On-line Cooperative Compensation Method for Follow-up and Contour Errors

A technology of contour error and follow-up error, which is applied in the field of precise, efficient and intelligent CNC machining, can solve the problems that the stability of the system is difficult to be effectively guaranteed, the estimation accuracy is difficult to guarantee, and the effect of contour control is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation of the present invention will be described in detail in conjunction with the technical solution and the drawings.

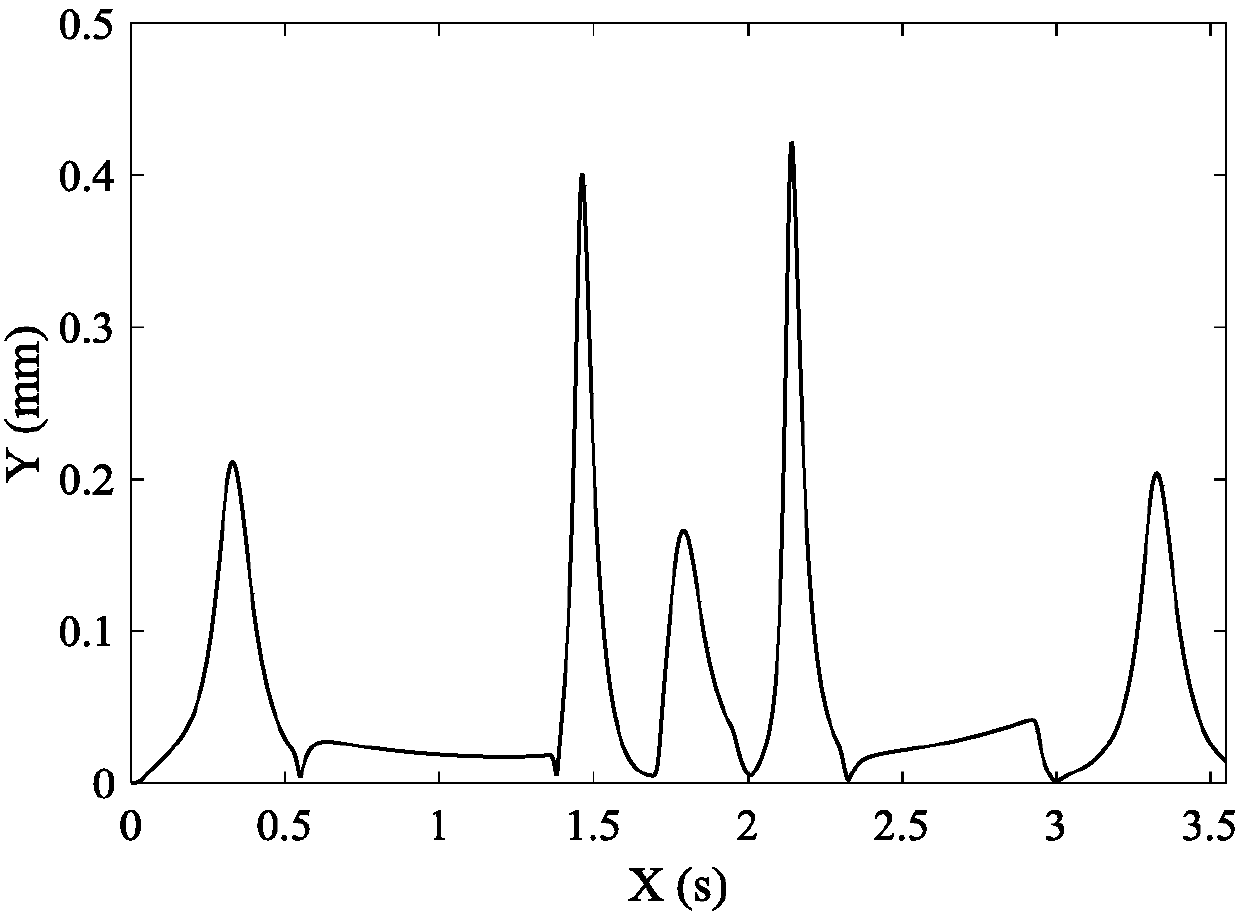

[0059] In the process of parameter curve direct interpolation, due to the hysteresis characteristics and dynamic performance mismatch of each feed axis servo control system, large single-axis motion following errors and multi-axis linkage contour errors will be caused, in order to improve the processing contour Accuracy, invented an online coordinated compensation method for follow-up and contour errors.

