An adjustable cable stripper and its working method

A working method and stripper technology, which is applied in the direction of cable installation, cable installation device, equipment for dismantling/armored cables, etc., can solve the problems of inability to strip the cable, difficult stripping of the skin material, low stripping efficiency, etc., to achieve The effect of light weight and wide application range, reasonable design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

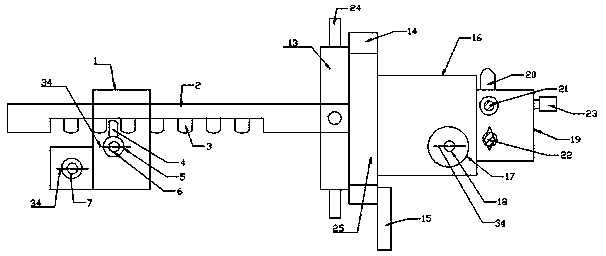

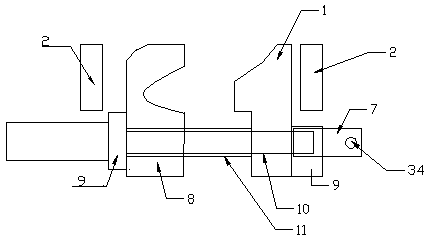

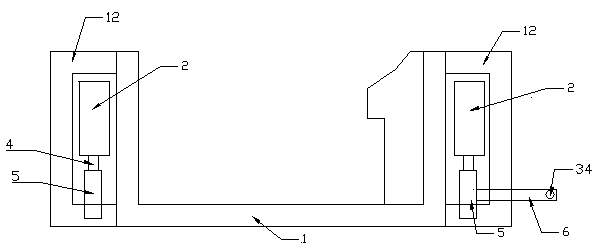

[0026] In the work of the present invention, the first step uses the rotation adjustment handle 15 to align the positions of the notches 29 of the fixed coil 13 and the moving coil 14, and then uses the positioning adjustment rod 7, the sliding adjustment rod 6 and the cutting adjustment rod 18 to respectively set the limit position. The relative position of block 8 and slider 1 is opened, the slider 1 and slide rail 2 are adjusted to a suitable position, the relative position of cutting positioning block 16 and cutting limit block 28 is opened, and finally the peeling knife is used to adjust the tightness of the screw 21 and the peeling knife respectively. Knife angle adjustment screw rod 22 and peeling knife positioning rod 23 adjust the suitable angle of peeling knife 20. In the second step, first, the overall structure is snapped into the cable to be peeled by using the notch 29 on the fixed coil 13 and the moving coil 14 and adjusted to the position to be peeled, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com