Misplug-proof terminal set used for sewing equipment

A technology of anti-mis-insertion and terminal group, applied in the direction of sewing machine control devices, sewing equipment, sewing machine components, etc., can solve the problems of sewing machine damage, personal injury, mistakes, etc., prevent mis-insertion and mis-insertion, and facilitate popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

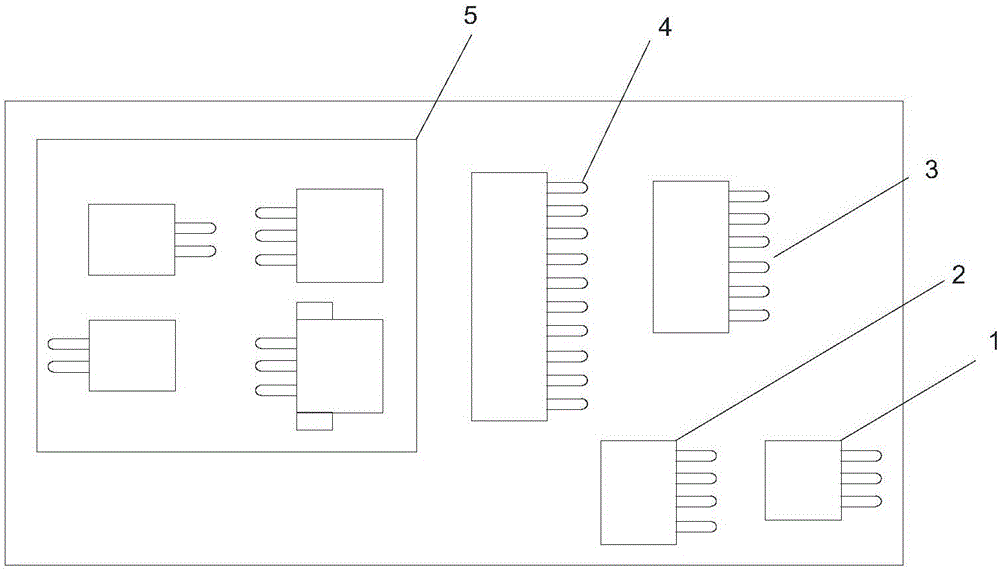

[0014] like figure 1 As shown, in this embodiment, the terminals connected with various functions adopt measures such as different number of digits and different pin spacings, so as to prevent mis-insertion and mis-insertion.

[0015] Specifically, the white terminals used for the power supply interface of the control board are 6 bits, and the pin spacing is 2.5mm; the white terminals used for digital detection input are 4 bits, and the pin spacing is 2.5mm, and the white terminals are used for the pedal signal detection input. 3 bits, pin spacing 2.5mm, white terminals for motor control 10 bits, pin spacing 2.5mm, white terminals for solenoid valve control output 4*2 bits, pin spacing 4.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com