Arranging construction method for six types of wires of IDC machine room

A construction method and technology of six types of cables, applied in the field of communication, can solve the problems of inability to find faulty lines in time, poor cable properties, difficult disassembly, etc., to facilitate expansion and maintenance, solve the problem of cable heat dissipation, and simplify construction. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

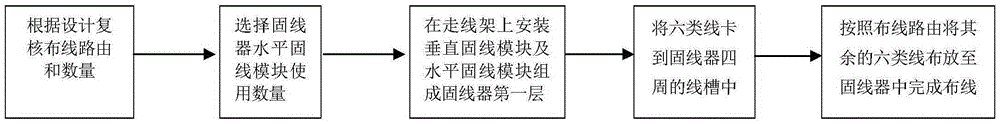

[0031] The specific steps of the laying construction method of six types of lines in an IDC machine room of the present invention are as follows: figure 1 As shown, its specific implementation steps are:

[0032] Step 1: Review the wiring routing and quantity according to the design;

[0033] Step 2: Select the number of horizontal wire fixing modules used by the wire fixing device;

[0034] Since the right-angle wire fixing module of the wire fixing device plays the role of fixing the wire fixing device on the cable rack and binding the six types of wires, the horizontal wire fixing module mainly plays the role of adding wire slots according to the wiring quantity requirements and flexibly adjusting the specifications of the wire fixing device effect;

[0035] Step 3: Install the vertical wire fixing module and the horizontal wire fixing module on the cable tray to form the first layer of the wire fixing device;

[0036] According to the amount of wiring, it is necessary t...

Embodiment 2

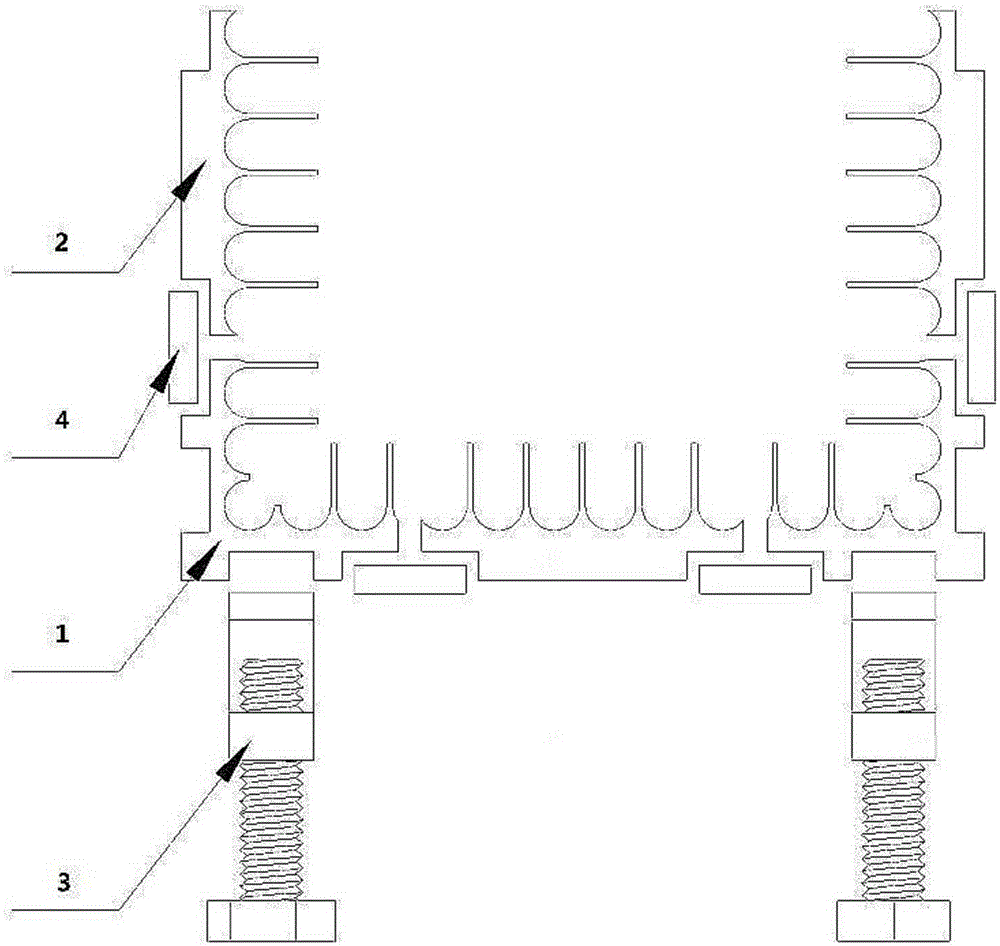

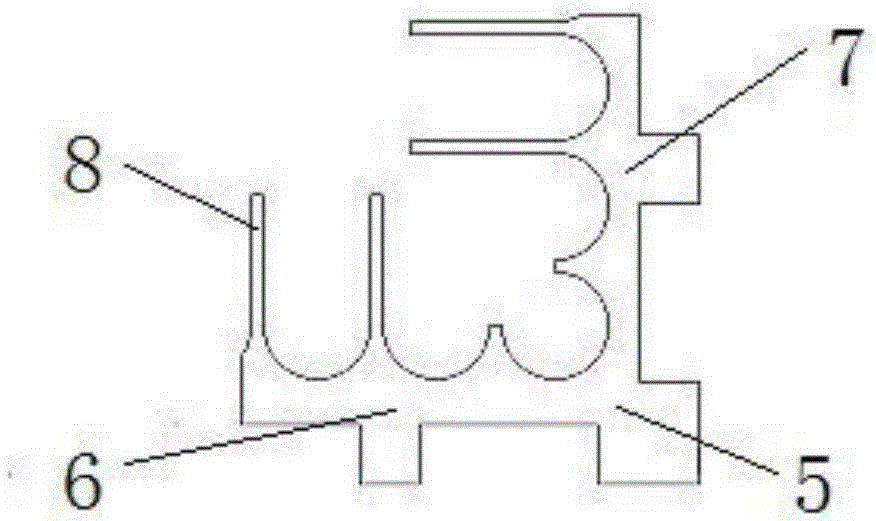

[0043] Figure 2 to Figure 7 In the embodiment, a six-category line fixing device in an IDC computer room is composed of two right-angle fixing modules 1, multiple horizontal fixing modules 2, cable rack reinforcements and 3 module connecting pieces 4, which can be arranged as required Any combination of the number of cables placed. The horizontal wire fixing module 2 is arranged along the horizontal direction and the vertical direction, wherein the horizontal wire fixing module 2 is detachably arranged between the two right angle wire fixing modules 1, and the horizontal wire fixing module 2 is arranged according to the needs Set several, the horizontal wire fixing module 2 in the vertical direction is set on the right angle wire fixing module 1 in a detachable manner perpendicular to the horizontal wire fixing module 2, and several horizontal wire fixing modules 2 in the vertical direction are set as needed, The right-angle wire fixing module 1 and the horizontal wire fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com