Auxiliary heating junction box of YBX4 high-efficiency explosion-proof three-phase asynchronous motor

A three-phase asynchronous, auxiliary heating technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large size of the junction box and inconvenient wiring, and achieve the effect of reducing the size, convenient wiring and good electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

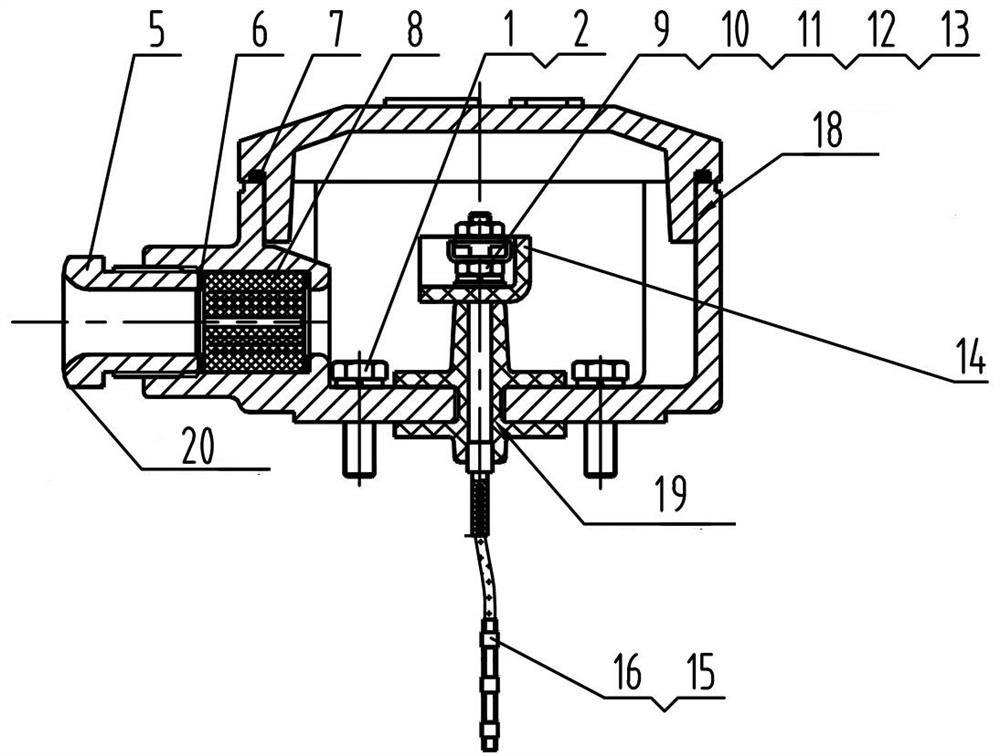

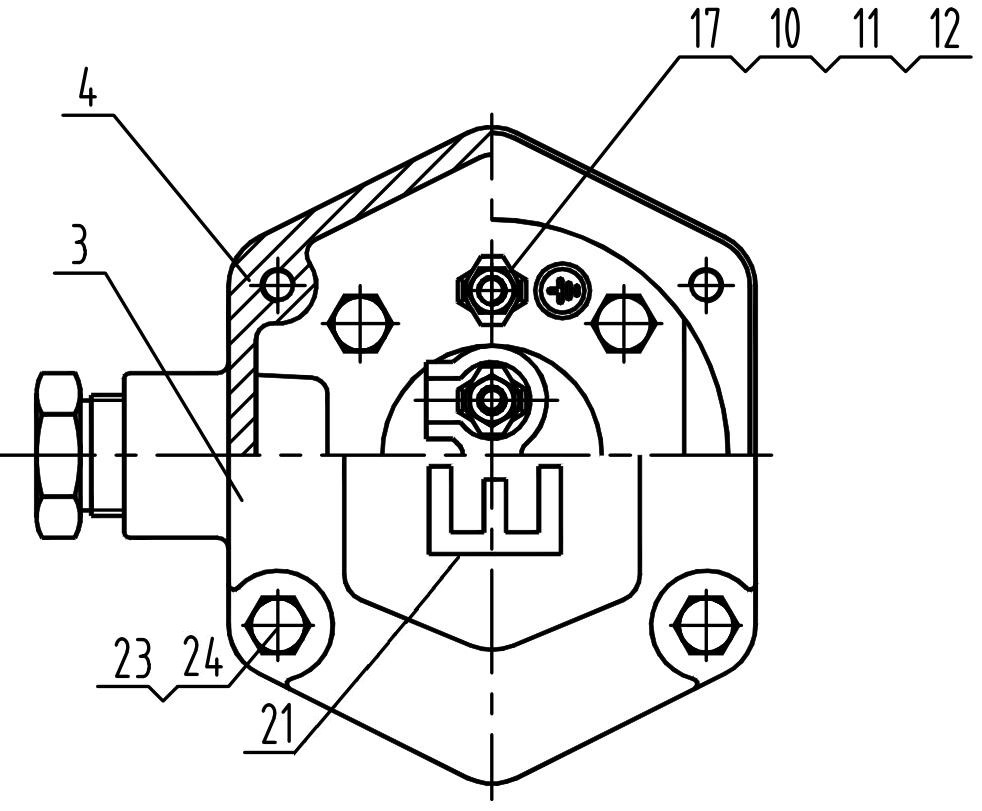

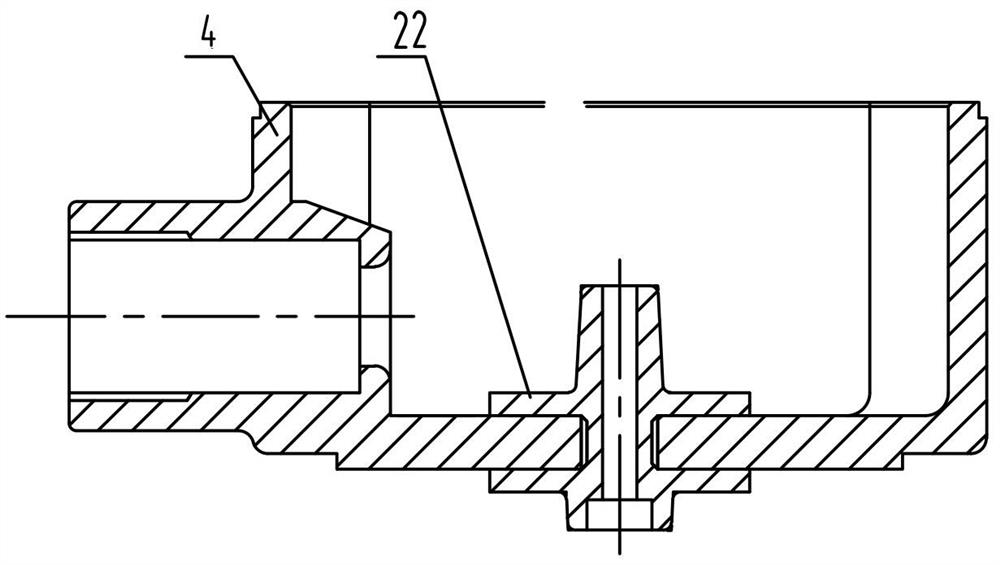

[0034] refer to Figure 1-6 , this embodiment provides a YBX4 high-efficiency flameproof three-phase asynchronous motor auxiliary heating junction box, including a junction box seat 4, a junction box bucket 20 connected to one side of the junction box seat 4, and a junction box with the junction box seat 4. The junction box cover 3 connected to the top of the box seat 4; the interior of the junction box seat 4 is provided with wiring components, and the wiring components include a terminal cover 22 integrally die-cast with the terminal box seat 4, and are arranged on the terminal cover 22 The upper wiring mounting plate 14 and the wiring bolts 9 passing through the terminal sleeve 22 and the wiring mounting plate 14 .

[0035] The junction box base 4 is fixedly installed on the motor base through the first bolt 1 , and the first washer 2 is arranged on the first bolt 1 .

[0036] The junction box base 4 is provided with a grounding bolt 17 , and the grounding bolt 17 is provi...

