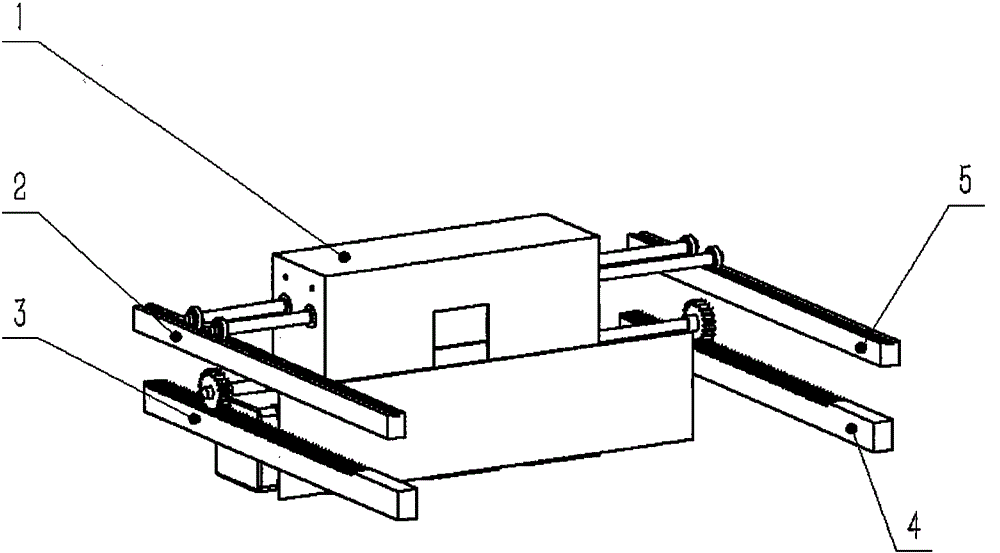

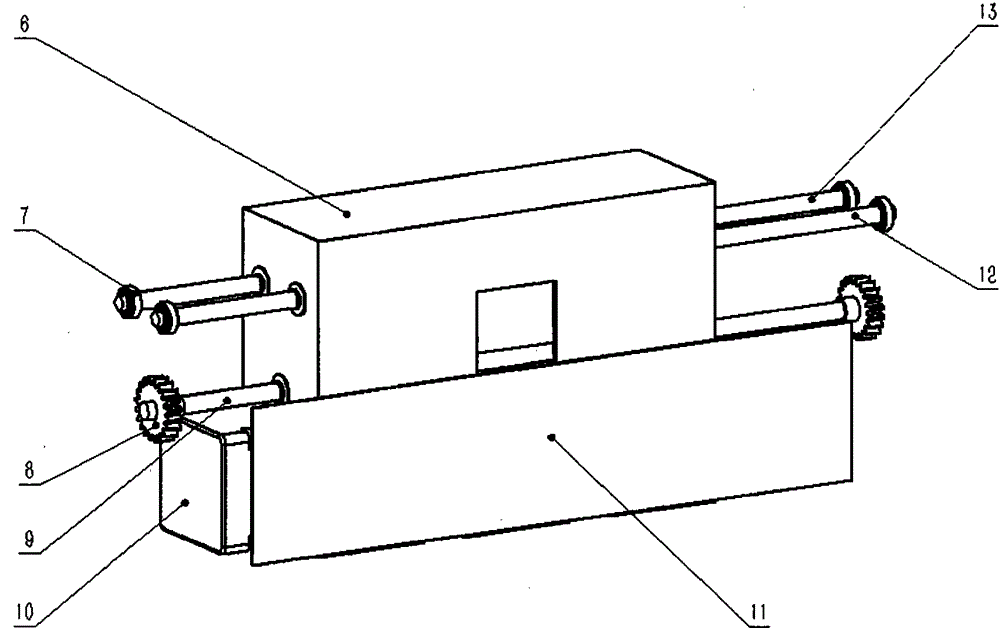

Automatic bill/paper inlet pressure regulating device

An automatic adjustment and pressure technology, applied in the directions of transportation and packaging, object separation, pile separation, etc., can solve the problems of large friction, affecting the transfer effect of bills or paper, unstable tension, etc., to achieve stable performance and avoid bills or paper. Superposition phenomenon, the effect of high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

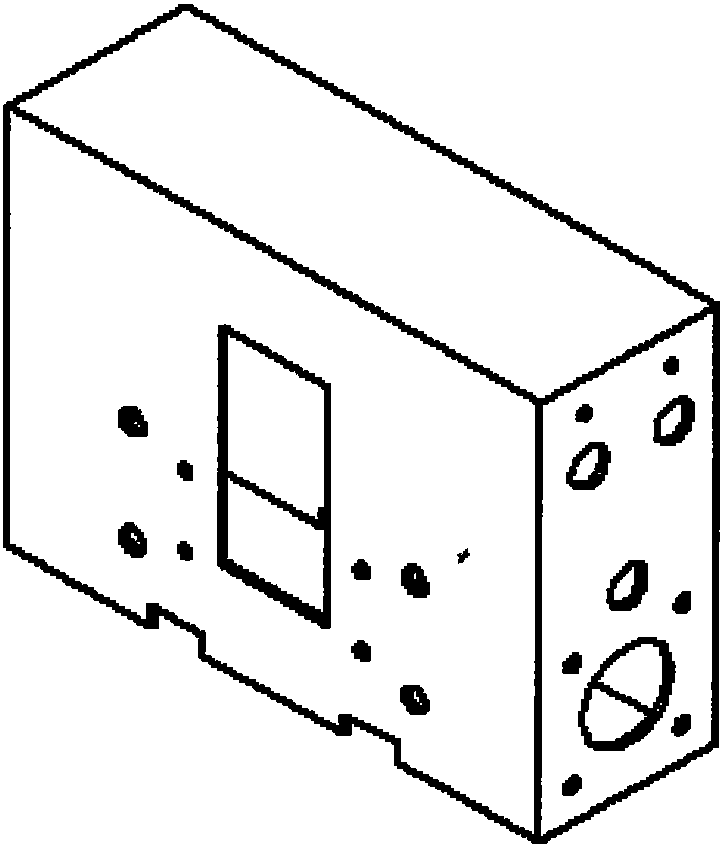

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] The structure of the pressure control device is as Figure 4 As shown, four compression springs (14) with the same length and symmetrical distribution are sleeved in the four studs of the press (paper) plate (19), and the studs can be mounted on the flange embedded in the transmission case (6). The shaft sleeve (15) moves forward and backward, and the rear end of each flange shaft sleeve (15) is connected with the adjustment nut (16) to press the ticket (paper) plate (19) and the compression spring (14) to the transmission box (6) superior. By adjusting the adjusting nut (16), the range of pressure produced by the pressing ticket (paper) board can be set according to bills of different materials and thicknesses. The adjustment bolt (17) that is connected on the pressing ticket (paper) plate (19) contacts with the contact swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com