Two-piece one-die forming method for mutually symmetrical characteristic pieces

A characteristic and symmetrical technology, applied in the field of two-piece one-mold forming, can solve the problems of difficulty in guaranteeing the forming quality of parts, high manufacturing cost, and long R&D cycle, etc., and achieve shortened train production time, low manufacturing cost, and faster filling space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

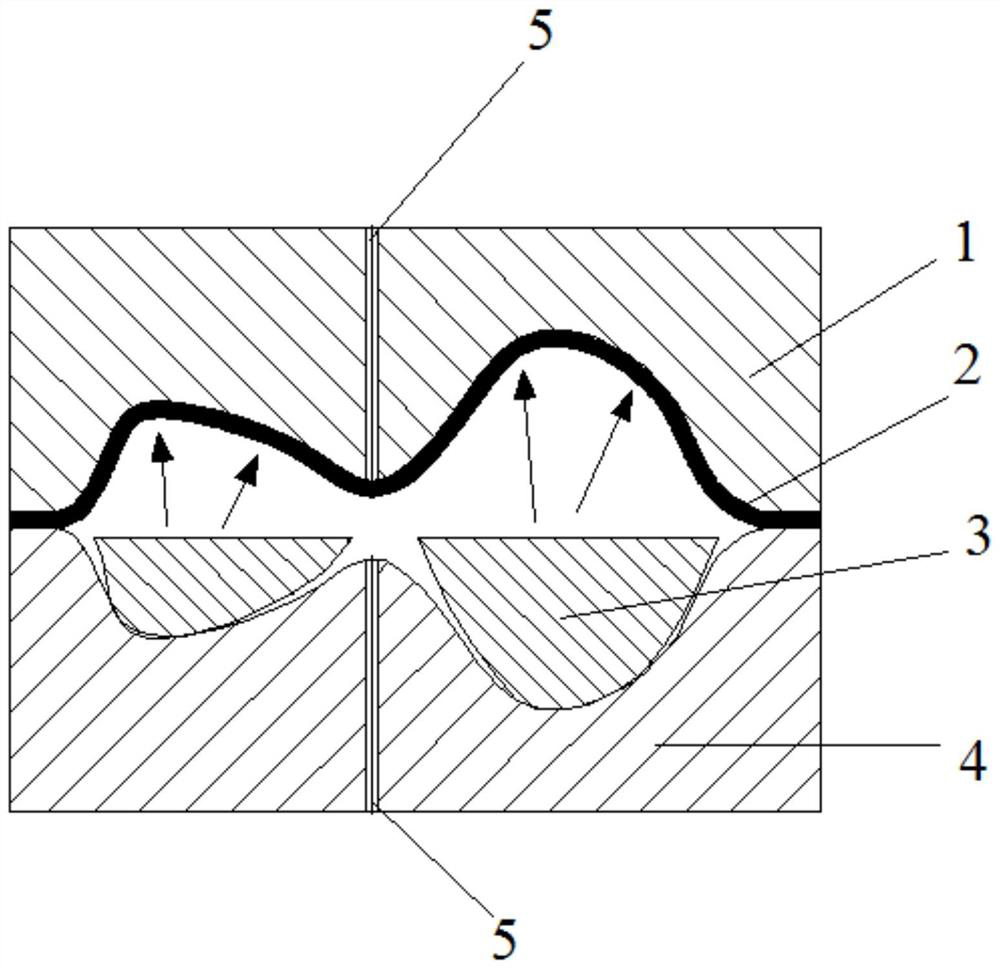

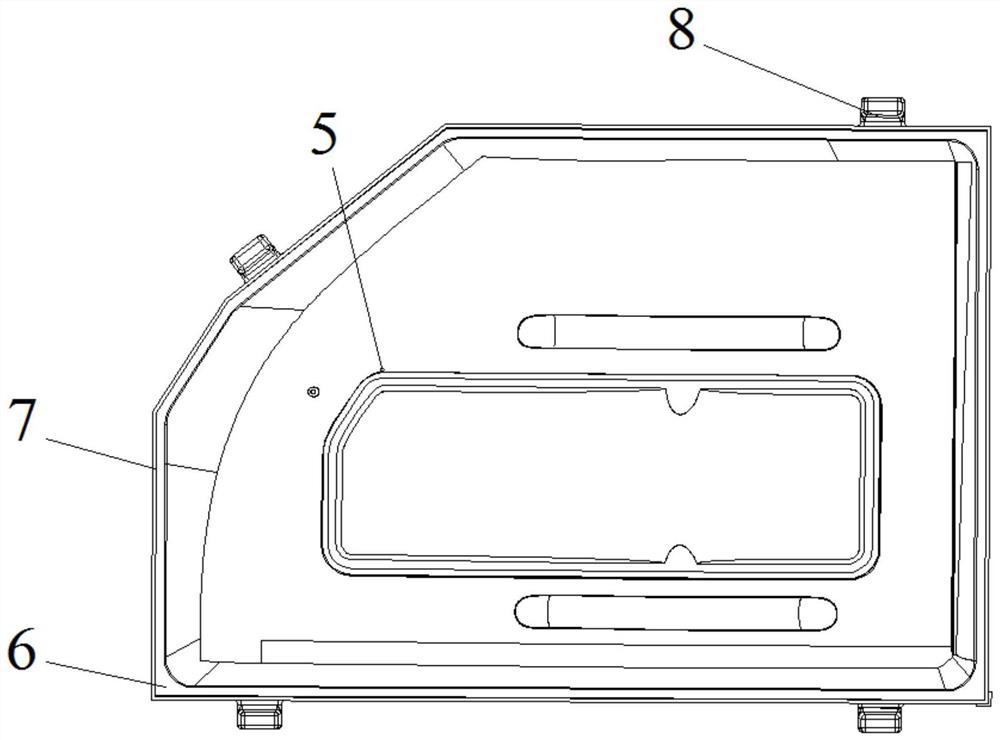

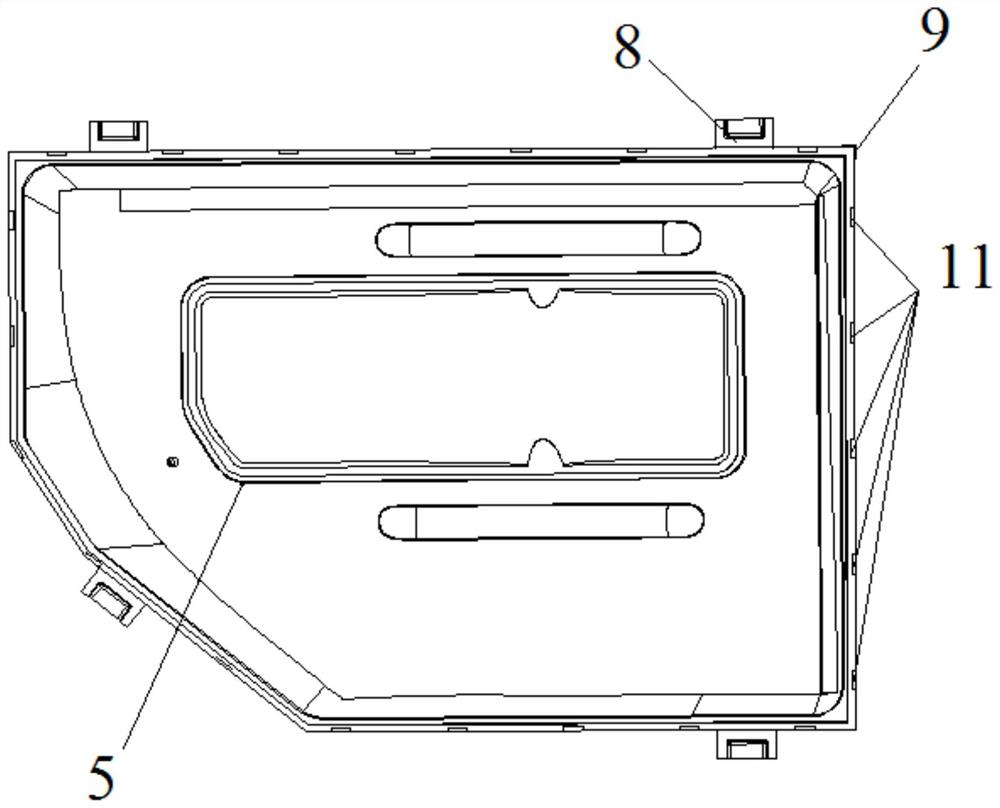

[0035] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment, this embodiment provides a kind of two-piece one mold forming method that is used as symmetrical feature part, described method is carried out through the following steps:

[0036]Step 1: Design the mold: For two large aluminum alloy skin panels with shallow cavities that are symmetrical in space, first design the upper mold 1, determine the cavity size according to the surface shape of the part, and consider the effects of thermal expansion and contraction, and ensure that the edge banding platform 6 It is completely on a plane parallel to the press table, and the basic shape of the lower mold 4 can be obtained with respect to the mirror image of this plane. On this basis, the edge banding platforms 6 in the upper mold 1 and the lower mold 4 are respectively provided with misaligned edge banding grooves 7. A guide mechanism 8, a positioning reference block 9, a thermocouple hole ...

specific Embodiment approach 2

