A refrigerant circulation system and its control method

A refrigerant circulation system and refrigerant technology, applied in the direction of fluid circulation arrangements, refrigerators, refrigeration components, etc., can solve the problems of limited opening adjustment ability and small adjustment range of electronic expansion valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

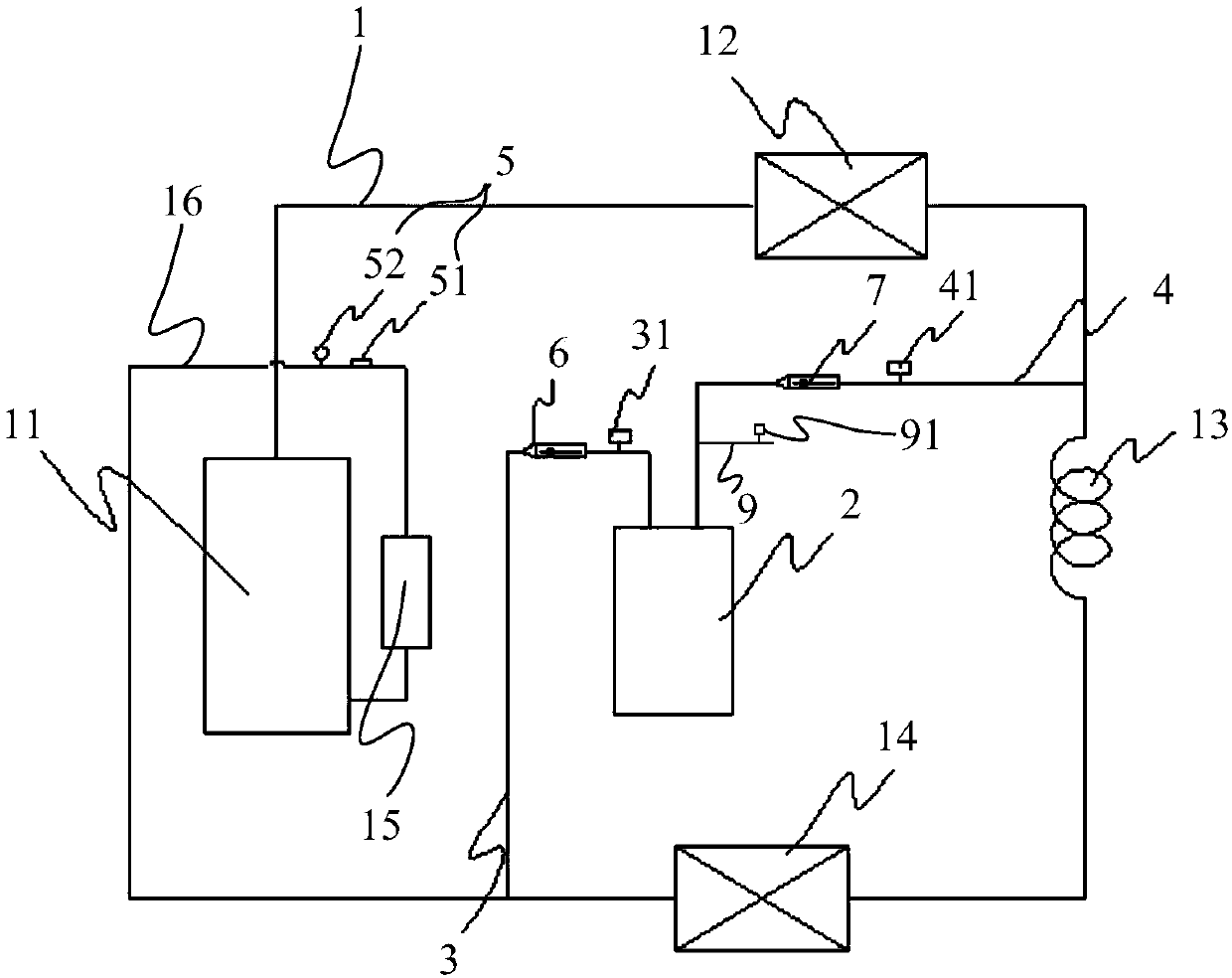

Embodiment 1

[0027]Embodiment 1: The detection system 5 includes a first temperature detection unit (not shown in the figure), a second temperature detection unit (not shown in the figure) and a third temperature detection unit 51, the first temperature detection unit is used to detect evaporation The temperature T1 of the refrigerant at the inlet of the evaporator 14, the second temperature detection unit is used to detect the temperature T2 of the refrigerant in the middle of the pipeline of the evaporator 14, the third temperature detection unit 51 is used to detect the temperature T3 of the refrigerant in the return air pipe 16 of the compressor, and the second The first temperature detection unit, the second temperature detection unit and the third temperature detection unit 51 are all connected to the control unit. Therefore, if T2-T1>0, that is, the temperature of the refrigerant in the middle of the pipeline of the evaporator 14 is greater than the temperature of the refrigerant at ...

