A Downhole Mechanical Hydraulic Pulse Generator

A technology of hydraulic pulse and generating device, applied in vibration generating device, wellbore/well components, production fluid, etc., can solve the problems of hindering the flow of crude oil into the wellbore channel, reducing the permeability of crude oil, poor oil fluidity, etc., so as to improve the flow of crude oil. The effect of stability, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

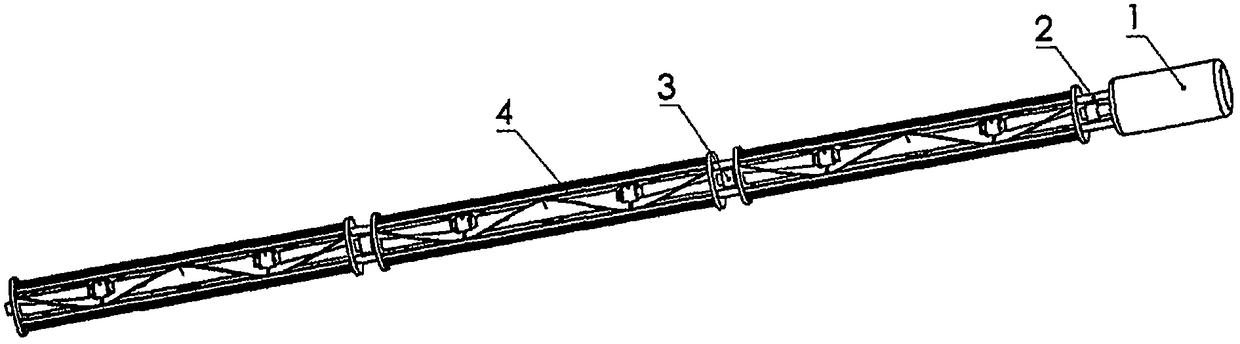

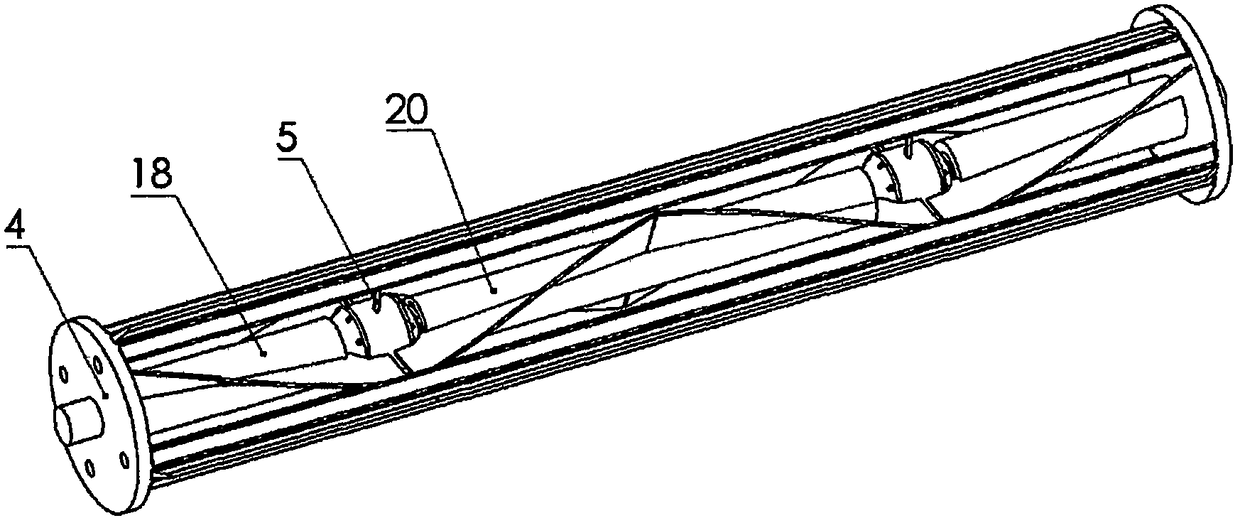

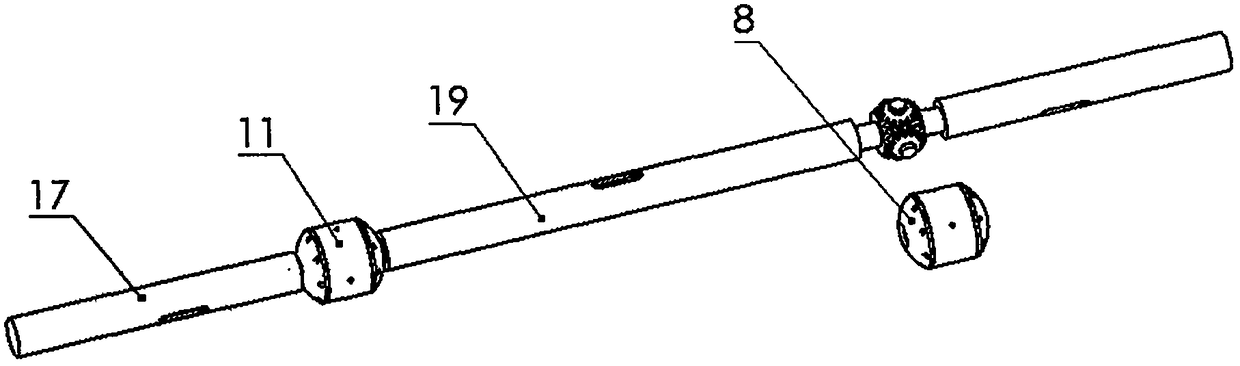

[0035] Depend on figure 1 , figure 2 Shown is a downhole mechanical hydraulic pulse generating device for generating low-frequency hydraulic oscillations on the fluid in the oil and gas well casing. The entire multi-stage mechanical hydraulic pulse generating device is composed of a motor 1 and a plurality of mechanical pulse generating units. The mechanical pulse generating The connecting rods 2 and couplings 3 are connected in series between the units and between the motor and the mechanical pulse generating unit. Each mechanical pulse generating unit is composed of an outer cylinder 4, a gearbox, a planetary bevel gear set, a half-length rotor, and a full-length rotor: the inside of the outer cylinder is used to place the gear box, half-length rotor, and full-length rotor, and the shafts at both ends of the outer cylinder The holes are used to place the half-length rotor, and the full-length rotor is placed between the two half-length rotors. The half-length rotor and the...

Embodiment 2

[0043] A downhole mechanical hydraulic pulse generating device for generating low-frequency hydraulic oscillations on the fluid in the oil and gas well casing, the same as in Embodiment 1, the difference is that the blades of the half-length blade 18 and the full-length blade 20 are flat plates, and the The mechanical pulse generating unit is arranged in a straight shape, and the motor has the same hydraulic oscillation pressure regardless of whether it is in forward rotation or reverse rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com