Synchronous lifting gate

A synchronous lifting and gate technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as insufficient gate slot accuracy, troublesome synchronous debugging of lifting wire ropes, and hoist drum climbing rope climbing phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

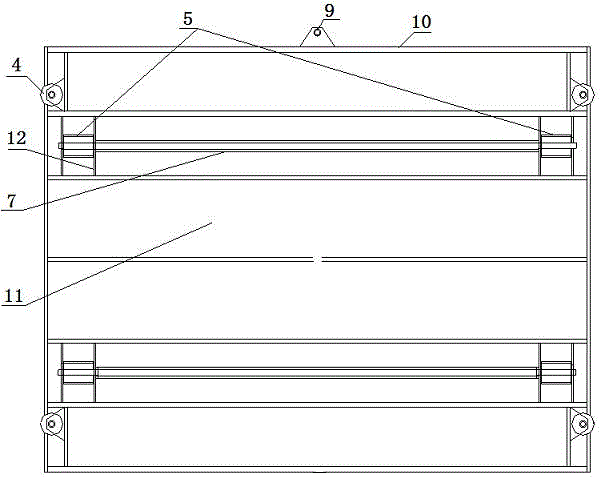

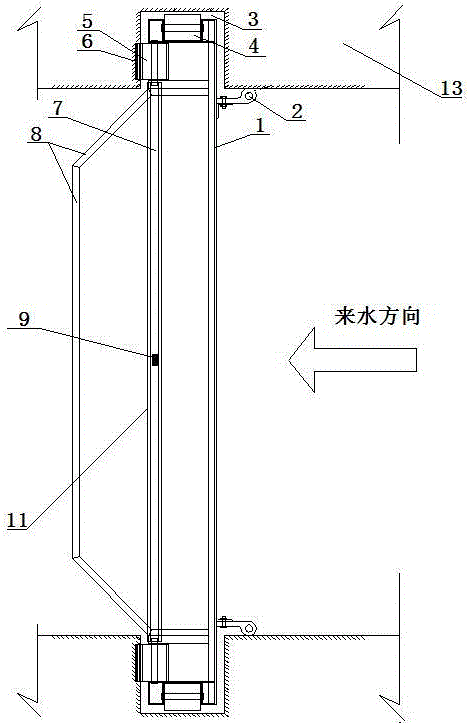

[0008] Referring to the accompanying drawings, a synchronous lifting gate includes a gate 10, the gate 10 is provided with a hook 9, the gate 10 is provided with a water retaining panel 1 and a backwater panel 11, the two sides of the gate 10 are arranged in the gate groove 3, the gate The water retaining panel 1 of 10 is provided with a side water stop 2 and a bottom water stop, and the back water panel 11 is provided with a main truss 8. The rack 6 has a toothed surface facing upstream, and the installation positions and elevations of the two racks 6 are the same. The gears 5 are arranged symmetrically on both sides of the backwater panel 11 of the gate 10, and the gears 5 on both sides are connected by a rigid synchronous shaft 7. The synchronous through shaft 7 is fixed on the backwater panel 11 of the gate 10 through the shaft support frame 12, the positions of the gear 5 and the rack 6 are corresponding, and the gear 5 can walk on the rack 6. The number of the gears 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com