Embodiment 2

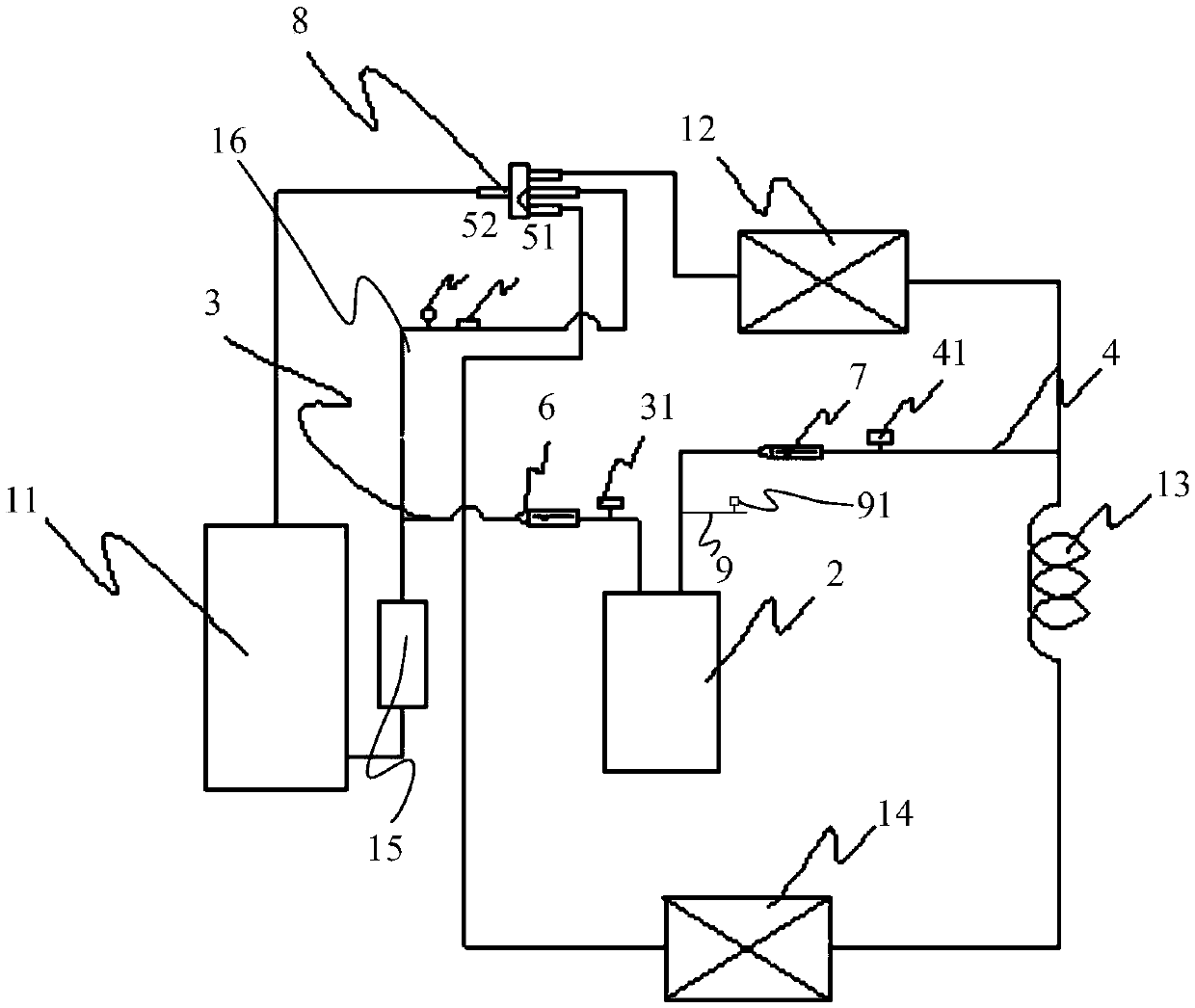

[0033] Embodiment 2: The detection system 5 includes a pressure detection unit 52 for detecting the refrigerant pressure in the air return pipe 16 of the compressor, and the pressure detection unit 52 is connected with the control unit. Therefore, if P is less than the minimum value within the preset threshold range, it means that the refrigerant in the refrigerant circulation circuit 1 is insufficient, and the control unit determines that the refrigerant in the refrigerant circulation circuit 1 is insufficient, and controls to open the charging valve 31 to circulate the refrigerant. The circuit 1 is filled with refrigerant. After opening the charging valve 31, if P is within the preset threshold range, the control unit closes the charging valve 31 to complete the charging process; if P is greater than the maximum value within the preset threshold range, It means that there is too much refrigerant in the refrigerant circulation circuit 1, and the control unit determines that th...

