Optical fiber connector plug

An optical fiber connector, optical fiber contact technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of loose fiber connector plug and socket thread, failure of optical interconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

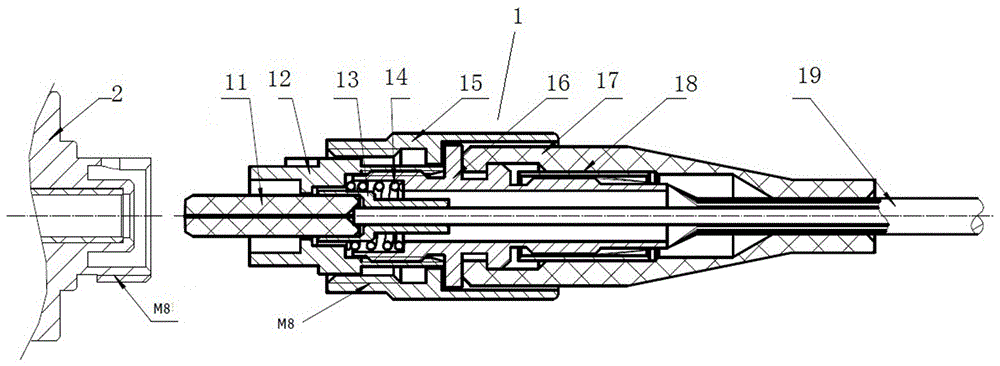

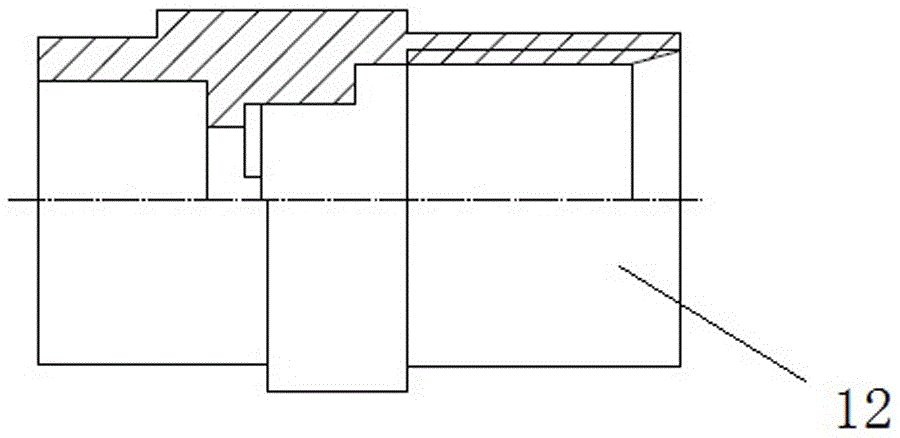

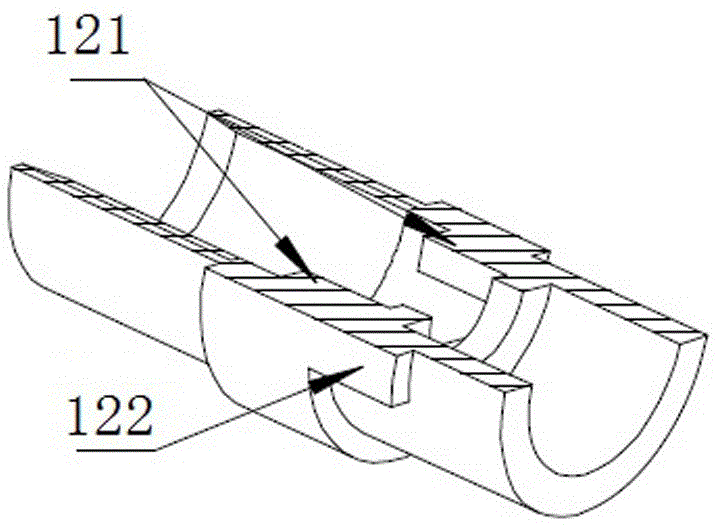

[0044] The embodiment of optical fiber connector plug of the present invention: as Figure 4-28As shown, the fiber optic connector plug includes a front sleeve, a rear sleeve 14, a connecting nut 8, and an optical fiber contact. The optical fiber contact piece includes a ceramic ferrule 20 , a flange 21 and an optical cable 24 arranged at its tail end, and the rear sleeve 14 is connected with a sheath 12 sleeved on the optical cable. The front cover includes a cover body 3, and a key block 4 fixed on the outside of the cover body through a fixed structure for guiding and preventing rotation with the corresponding socket housing. Groove 33, anti-rotation groove 33 has two that 180 degree intervals are arranged, as interior keyway. The sleeve body 3 is provided with an annular boss arranged around its axis, and the annular boss is provided with a positioning keyway 34 for positioning the installation position of the key block on the outer periphery of the sleeve body along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com