A composite busbar for charger integrated capacitor

A technology of integrating capacitors and composite busbars, which is applied in electrical components, output power conversion devices, and structural components of conversion equipment, etc. DC filtering, improving space utilization, and reliable electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

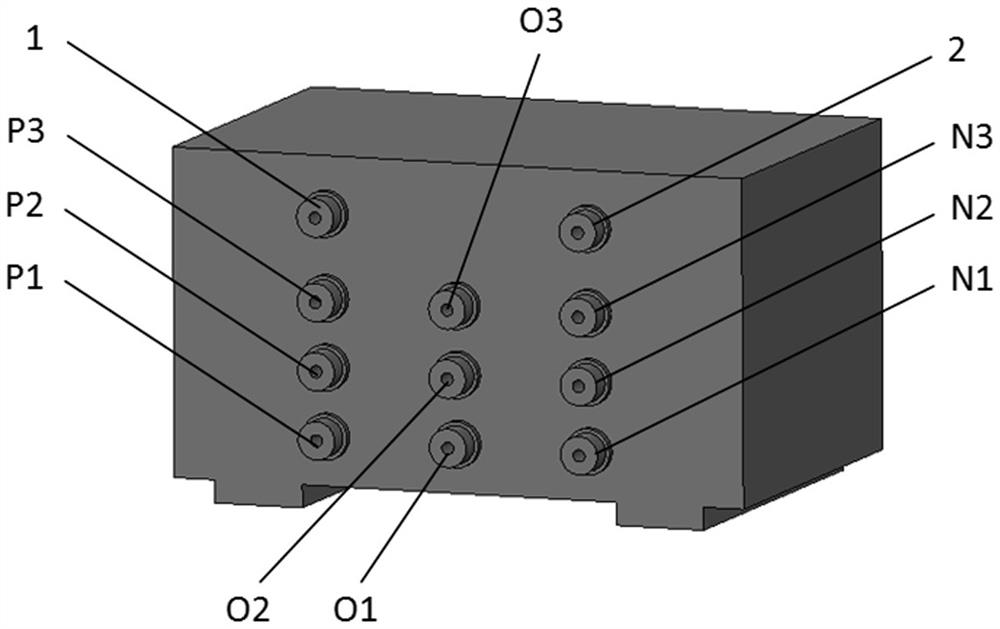

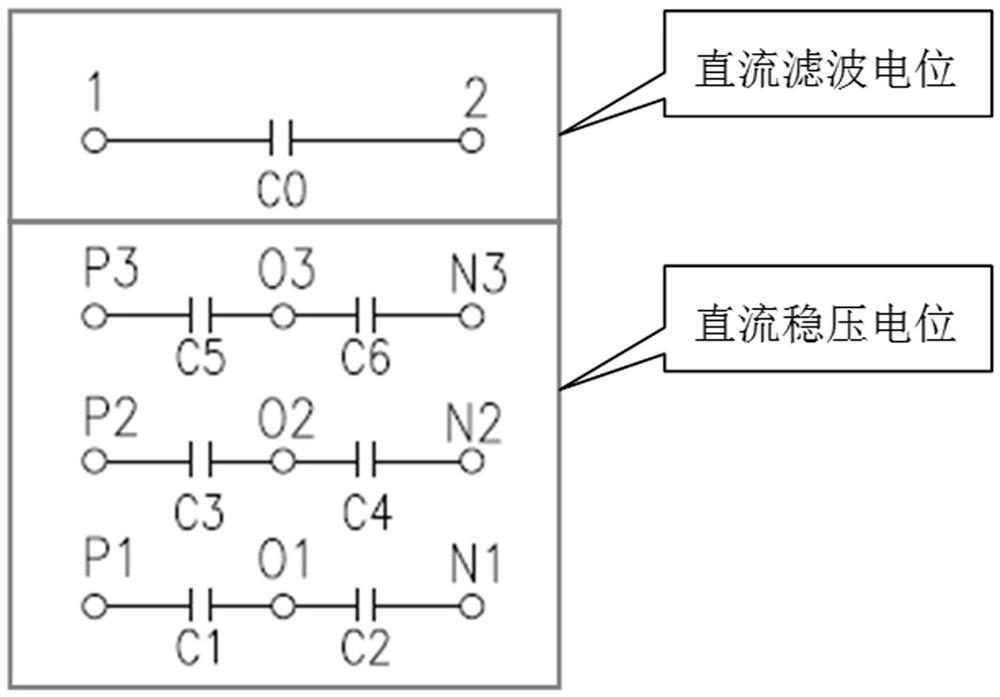

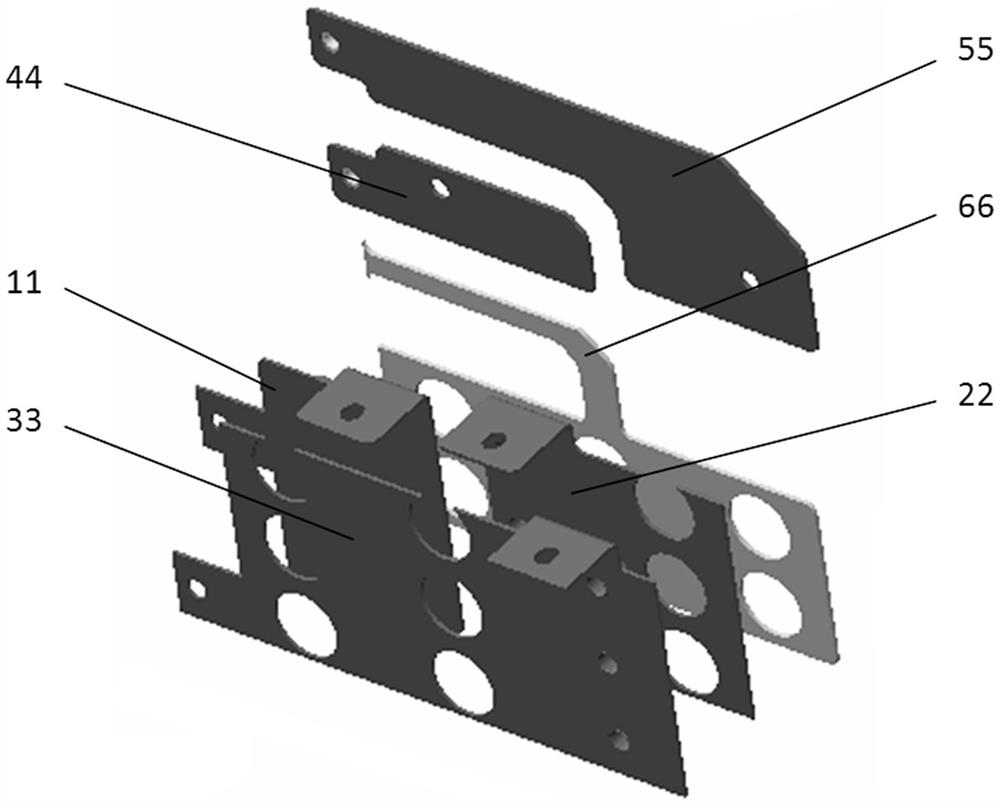

[0032] As shown in the figure, a composite busbar for the integrated capacitor of the charger is designed with 5 layers of busbars stacked from top to bottom, consisting of U busbar 11, V busbar 22, W busbar 33, positive busbar 44. The negative busbar is composed of 55. It is electrically connected to the P-phase, O-phase, N-phase, 1-phase and 2-phase of the integrated capacitor respectively through self-locking nuts. Insulation layers are used to isolate the busbars of each layer. The physical layer structure of the composite busbar is 3 layers.

[0033] The P1, P2 and P3 phases of the capacitor are short-circuited through the U busbar 11, and two P-phase connection points 111 and 112 are drawn out, which are respectively connected to the power module and the integrated reactor;

[0034] The O1, O2, O3 phases of the capacitor are short-circuited through the V busbar 22, and an O-phase connection point 221 is drawn out to connect with the power module;

[0035] The V busbar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com