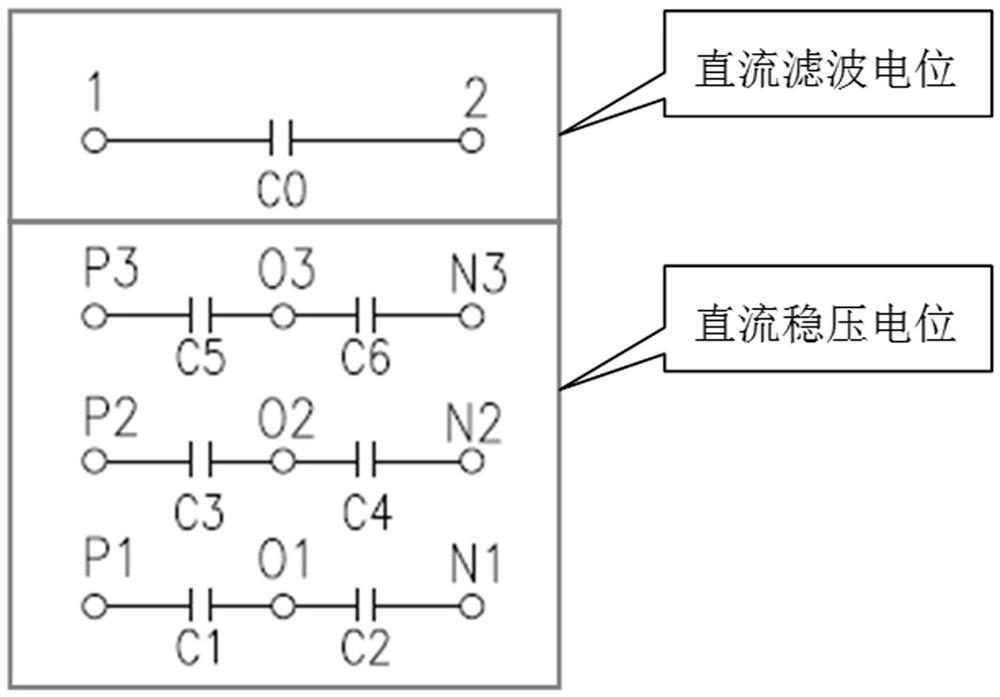

A composite busbar for charger integrated capacitor

ActiveCN112713787BMeet wiring needsMeet the needs of external short circuitConversion constructional detailsCapacitanceBusbar

The invention relates to an integrated capacitor composite busbar, in particular to a composite busbar used for an integrated capacitor of a charger. The utility model relates to a composite busbar used for integrating capacitors of a charger. There are 5 layers of busbars stacked from top to bottom, consisting of U busbar, V busbar, W busbar, positive busbar and negative busbar. It is electrically connected to the P-phase, O-phase, N-phase, 1-phase and 2-phase of the integrated capacitor respectively through self-locking nuts. The invention provides a composite busbar design for the integrated capacitor of the charger, which consists of 5 layers of busbars. It is safe and effective to use the DC filter positive electrode 1, DC filter negative electrode 2 and 3 groups of the integrated capacitor for the potential of DC voltage regulation. P, O, N are separated, which has the advantages of high integration and high space utilization. At the same time, the installation is convenient and the technology is mature. Insulation is used in the middle of each potential, and the electrical performance is reliable and the failure rate is low.

Owner:CRRC YONGJI ELECTRIC CO LTD

An adjustable cable stripper and its working method

ActiveCN105680378BReasonable design structureHigh strengthApparatus for removing/armouring cablesUltimate tensile strengthElectrical and Electronics engineering

The invention belongs to the technical field of circuit inspection and construction application accessories, and particularly discloses an adjustable high-efficiency cable peeling device. The adjustable high-efficiency cable peeling device consists of a positioning movement assembly and a rotary peeling assembly. The adjustable high-efficiency cable peeling device and a working method thereof disclosed by the invention have the beneficial effects that the design structure is reasonable, the strength is high, the weight is light, a cable at a high attitude can be peeled quickly, the peeling quality meets a cabling requirement, a peeling opening does not need to be trimmed again artificially, and meanwhile, the cables with a plurality of pipe diameters can be peeled by an adjustable peeling knife, and the application range is wide.

Owner:XINGHUA YONGSHENG POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com