An in-situ shearing device and installation method for obtaining rock and soil strength parameters

A shearing device, a technology of rock and soil mass, applied in the direction of measuring device, strength characteristics, testing material strength by applying a stable shearing force, etc., can solve the unbalanced force of shearing ring, test failure, insufficient normal pressure and other problems to achieve the effect of solving adverse effects, convenient assembly and disassembly, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, they are only examples, and the advantages of the present invention will become clearer and easier to understand.

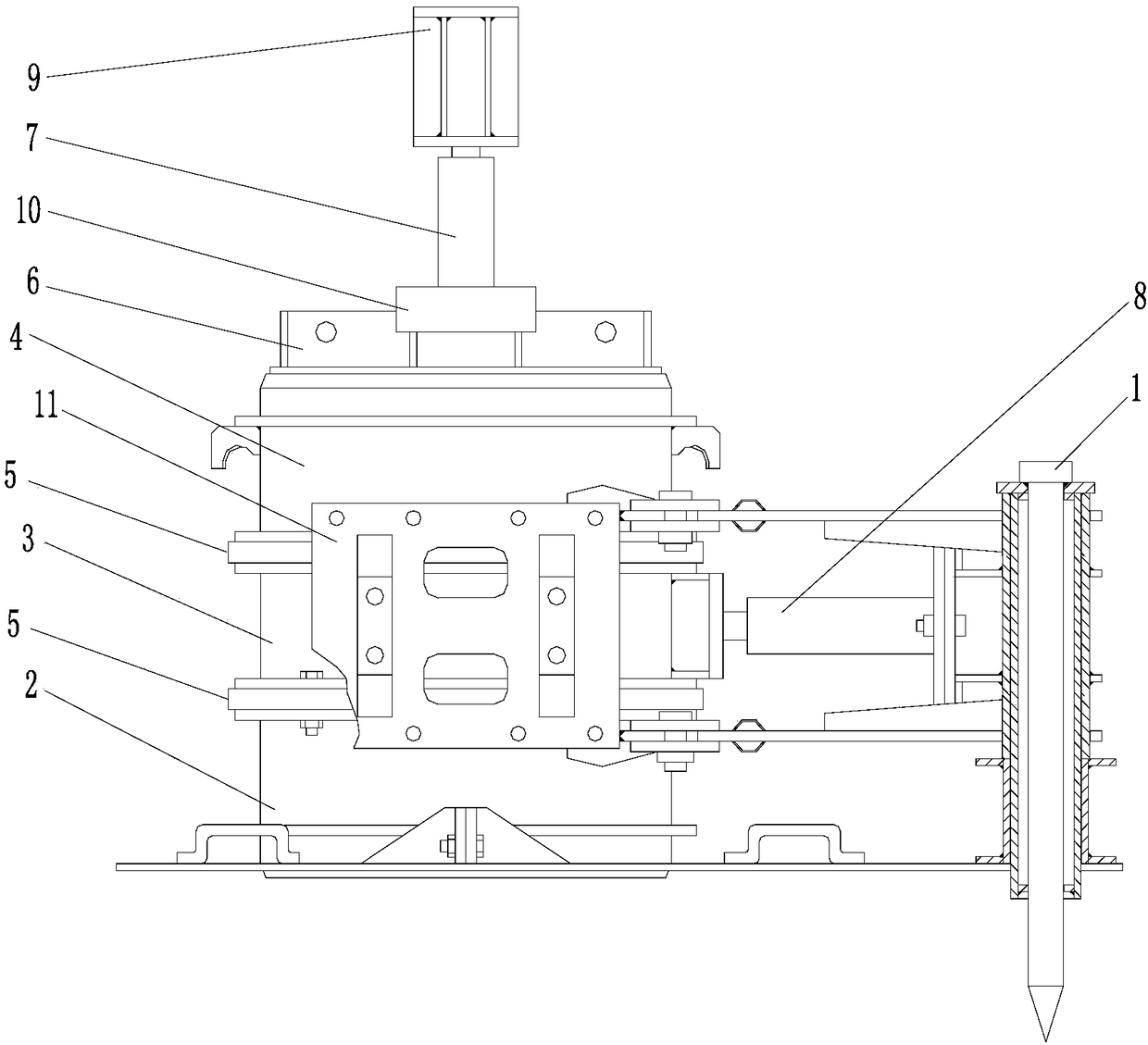

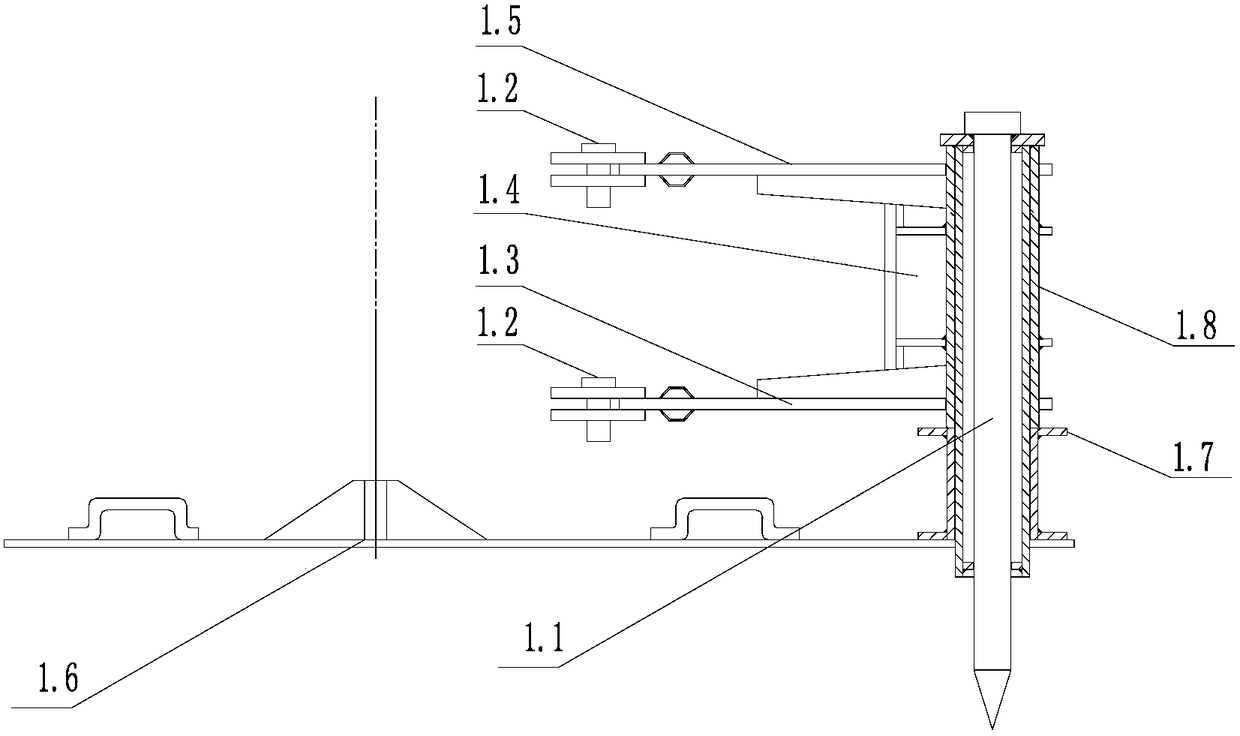

