Multistage fracturing horizontal well inter-crack interval CO2 flooding oil extraction method

A horizontal well and fracturing technology, which is applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of inability to quantitatively evaluate the total oil production and oil production, low production efficiency, and many production processes, etc. Achieving good development effect, improving production status, and rationally allocating production and injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content of the present invention, the present invention will be described in detail below in conjunction with specific examples.

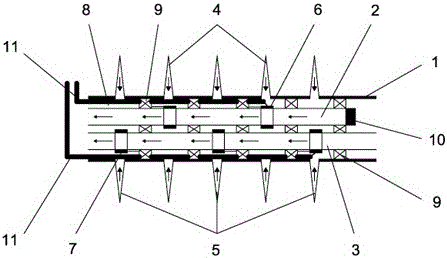

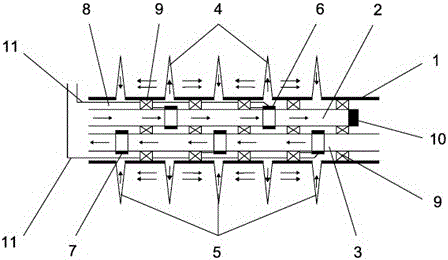

[0031] like figure 1 and figure 2 As shown, according to the multi-stage fracturing horizontal well fracture interval CO of the present invention 2 An embodiment of the oil flooding recovery method, it comprises the following steps in sequence:

[0032] Step 1: Fracturing the wellbore of the horizontal well in stages to form multiple fracturing fractures perpendicular to the wellbore of the horizontal well;

[0033] Step 2: Install tubing I2 and tubing II3 in the casing 1 in the wellbore of the horizontal well, install flow controller I6 on the tubing I2 corresponding to the even-numbered fracture 4, and install the flow controller I6 on the tubing II3 corresponding to the odd-numbered fracture 5 Install the flow controller II7, and set the packer 9 in the annular space 8 of the oil casing corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com