Watch with replaceable watchband

A watch strap and watch technology, applied in the field of watches, can solve problems such as inconvenient installation and disassembly, easy damage, and inability to freely deform, and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

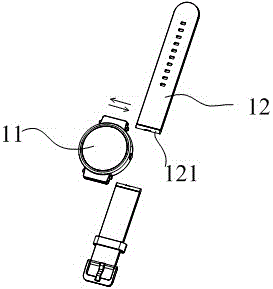

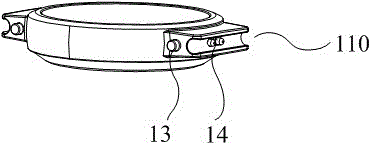

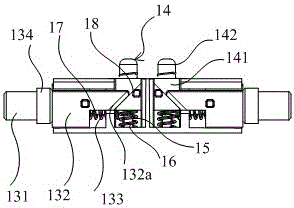

[0026] Embodiment 1, this embodiment proposes a watch with a replaceable strap, such as figure 1 , figure 2 As shown, it includes a watch body 11 and a watch strap 12. The watch body 11 is provided with an outwardly opening socket slot 110, and the end of the watch strap 12 is provided with a plug joint 121. The two sides of the groove 110 have arc edges turned inward respectively, and the plug joint 121 is inserted into the socket 110 along the extension direction of the socket 110. The watch body 12 is also provided with a release module, which includes a release button 13 And the snap tongue 14, the side wall of the insertion slot 110 has a snap tongue groove, the snap tongue 14 is arranged in the snap tongue groove, and the front end of the plug joint 121 has a limit slot matched with the snap tongue. In the natural state, the tongue 14 protrudes from the tongue groove into the insertion groove 110, and when the release button 13 is pressed, the tongue 14 is retracted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com