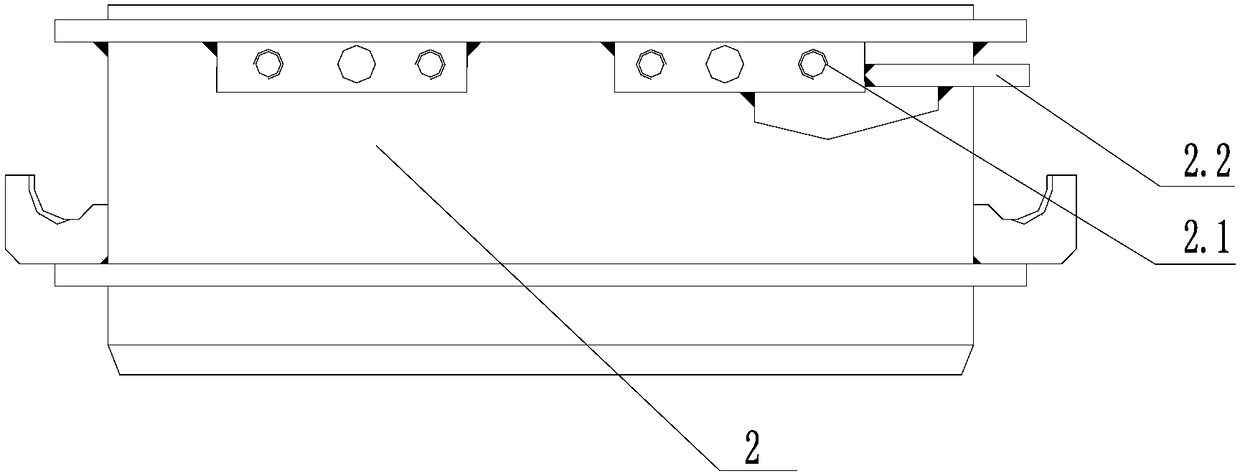

[0059] refer to Figure 1-12 Described: the present invention is an in-situ shearing device and installation method for obtaining rock and soil strength parameters, which is characterized in that: a slotted lining tile 5 is placed between the circular upper ring 4, the middle ring 3 and the lower ring 2, Side guide rails 11 are installed on both sides of the upper ring 4 and the lower ring 2, a ring bolster 6 is installed on the upper end of the upper ring 4, and a ball is installed on the ring bolster 6. Head 10, a vertical jack 7 is installed on the ball head 10, and a small beam 9 is installed on the top of the vertical jack 7; a horizontal jack 8 is arranged direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com