Glass formula applicable to production of glass fiber textile yarns

A technology of glass fiber and textile yarn, which is applied in the field of glass fiber glass formula, can solve the problems of low tensile strength of glass fiber and cannot meet the performance requirements of high-performance glass fiber textile yarn, achieve stable mechanical strength and chemical stability, and improve The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

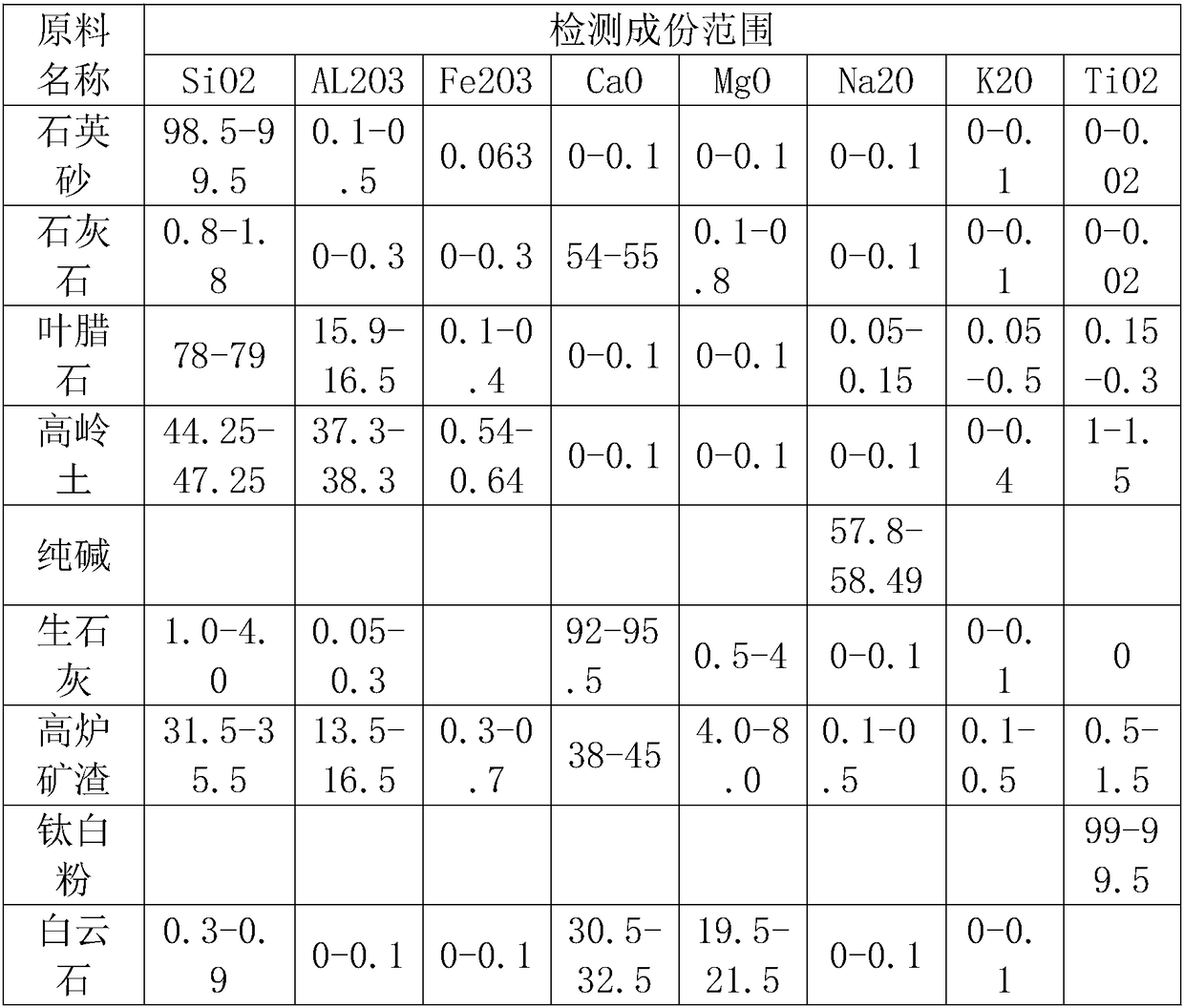

[0033] The technical solution of the present invention will be further described through specific examples below, but the scope of protection of the present invention is not limited thereto: the raw materials used in the glass formula are: pyrophyllite powder, purchased from Shandong Fiberglass Group Company; quicklime powder, purchased from CITIC Calcium Industry Company; dolomite powder, purchased from Linyi Jinou Company; kaolin, purchased from Zibo Yuanjia Company; quartz powder, purchased from Yinan Xinrun Silicon Industry Company; limestone, purchased from Sishui Jinhai Company; blast furnace slag, purchased from Lai Steel Group; titanium dioxide, purchased from Jinan Yuxing Company. The ingredients range of each raw material is as follows:

[0034] Table 1

[0035]

[0036] Preparation steps:

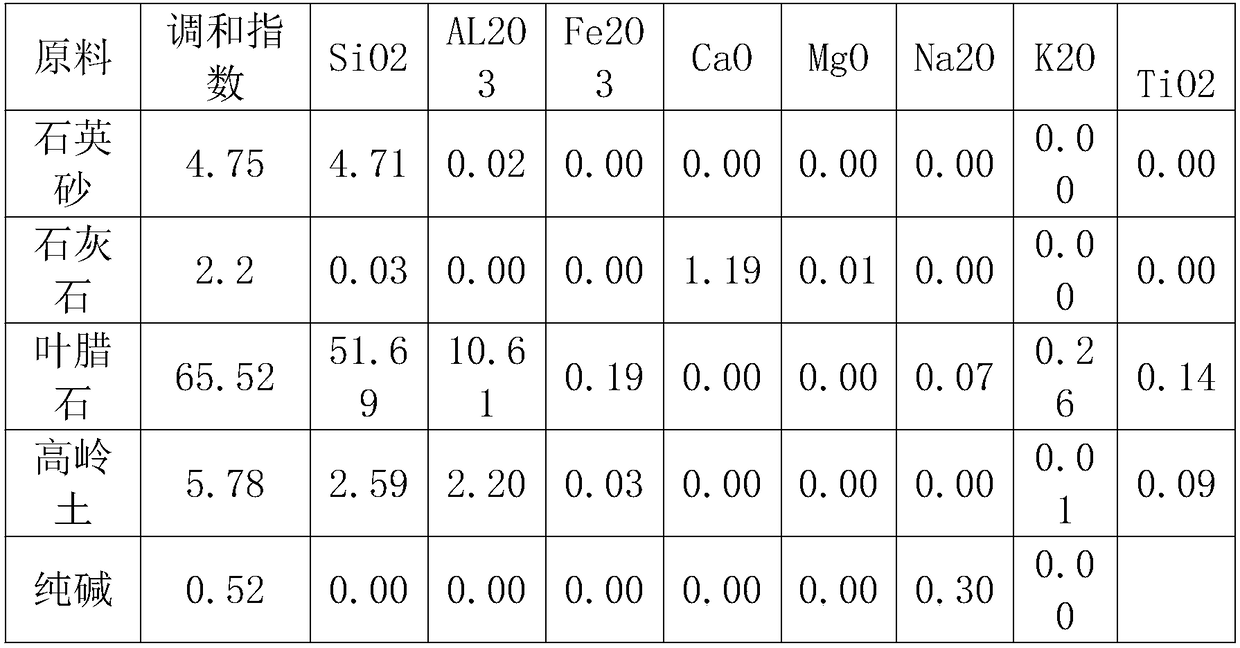

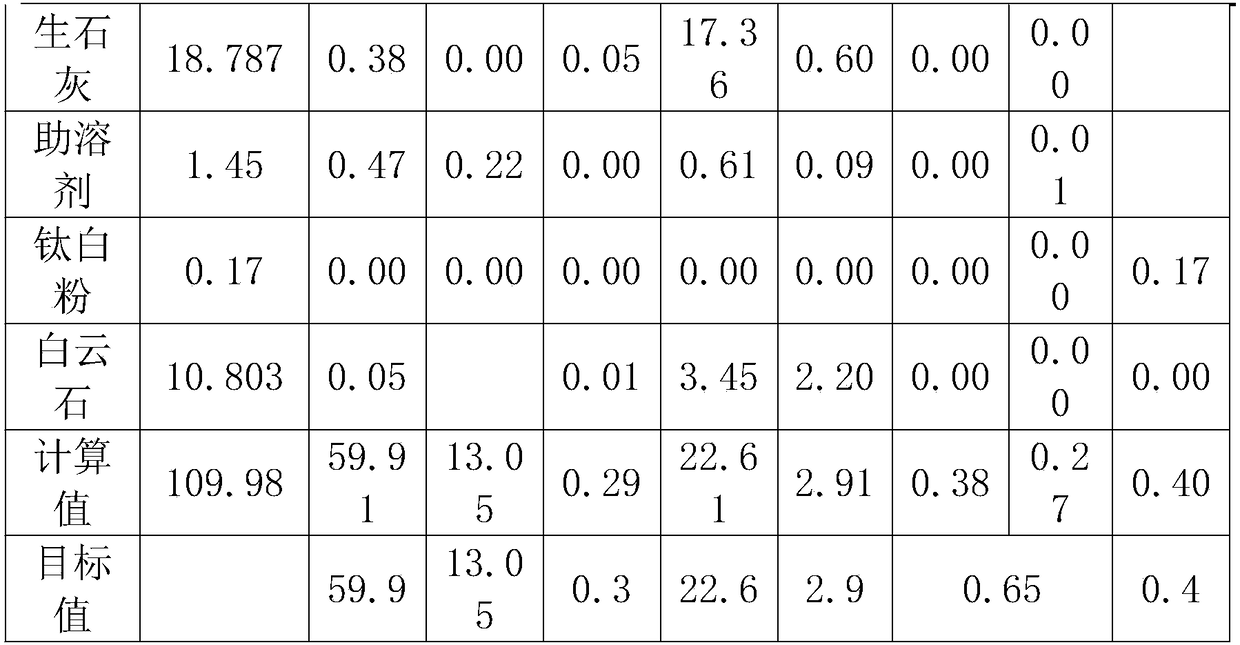

[0037] According to the design of: SiO2: 59.9%, Al2O3: 13.05%, Fe2O3: 0.3%, CaO: 22.6%, MgO: 2.9%, Na2O+K2O: 0.65%, TiO2: 0.4%, the raw materials are mixed Proportioning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com