Liquid suction device

A suction device and liquid technology, applied in vacuum cleaners, cleaning carpets, cleaning floors, etc., can solve problems such as low-intensity negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

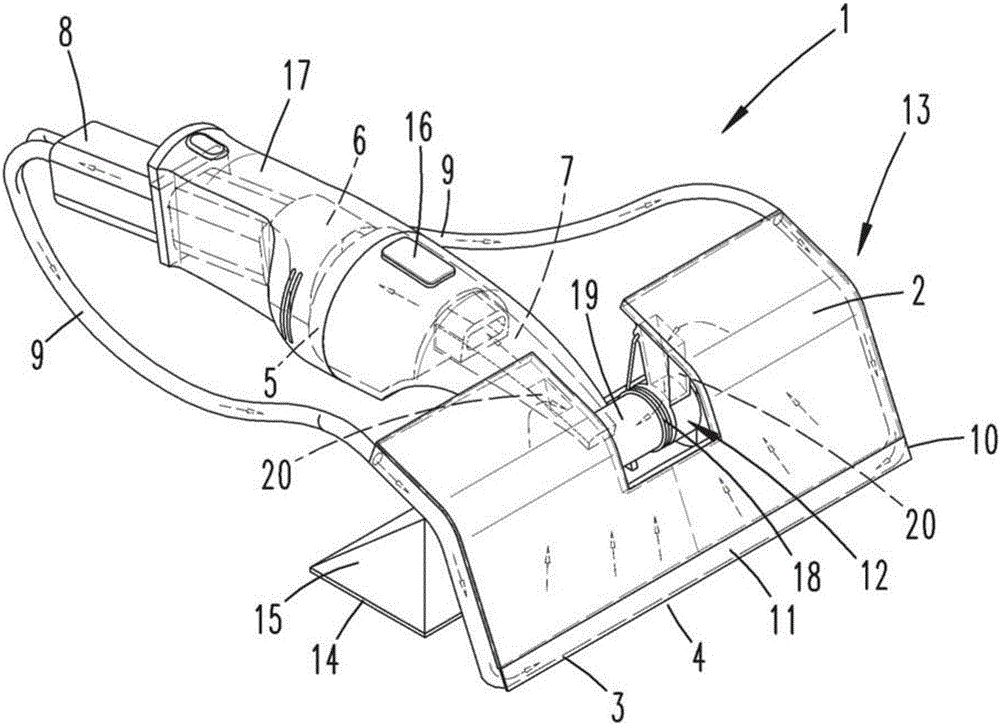

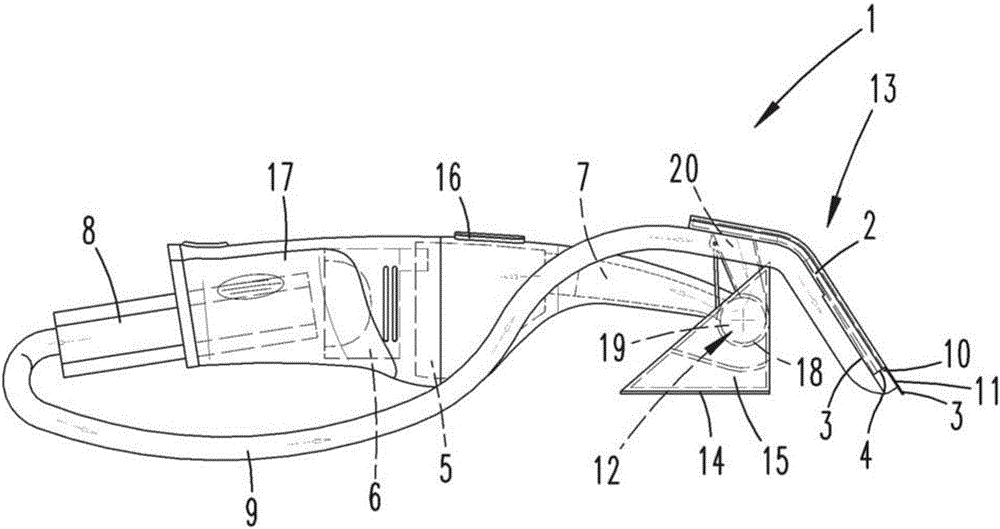

[0022] A wet cleaning device 13 is shown, designed here as a hand-held guided wet cleaning device, which has a liquid suction device 1 as well as a cleaning element 14 and a liquid application device 15 . The cleaning element 14 and the liquid application device 15 are designed as a common surface installation with a liquid reservoir. On the side facing the surface to be cleaned, the liquid tank has a cleaning element 14 , designed here as a cleaning cloth. The liquid application device 15 and the cleaning element 14 are connected to each other through the perforations of the wall of the liquid application device 15 in such a way that the liquid is continuously supplied from the storage tank of the liquid application device 15 to the cleaning element 14 and is thus applied to the surface to be cleaned. in the cleaning process.

[0023] The liquid suction device 1 of the wet cleaning device 13 has a suction head 2 which is designed here as a flat, double-walled part between wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com