[0045] Specific implementation mode two: refer to Figure 1 to Figure 4 This implementation mode is described. This implementation mode is to further limit the step one described in the first specific implementation mode. In this embodiment mode, the depth of the shallow cavity provided in the large aluminum alloy skin cover in the first step is less than 200mm. Other compositions and connection methods are the same as those in Embodiment 1.

[0046] With such a setting, considering the application range of inflatable forming, if the required depth of the shallow cavity is too large, it will be difficult for inflatable forming to meet the requirements. At the same time, the continuous expansion of the gas will lead to stress on the shallow cavity area of the large aluminum alloy skin cover. Uneven, easy to affect the forming effect.

specific Embodiment approach 3

[0047] Specific implementation mode three: refer to Figure 1 to Figure 4 Describe this embodiment, this embodiment is to further limit the step 1 described in the second specific embodiment, in this embodiment, in the mold structure in the step 1, both the upper mold 1 and the lower mold 4 need to have an air inlet The plane of hole 5 and edge banding platform 6 is parallel to the press platform, and square sealing grooves need to be designed on both the upper mold 1 and the lower mold 4. The two sealing grooves must be misaligned. A jaw 11 is designed every 400mm on the edge banding platform 6 in the middle and the edge banding platform 6 in the lower mold 4 . Other compositions and connection methods are the same as those in the second embodiment.

[0048] In this way, the offset setting of the sealing grooves in the two molds can effectively ensure that the sheet material can fully flow into the upper and lower edge sealing grooves, so that both sides have a good airtight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com