Capacitive touch screen and manufacturing method thereof

A capacitive touch screen, capacitive technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problem of large frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to solve the problem of large frame of the existing capacitive touch screen, a capacitive touch screen with small frame and a preparation method thereof are provided. Further elaboration will be given below through specific embodiments and accompanying drawings.

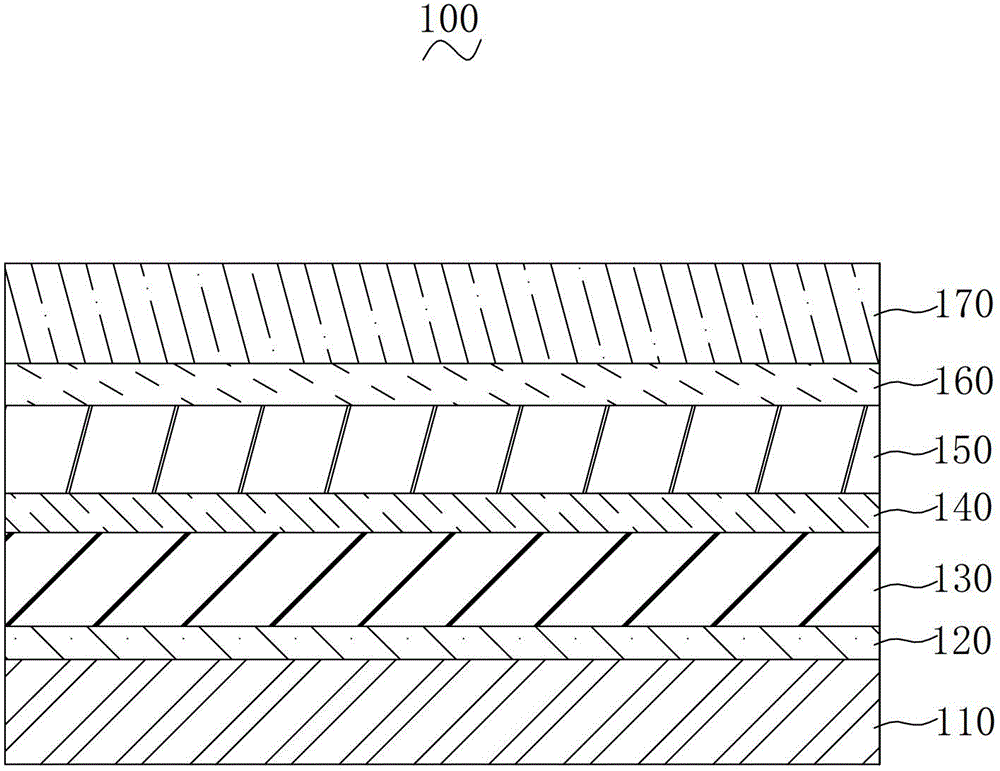

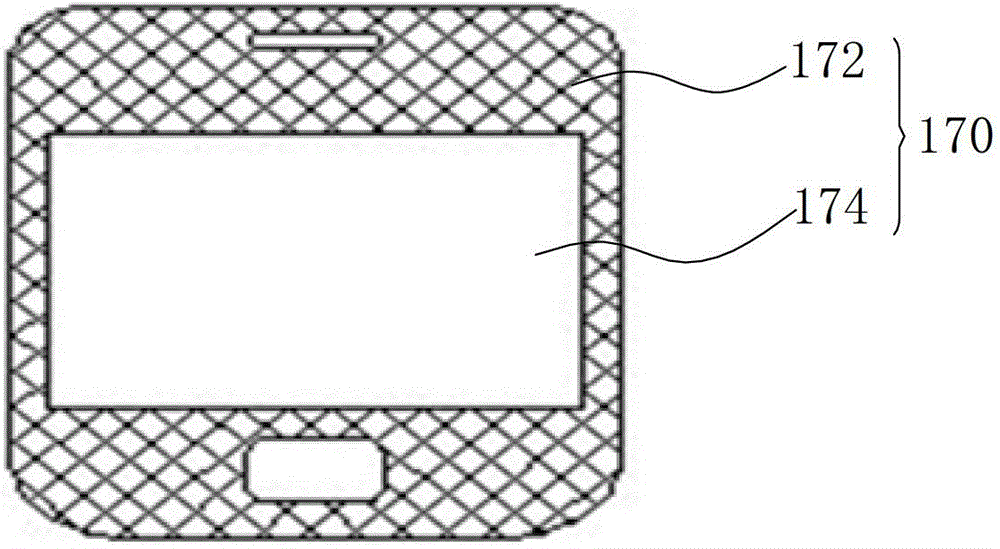

[0027] see figure 1 , a capacitive touch screen 100 according to one embodiment includes a driving layer 110 , a first adhesive layer 120 , a ground layer 130 , a second adhesive layer 140 , a sensing layer 150 , a third adhesive layer 160 and a panel glass 170 stacked in sequence.

[0028] The driving layer 110 is a driving electrode of the capacitive touch screen 100 . When the capacitive touch screen 100 is working, the drive layer 110 sends out low voltage and high frequency signals.

[0029] The driving layer 110 includes a transparent base film (not shown in the figure) and a conductive layer (not shown in the figure) stacked on the transparent base film. Considering both the conductivity and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com