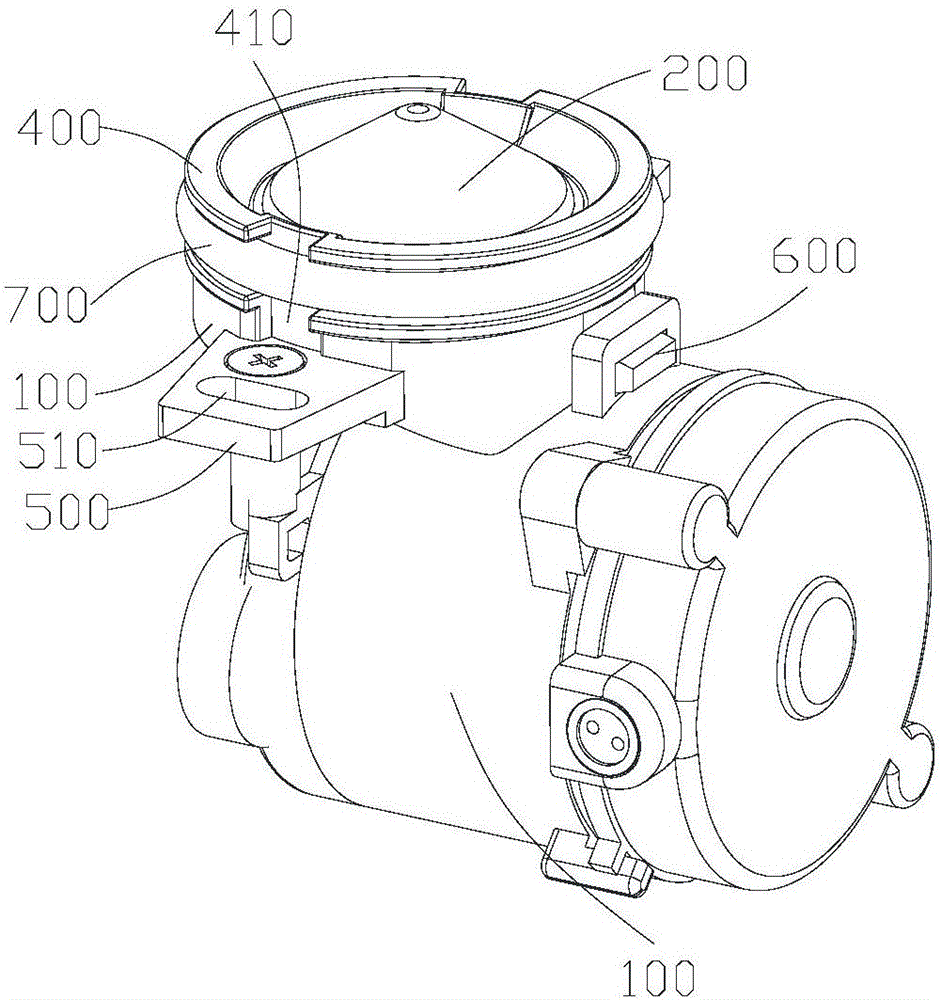

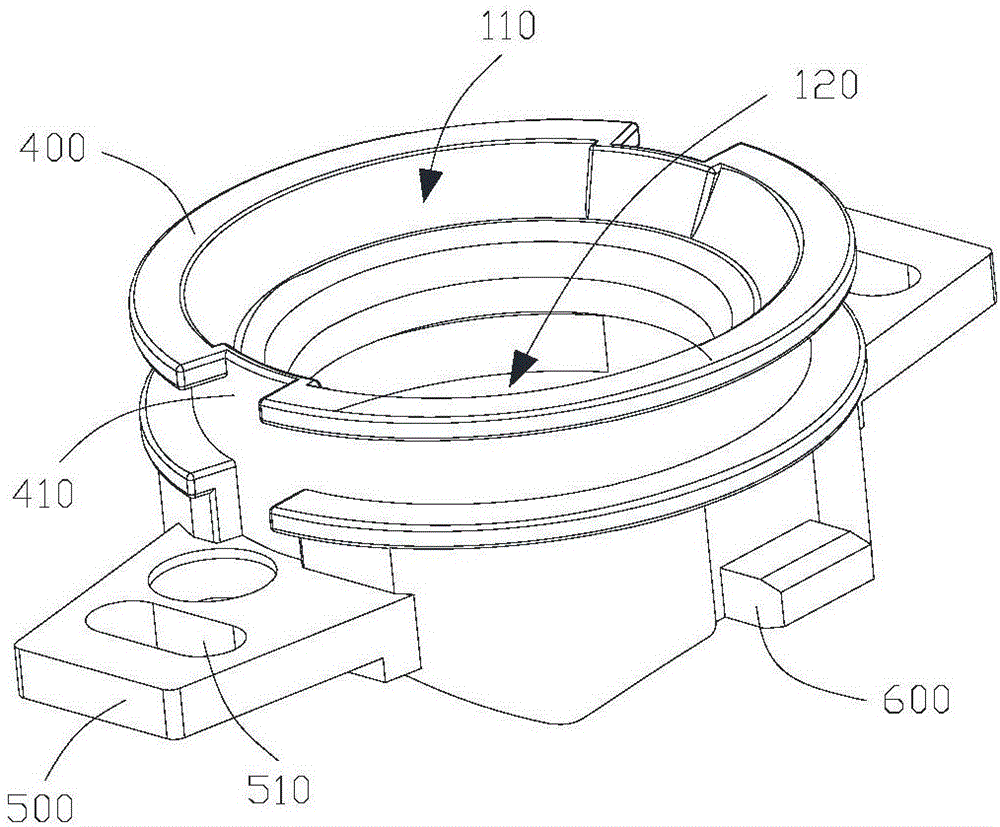

Small-size low-pressure-loss type bidirectional non-blocking rotating gear transmission electromechanical valve and gas meter

A technology of low pressure loss and gear rotation, applied in the direction of engine components, lift valves, valve details, etc., can solve the problems of electromechanical valves with large volume, large volume, and cannot be installed on aluminum gas meters, etc., and achieve small installation space and wide range , The effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060] see Figure 5-Figure 6, this embodiment also provides a small low-pressure loss type two-way non-stall gear transmission electromechanical valve, this embodiment is a further improvement on the basis of the technical solution of the first embodiment, and the disclosed technical solution of the first embodiment is also applicable In this embodiment, in order to avoid repetitive and cumbersome descriptions, the technical solutions already described in Embodiment 1 will not be described in detail.

[0061] Specifically, the driving mechanism includes an eccentric mechanism, a transmission rod 930, and a transmission sleeve 940. The driving end of the eccentric mechanism drives and connects the transmission sleeve 940. The rotation of the eccentric mechanism makes the transmission sleeve 940 move linearly, and the transmission sleeve 940 is connected to the sealing cap to drive The sealing cap moves linearly synchronously. Further, the eccentric mechanism includes a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com