A Diaphragm Coupling with Axial Elastic Limitation

A technology of elastic limit and diaphragm, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

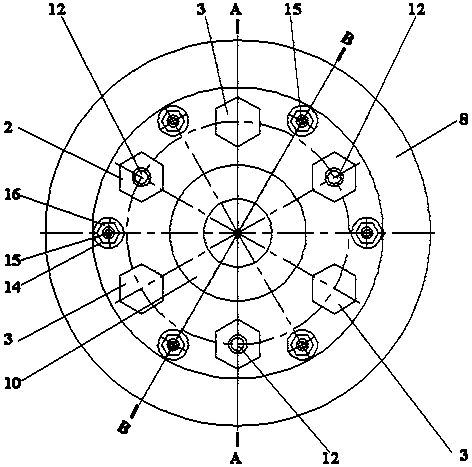

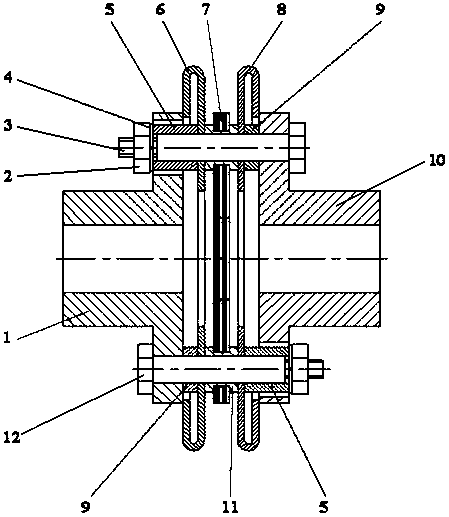

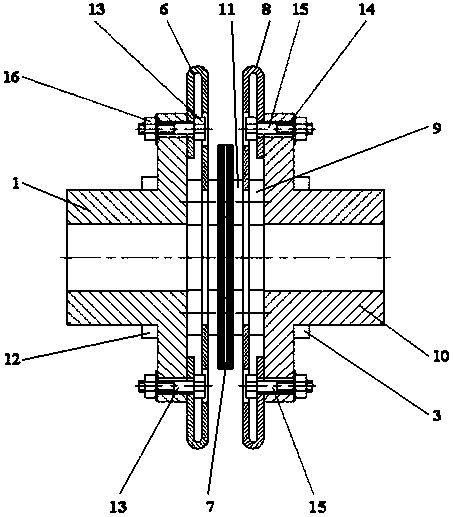

[0022] Embodiment 1, reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 . It can be seen from the drawings that a diaphragm coupling with axial elastic limit is composed of the first half coupling 1, the diaphragm fixing nut 2, the first diaphragm fixing bolt 3, the diaphragm fixing bolt gasket 4. The movable end elastic limit piece positioning sleeve 5, the first elastic limit piece 6, the diaphragm group 7, the second elastic limit piece 8, the fixed end elastic limit piece positioning sleeve 9, the second half coupling 10 , Diaphragm group fixing pin 11, second diaphragm fixing bolt 12, first elastic limiting plate fixing bolt 13, elastic limiting plate fixing bolt gasket 14, second elastic limiting plate fixing bolt 15, elastic limiting plate The fixed nut 16 is composed of; its characteristic is that the diaphragm group 7 and the diaphragm group fixing pin 11 are fixedly connected together; , the first elastic limit piece 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com