Embodiment 2

[0046] refer to Figure 1-6 , this embodiment provides a YBX4 high-efficiency flameproof three-phase asynchronous motor auxiliary heating junction box, which is an improvement on the basis of Embodiment 1:

[0047] A first explosion-proof surface 18 is set between the junction box cover 3 and the junction box seat 4: L≥11, ic≤0.15; the upper and lower ends of the terminal cover 22 protrude from the junction box seat 4, and the junction box The lower part of the seat 4 is wrapped, and a second flameproof surface 19 is set between the junction box seat 4 and the terminal cover 22: L≥28, ic≤0.2. The net volume of the junction box is ≤500cm 3 .

Embodiment 3

[0049] refer to Figure 1-6 , this embodiment provides a YBX4 high-efficiency flameproof three-phase asynchronous motor auxiliary heating junction box, which is an improvement on the basis of Embodiment 2: the junction box bucket 20 includes a connection with the junction box seat 4 The sealing ring 8 and the metal washer 6 provided at the place, and the compression nut 5 at the end. Lead enters from terminal box bucket 20, and after being connected on the terminal bolt 9, tighten with hold-down nut 5, easy and simple to operate. The sealing ring 8 is made of nitrile rubber, and the compression nut 5 and the metal washer 6 are both made of Q235A. The junction box cover 3 is provided with an explosion-proof mark 21 . The invention can meet the requirements of ExdIMb and ExdIIB T4 Gb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com