Lifting mechanism for automatic liquid-based thin-layer cell preparation machine

A thin-layer cell and lifting mechanism technology, which is used in lifting devices, preparation of test samples, sampling, etc., can solve the problems of easy rotation of circular racks, unsmooth lifting and sliding, and difficulty in ensuring straight up or down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

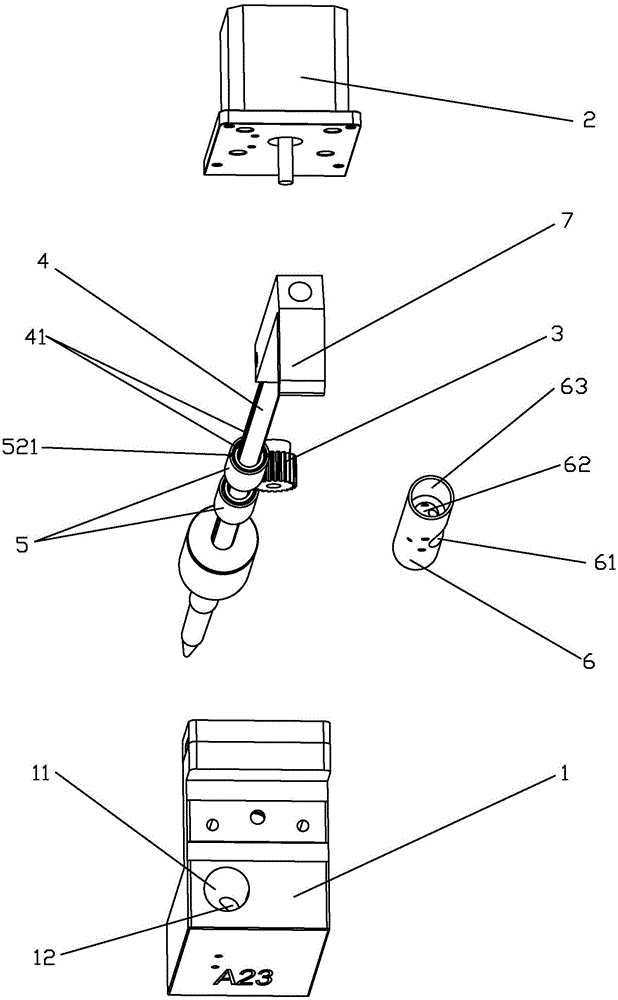

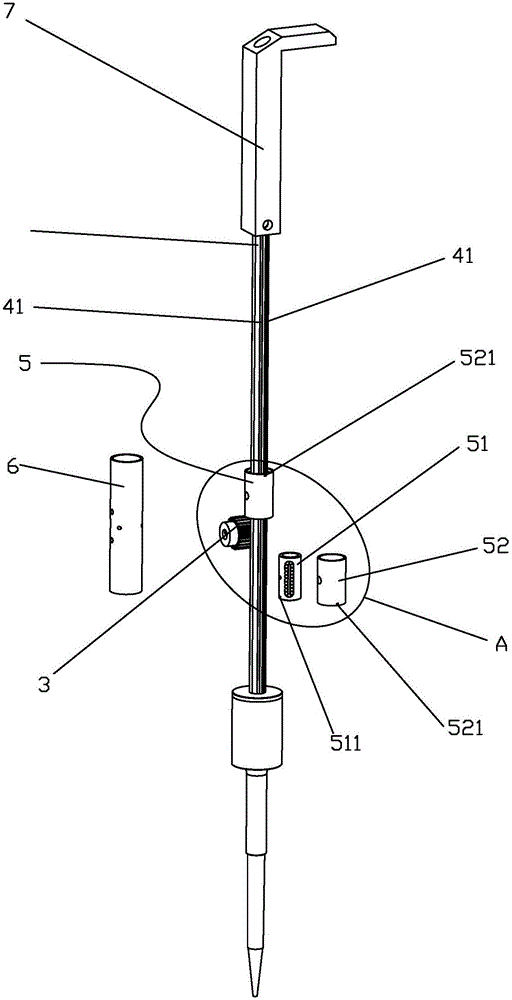

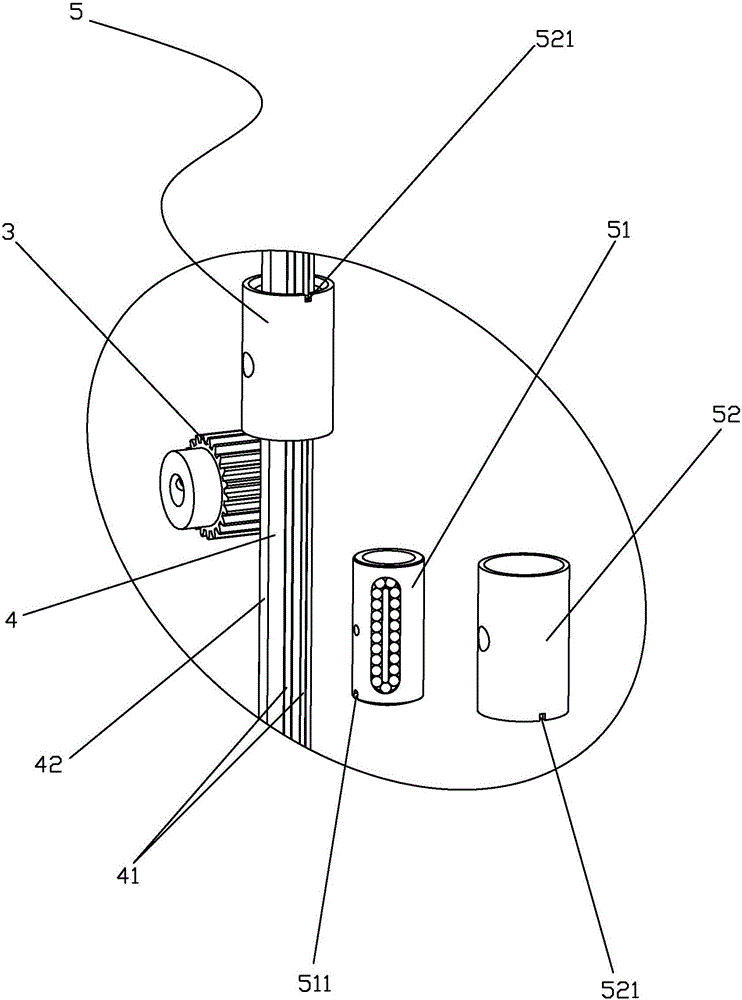

[0027] Such as Figure 1-8 As shown, a lifting mechanism for an automatic liquid-based thin-layer cell film maker includes a motor 2 arranged on the installation module 1, a gear 3 connected to the output end of the motor 2, and a lifting rack 4 meshing with the gear 3. The lifting The teeth on the rack 4 are arc-shaped teeth, and the arc length of the arc-shaped teeth is at least one-third of the circumferential length of the elevating rack 4 , and the elevating rack 4 is provided with a linear bearing 5 . Correspondingly, there are three groups of balls in the linear bearing 5 , preferably each group of balls is a double row of balls, and more preferably, each group of balls is arranged in a waist shape. The tooth width of lift rack 4 is maximized like this, can maximize the depth of tooth, prevents gear and lift rack from rotating and slipping. Because the conventiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com