Railway ballastless track supporting layer and lower structure detaching and replacing method

A technology of ballastless track and support layer, which is applied in the direction of track, track laying, track maintenance, etc., to achieve the effect of convenient and flexible construction, low construction difficulty and small structural disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

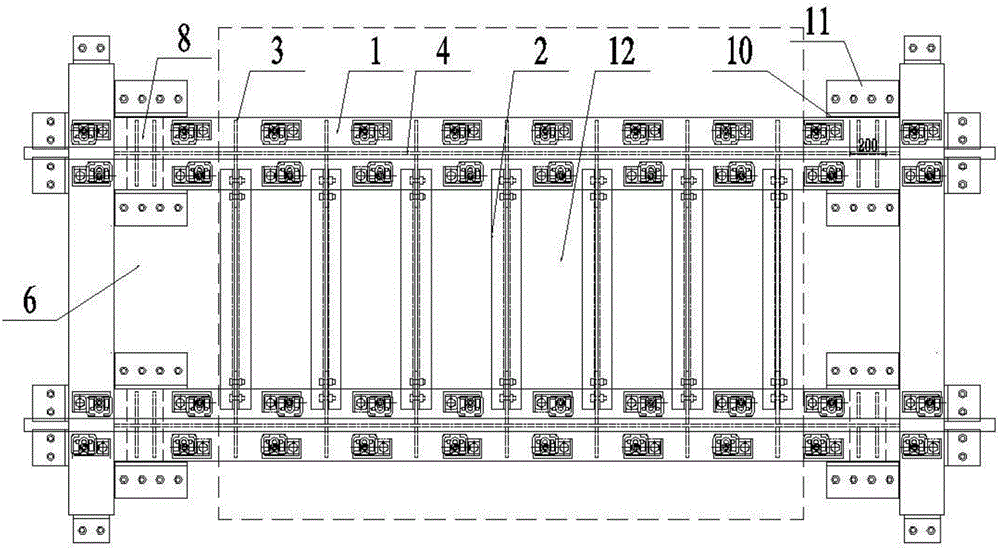

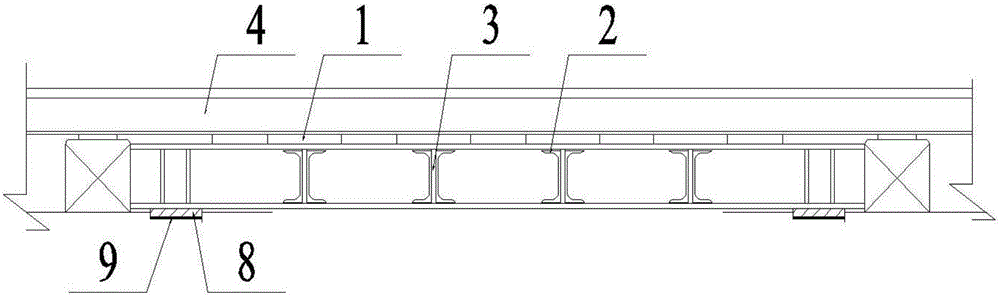

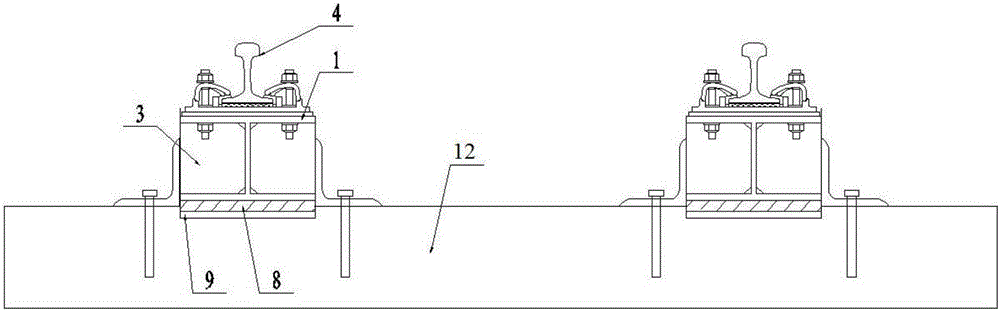

[0031] Such as Figure 1~5 , the method for removing and replacing the support layer and the substructure in this embodiment is to use steel pad beams to be erected on the second support layer 12 that needs to be removed for construction (such as figure 1 Shown in the dotted line box in ) as the supporting structure of the passage rail 4, to ensure the normal operation of the track line. The structure of the steel pad beam is as figure 1 As shown, it includes two longitudinal beams 1 arranged longitudinally along the track, the longitudinal beams 1 are I-shaped steel structures, and the webs of the longitudinal beams 1 are arranged vertically. The two longitudinal beams 1 are connected by the beam 2 arranged horizontally along the track to form an overall structure. The beam 2 is usually assembled by two pieces of channel steel. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com