Superconducting quantum chip and preparation method and application thereof

A superconducting quantum and chip technology, applied in the manufacture/processing of superconducting devices, superconducting devices, superconducting components, etc., can solve the problems of limiting the development of superconducting quantum chips and the inability to increase the number of qubits in quantum chips, etc. The effect of increasing the number of qubits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

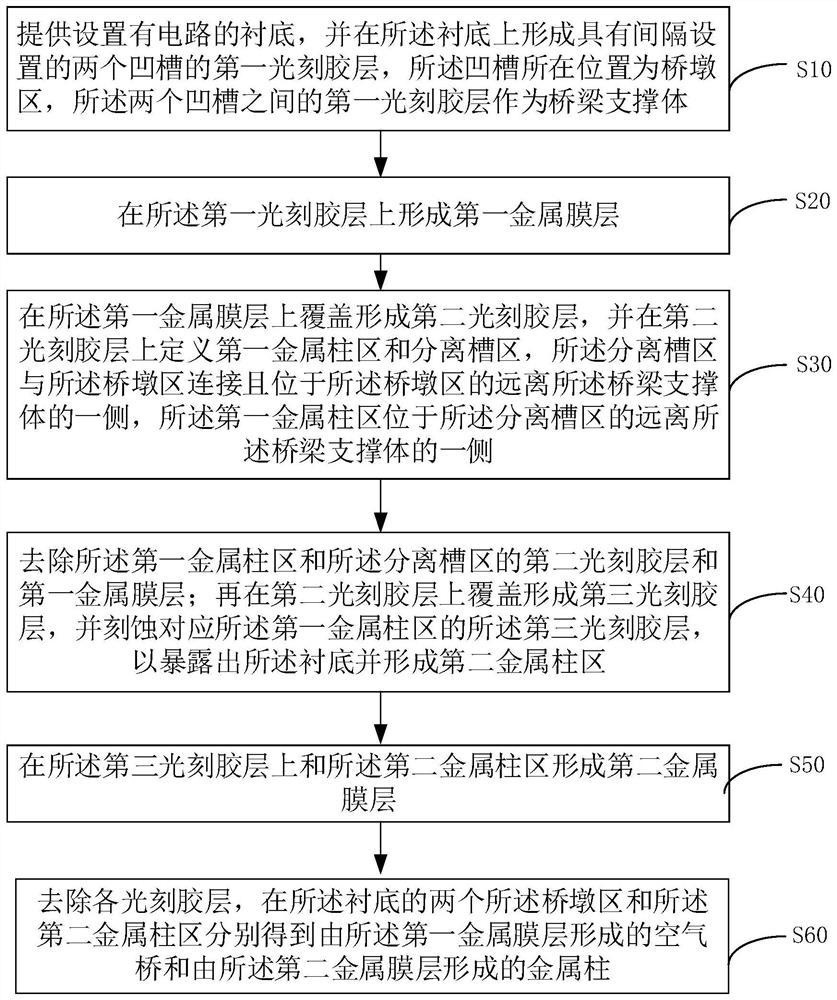

[0037] see figure 1 , the embodiment of the present invention provides a method for preparing a superconducting quantum chip, comprising the following steps:

[0038]Step S10, providing a substrate provided with a circuit, and forming a first photoresist layer having two grooves arranged at intervals on the substrate, where the grooves are located as pier regions, and the two grooves are The first photoresist layer between the grooves acts as a bridge support;

[0039] Step S20, forming a first metal film layer on the first photoresist layer;

[0040] Step S30, covering and forming a second photoresist layer on the first metal film layer, and defining a first metal column area and a separation groove area on the second photoresist layer, and the separation groove area and the bridge pier areas are connected and located on the side of the pier area away from the bridge support body, and the first metal column area is located on the side of the separation groove area away from...

Embodiment 1

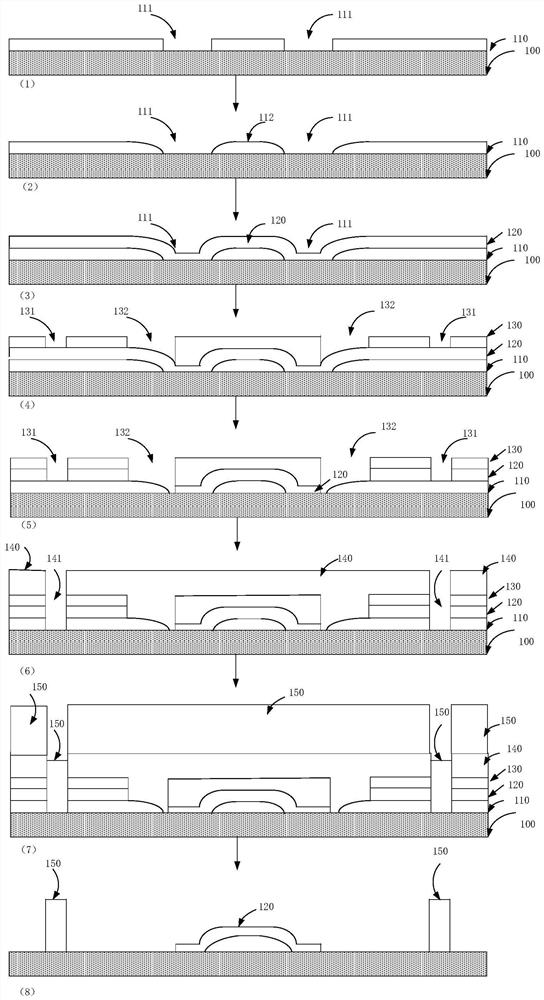

[0083] see figure 2 , the preparation method of the superconducting quantum chip is as follows:

[0084] A single crystal silicon wafer is used as a substrate, and a superconducting circuit structure is fabricated on the substrate to obtain a substrate 100 provided with circuits. The superconducting circuit structure can be provided, fabricated or formed using techniques known in the art.

[0085] (1) Form a layer of photoresist on the substrate 100 provided with the circuit, and form two grooves arranged at intervals in the photoresist to define the bridge pier region 111 to obtain the first photoresist layer 110 . The groove is the pier area 111 of the air bridge.

[0086] Specific method: use a spin coater to spin coat LOR 10B glue on the above-mentioned substrate 100 provided with a circuit, the spin coating speed is 2000 rpm, and the spin coating time is 60 sec. Use a hot plate to bake the substrate spin-coated with LOR 10B glue at 200°C for 10 minutes.

[0087] Afte...

Embodiment 2

[0106] see also figure 2 , the preparation method of the superconducting quantum chip is as follows:

[0107] A single crystal silicon wafer is used as the substrate 100, and a layer of superconducting metal film has been covered on the surface of the substrate. A superconducting circuit structure is fabricated on the substrate to obtain a substrate 100 provided with circuits. The superconducting circuit structure can be provided, fabricated or formed using techniques known in the art.

[0108] (1) Form a layer of photoresist on the substrate 100 provided with the circuit, and form two grooves arranged at intervals in the photoresist to define the bridge pier region 111 to obtain the first photoresist layer 110 . The groove is the pier area 111 of the air bridge.

[0109] Specific method: Spin-coat S1813 photoresist on the substrate in step 1 at a rotation speed of 800 rpm, and bake on a hot plate at 115° C. for 2 minutes after the coating is completed.

[0110] The pier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com