Metal sheet heel and manufacturing method thereof

A manufacturing method and metal sheet technology, applied in the direction of heels, heel pads, footwear, etc., can solve the problems of increased manufacturing costs, environmental pollution, large usage of shoe molds, etc., to achieve enhanced wear resistance, anti-corrosion Good shedding, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The manufacturing method of the heel with metal sheet provided by the present invention comprises the following steps:

[0094] S1, prepare the base material;

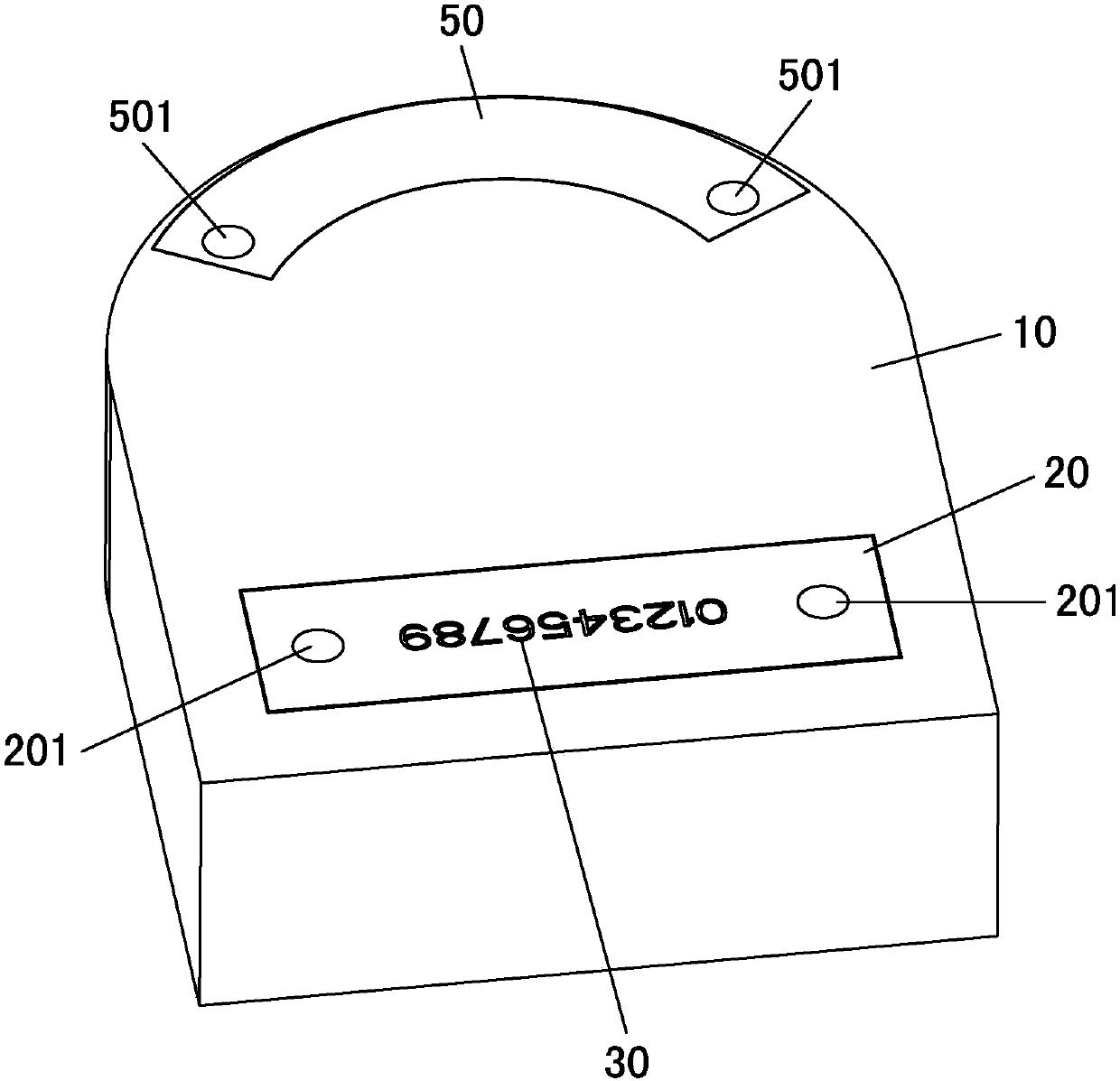

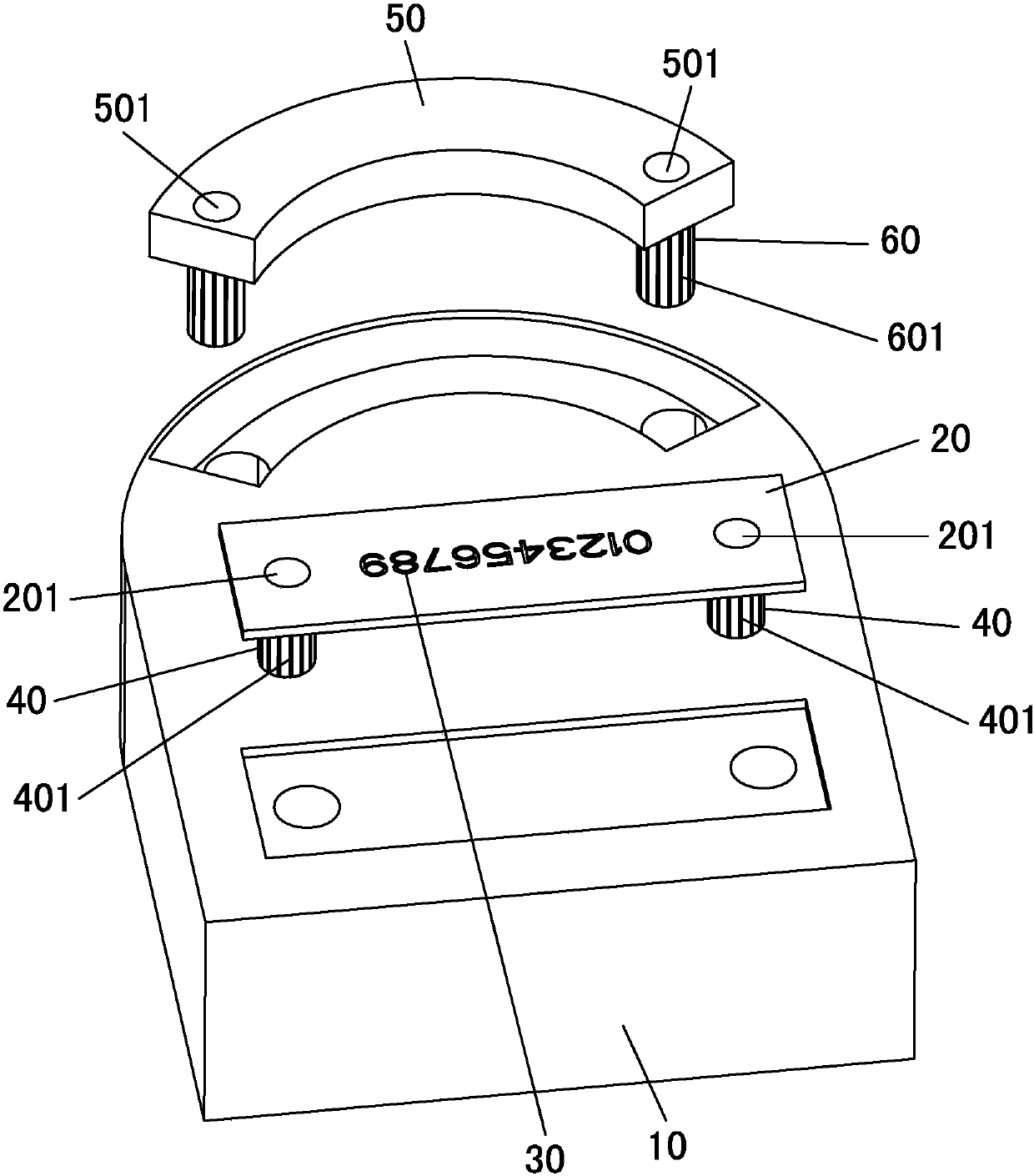

[0095] S11, preparatory shoe mold 70, series code metal sheet 20, two metal hollow tubes A40 and filling material for making heel; wherein,

