Needle head cleaning mechanism

A technology for cleaning mechanisms and needles, which is applied in the direction of spraying devices, coatings, and devices for coating liquid on the surface, etc. It can solve the problems of needle deformation, inability to accurately ensure the position and height of dispensing, product damage, etc., and prevent needle deformation , saving materials and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

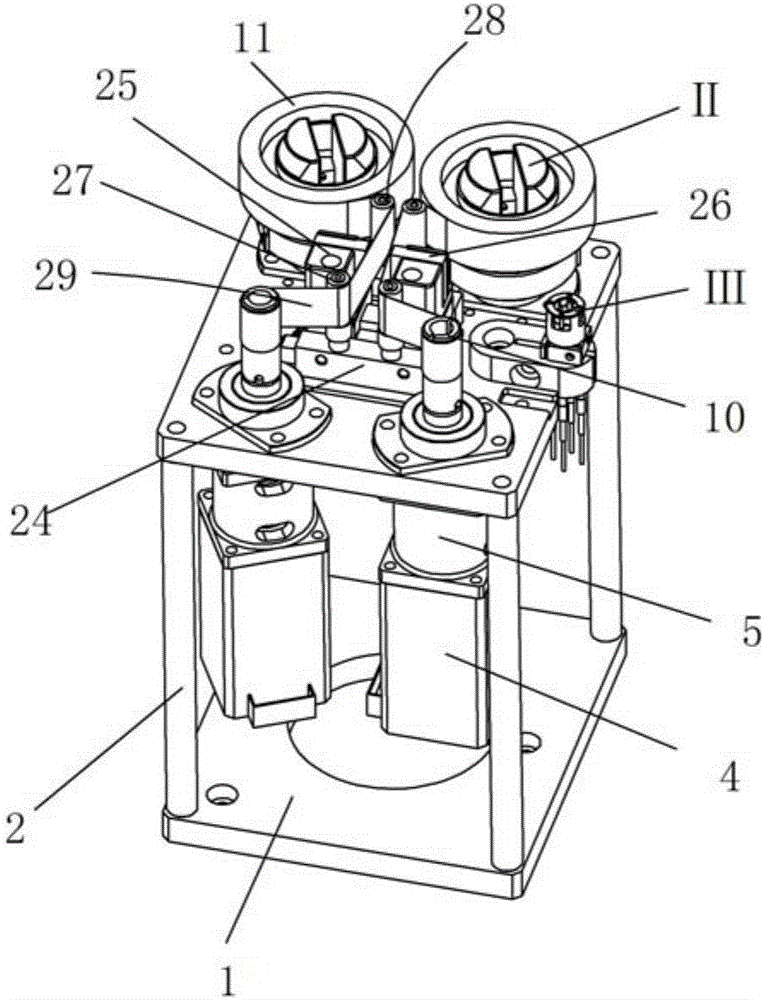

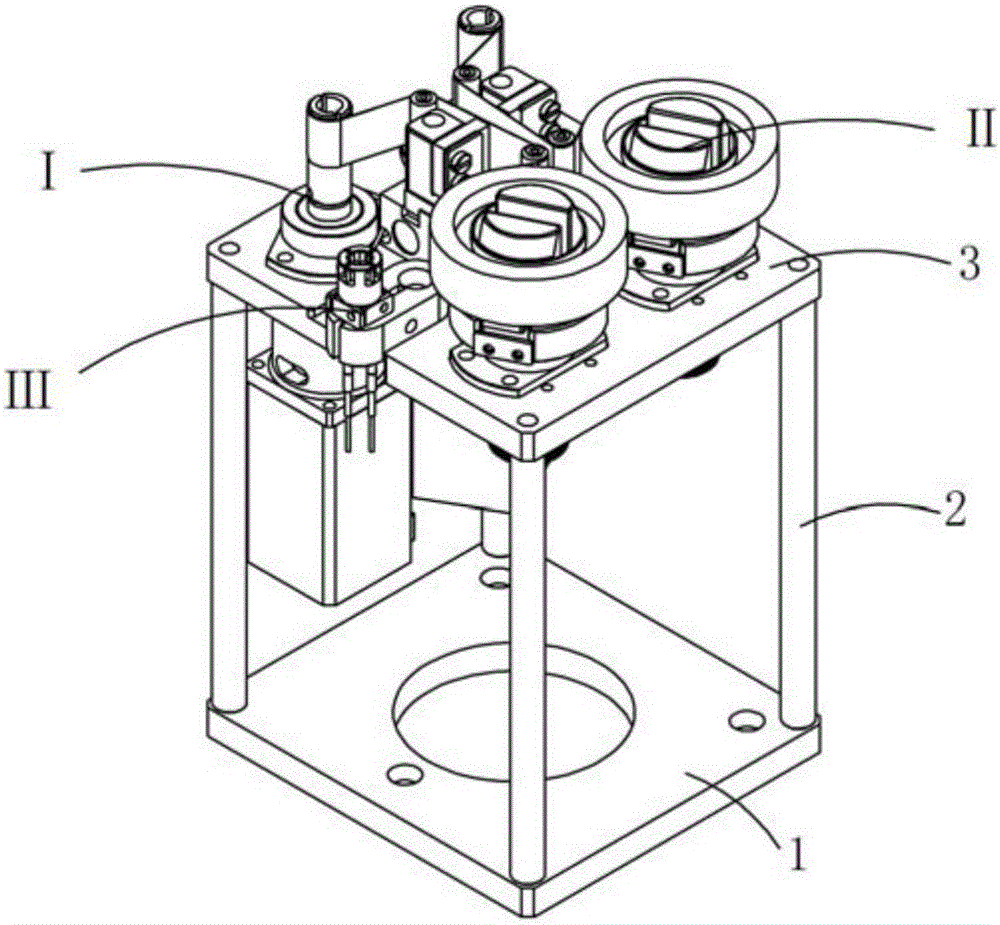

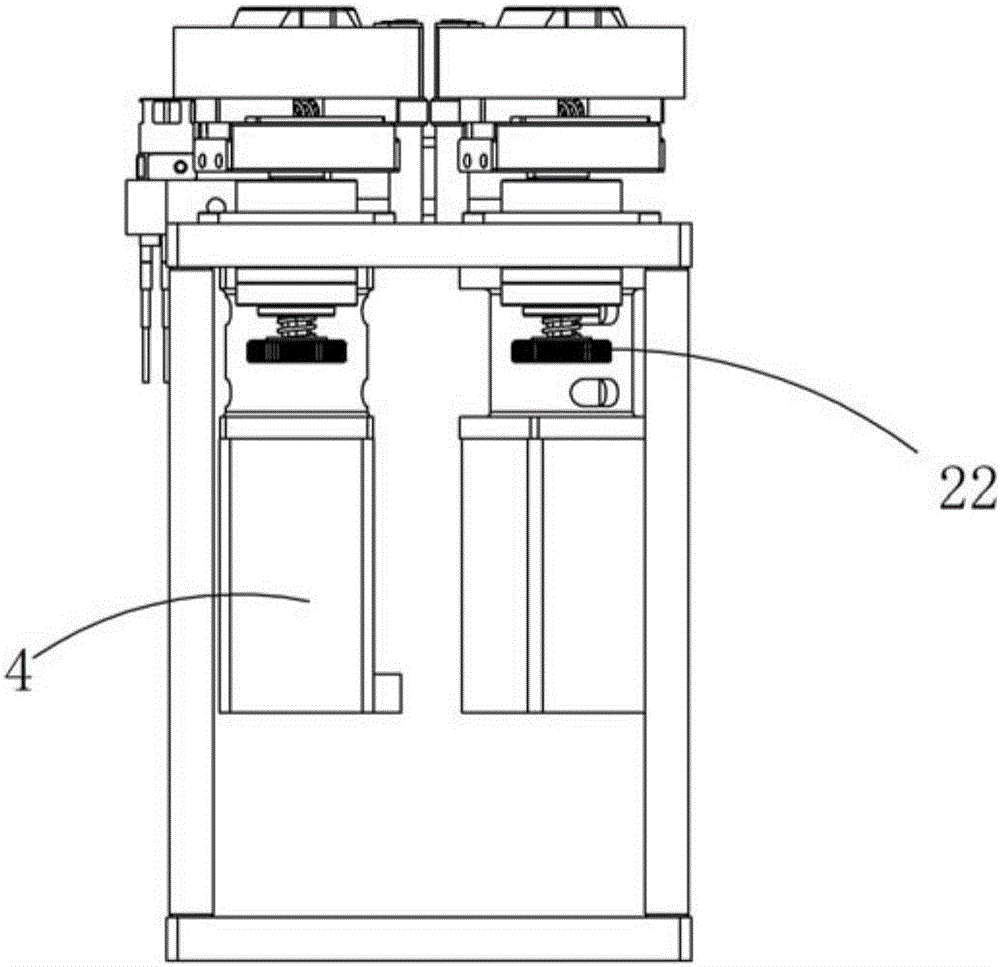

[0030] See attached Figure 1-10 , a needle cleaning mechanism, comprising a base plate 1, on which a mounting plate 3 is installed through support columns 2, there are four sets of support columns, and the four sets of support columns are symmetrically installed at the four corners of the base plate. Both the base plate and the installation plate are of flat plate structure, and the base plate and the installation plate are parallel to each other, and the cross-sectional dimensions of the base plate and the installation plate are the same.

[0031] The left and right sides of the lower part of the mounting plate are respectively equipped with a group of stepping motors 4, two groups of stepping motor mounting plates 5 are installed on the bottom of the mounting plate, and a group of stepping motors are installed on each group of stepping motor mounting plates. , and each set of stepping motors is located between the bottom plate and the mounting plate.

[0032] The main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com