Mode for installing car door waterproof membrane

An installation method and technology of waterproof membrane, applied in the direction of doors, vehicle parts, transportation and packaging, etc., can solve the problems of long working hours, the accuracy of pasting is greatly affected by personnel factors, and the manufacturing cost of waterproof membrane is high, achieving low cost, convenient installation, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

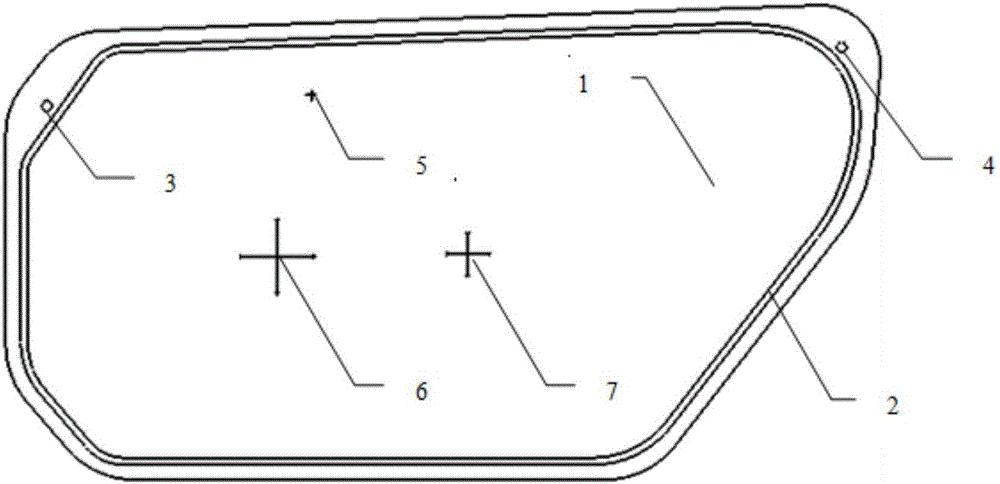

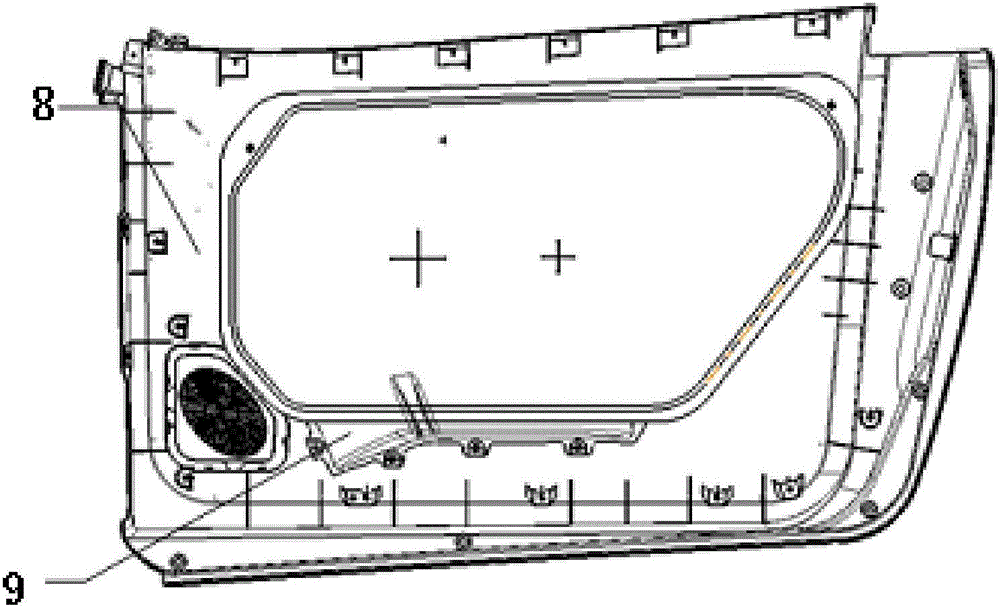

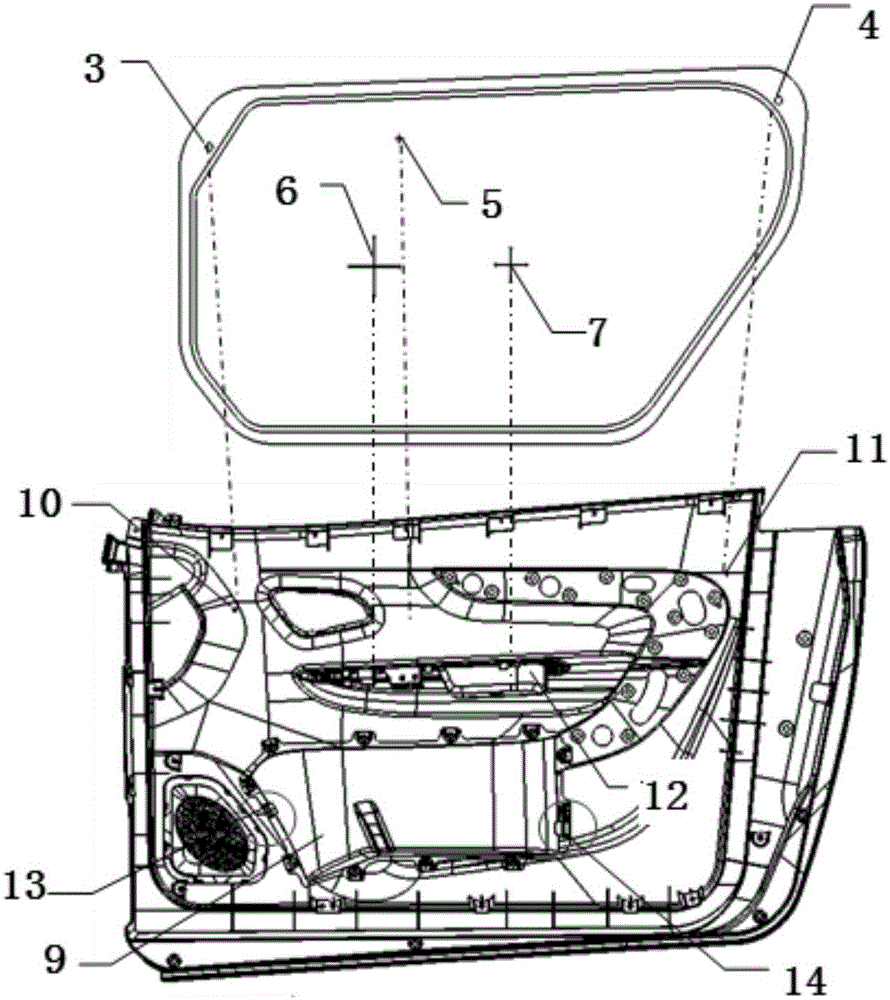

[0025] The installation method of the car door waterproof membrane of the present invention, such as figure 1 As shown, the door waterproof membrane 1 is a PE film with a thickness of 0.14mm-0.2mm formed by punching, and is bonded to the door inner guard body 8 by butyl glue 2. The door waterproof membrane 1 is provided with Positioning hole 3 on the left side of the waterproof membrane, positioning hole 4 on the right side of the waterproof membrane, installation via hole 5 of the inner opening wire drawing, via hole 6 of the switch panel plug-in, and via hole 7 of the sheet metal bracket.

[0026] The installation method of the body waterproof membrane includes the following steps:

[0027] 1) Hold the waterproof membrane 1 and tear off the release paper;

[0028] 2) Align the left position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com