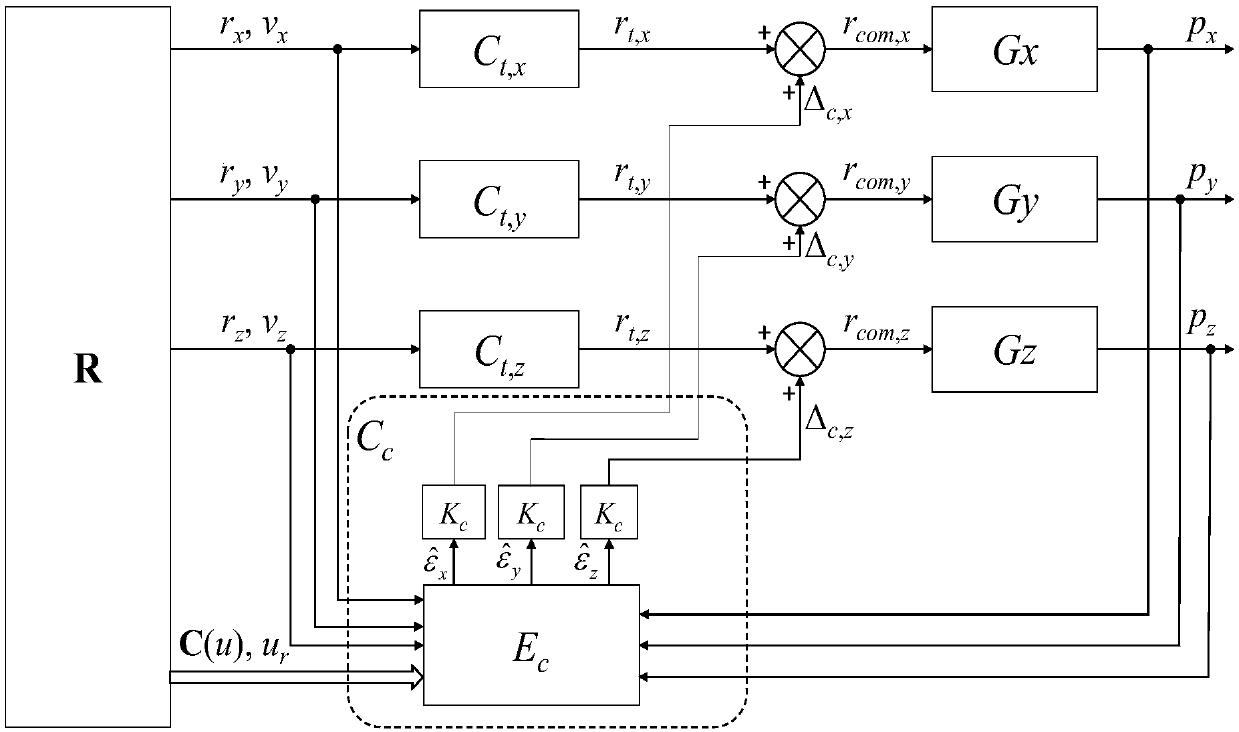

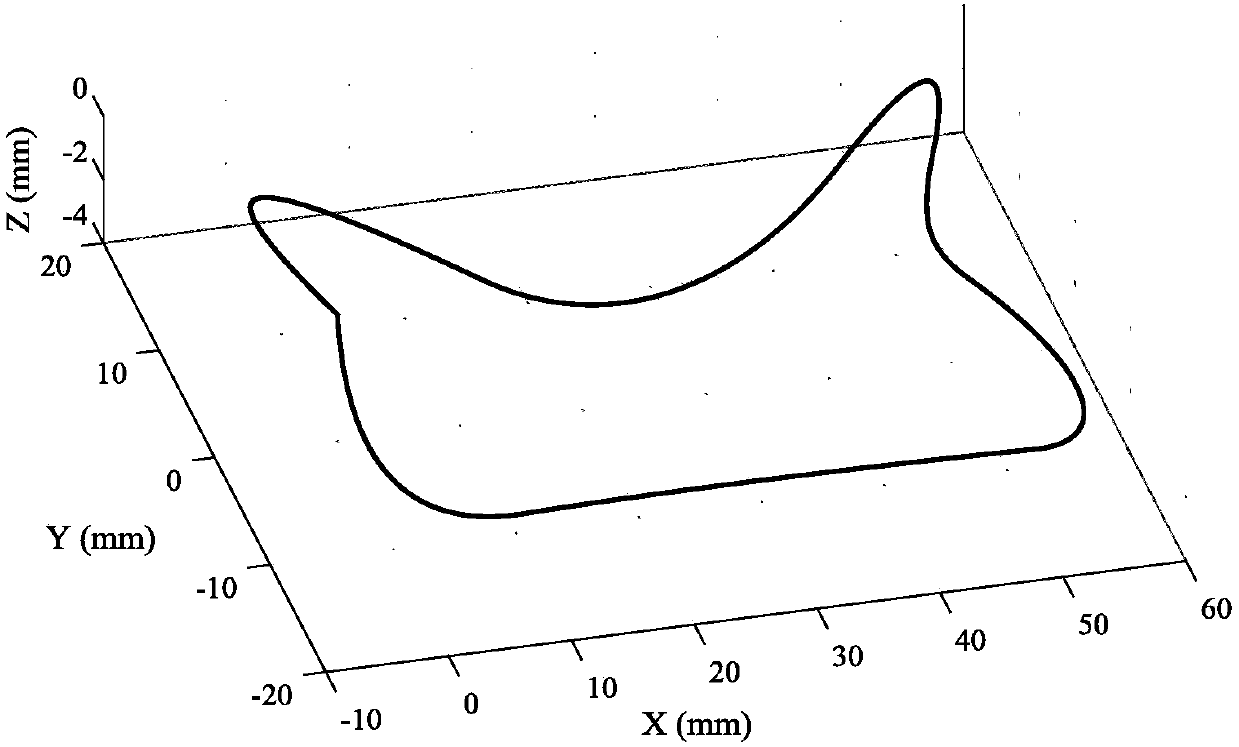

[0060] Attached figure 1 Schematic diagram of follow-up and contour error compensator, attached figure 2 It is the geometric model of the curve tool path, attached figure 2 The shown non-uniform rational B-spline curve tool path contour is taken as an example to describe the specific implementation process of the present invention in detail. The non-uniform rational B-spline parameter of the curve tool path contour is: order: 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com