Device for spraying contamination onto surface of insulator uniformly

A technology with uniform surface and insulators, which is applied in the field of uniform contamination on the surface of insulators in the artificial pollution discharge test of insulators. It can solve the problems of uneven pollution on the surface of insulators, affecting the pollution level of discharge characteristics, etc., and achieve low noise, prevent slipping, and precise control of speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

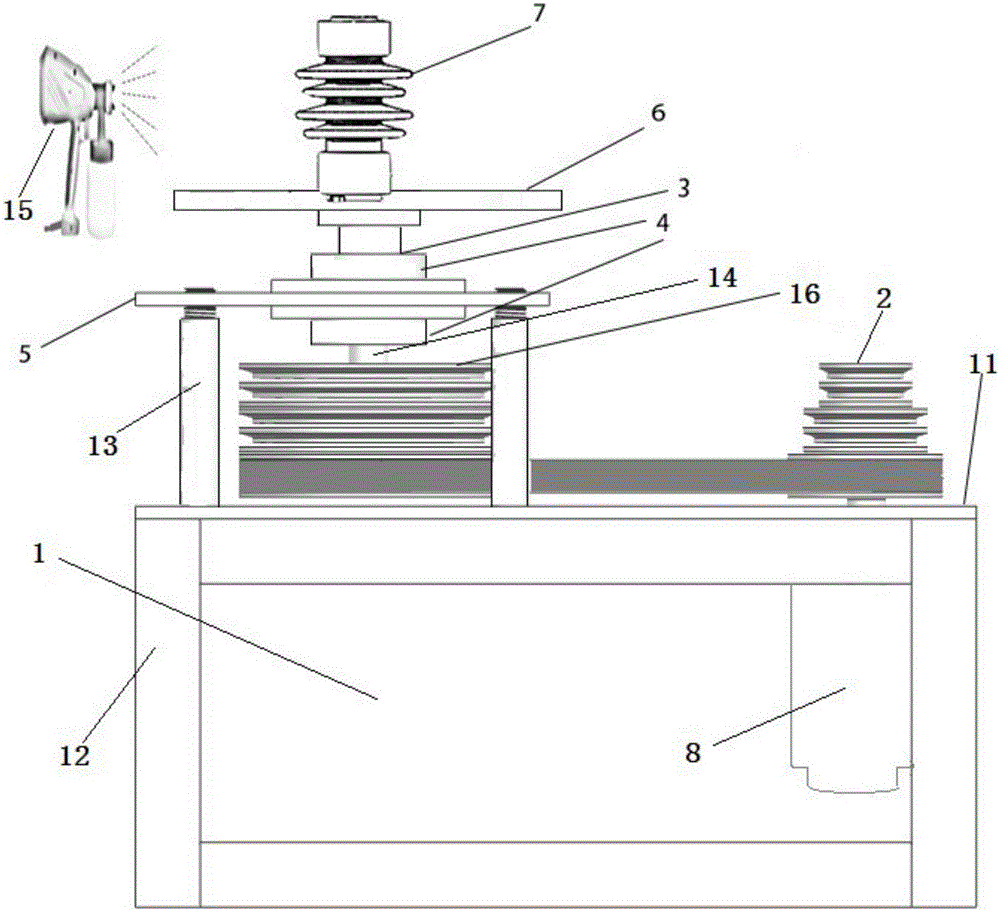

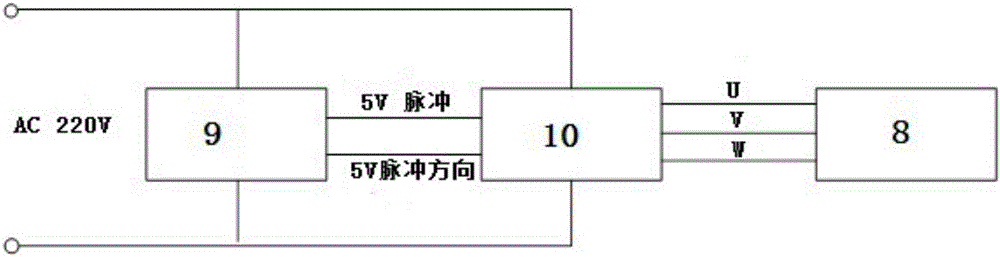

[0031] A device for spraying dirt evenly on the surface of an insulator, such as figure 1 Shown, comprise platform, stepping motor 8, driving wheel 2, driven wheel 16, loading plate 6 and dirt sprayer 15. The stand includes a motor mounting table 1 and a support plate 5. The motor mounting table 1 is composed of a stand leg 12 and a table top 11. The table top 11 is provided with a first through hole. The stepping motor 8 is arranged under the table top 11, and the output shaft passes through The through hole is connected with the driving wheel 2, the support plate 5 is arranged on the table top 11 through the support plate legs 13 (four screw rods), the support plate 5 is provided with a second through hole, and the driven wheel 16 is arranged between the support plate 5 and the table top 11 Between them, a shaft body 14 is provided at the axis of the driven wheel 16, and the shaft body 14 is arranged vertically. 5 Rotational connection, the carrier board is provided with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com