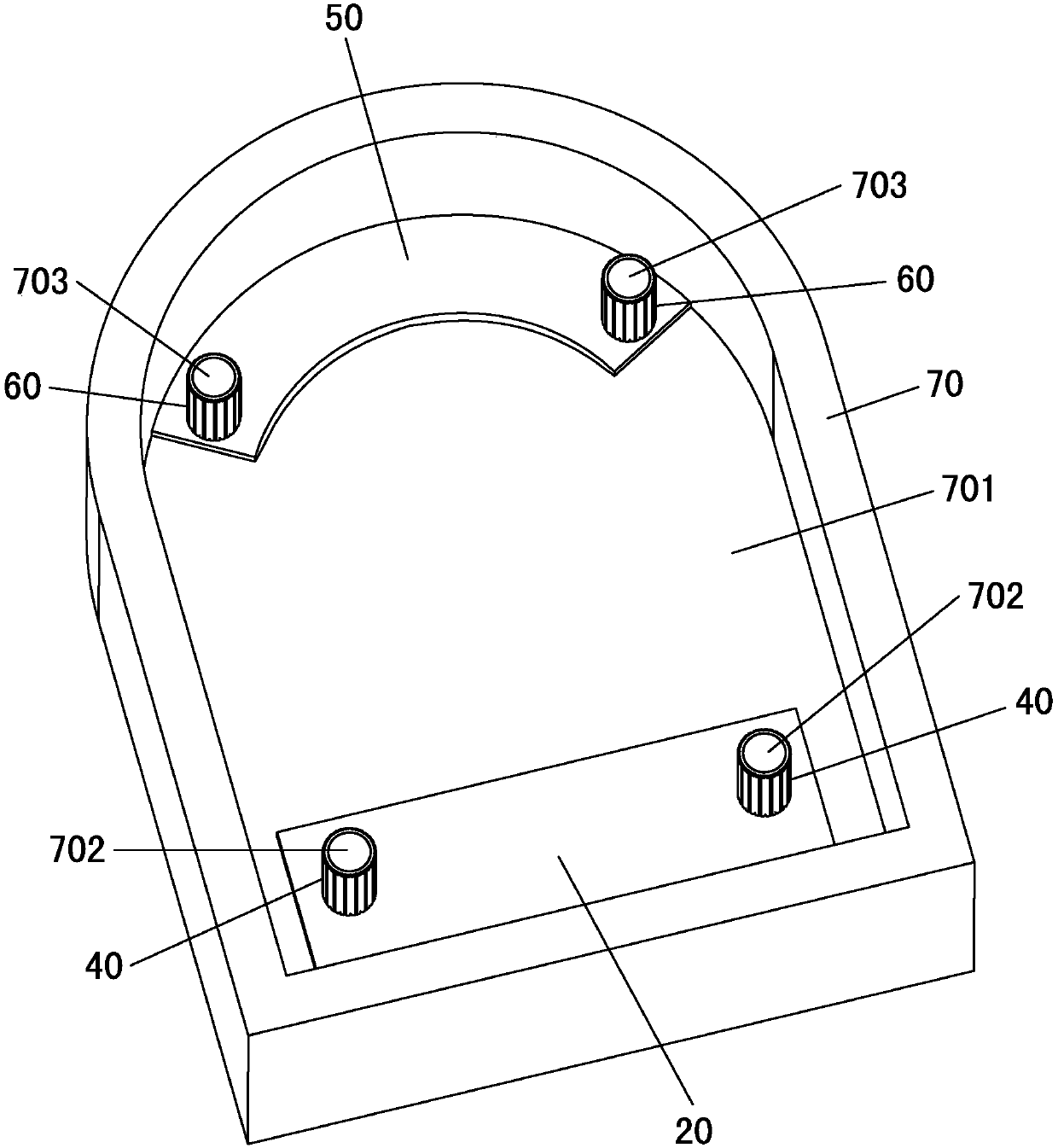

[0096] The upper end surface of the shoe mold 70 is provided with a cavity 701 for forming a heel, and the front end of the inner bottom surface of the cavity 701 is fixed with two metal columns A702 side by side;

[0097] The lower bottom surface of the series code metal sheet 20 is preset with a series code 30, and the two ends of the lower bottom surface of the series code metal sheet 20 are respectively opened in a through hole A201 that passes through to its upper end surface, and between the two through holes A201 The distance between them is equal to the distance between the two metal pillars A702, and the size of the two through holes A201 matches the size of the ...

Embodiment 2

[0118] On the basis of Embodiment 1, step S1 of the present invention also includes step S12; step S2 also includes step S23 and step S24; wherein,

[0119] Step S12, preparing wear-resistant metal sheet 50 and two metal hollow tubes B60;

[0120] The rear end of the inner bottom surface of the cavity 701 is fixed with two metal pillars B703 side by side;

[0121] The two ends of the lower bottom surface of the wear-resistant metal sheet 50 are respectively opened in through holes B501 passing through to the upper end surface thereof, the distance between the two through holes B501 is equal to the distance between the two metal pillars B703, and The size of the two through holes B501 matches the size of the two metal pillars B703;

[0122] The outer walls of the two metal hollow tubes B60 are uniformly provided with a plurality of filling grooves B601 along their length directions, and the inner diameters of the two metal hollow tubes B60 are equal to the diameters of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com