Embodiment 3

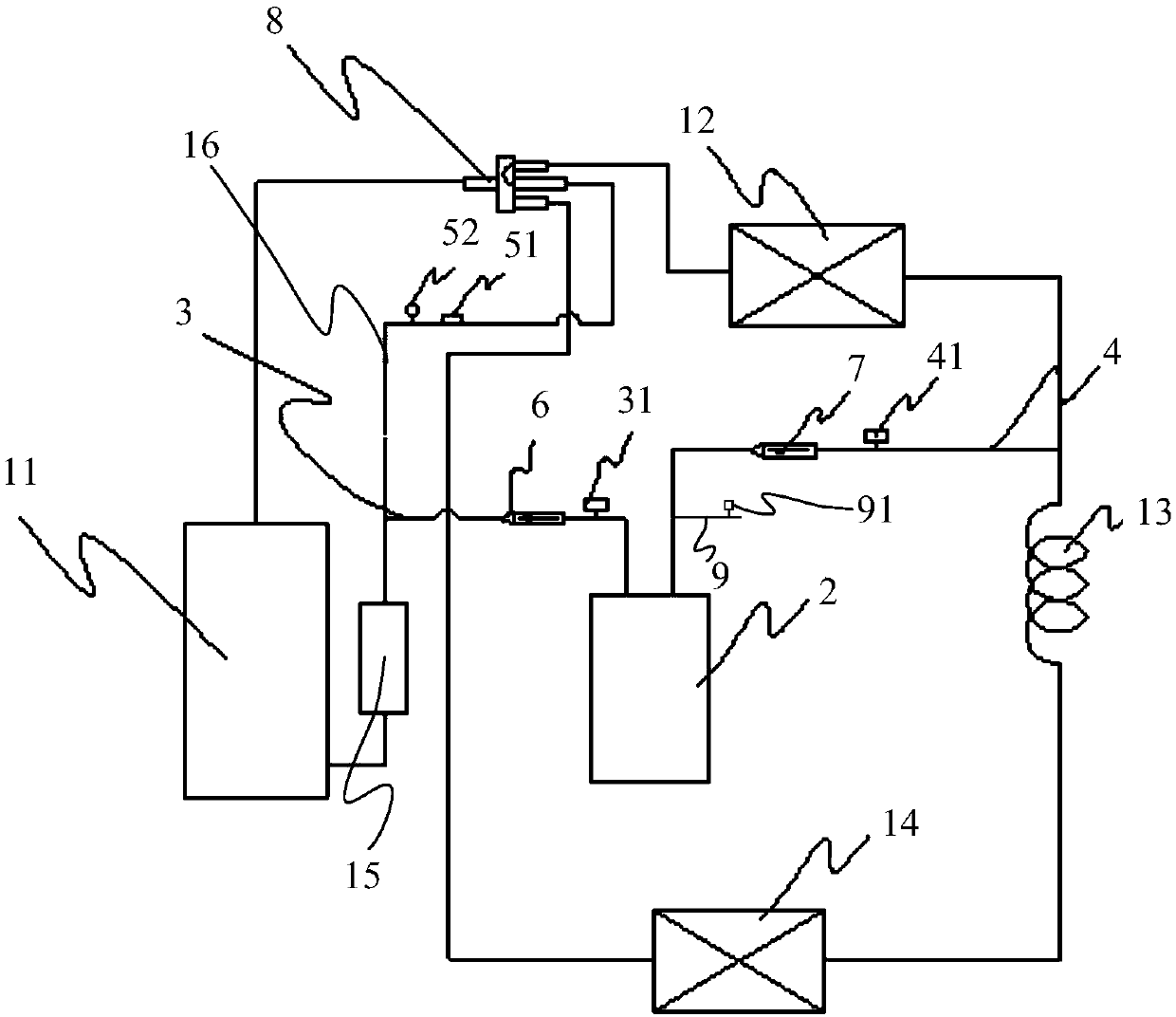

[0036] Embodiment 3: The detection system 5 includes a first temperature detection unit, a second temperature detection unit, a third temperature detection unit 51 and a pressure detection unit 52, the first temperature detection unit is used to detect the temperature T1 of the refrigerant at the inlet of the evaporator 14, The second temperature detection unit is used to detect the temperature T2 of the refrigerant in the middle of the pipeline of the evaporator 14, the third temperature detection unit 51 is used to detect the temperature T3 of the refrigerant in the return air pipe 16 of the compressor, and the pressure detection unit 52 is used to detect the return temperature of the compressor. The refrigerant pressure P in the gas pipe 16, and the first temperature detection unit, the second temperature detection unit, the third temperature detection unit 51 and the pressure detection unit 52 are all connected to the control unit. Therefore, if T2-T1>0, it means that the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com