L5 connector structure for low-noise cable and connection method

A connection method and connector technology, applied in the direction of testing/measuring connectors, connections, and connecting device components, etc., can solve problems such as failure of low-noise cables, unusability, damage to vibration data, etc. break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

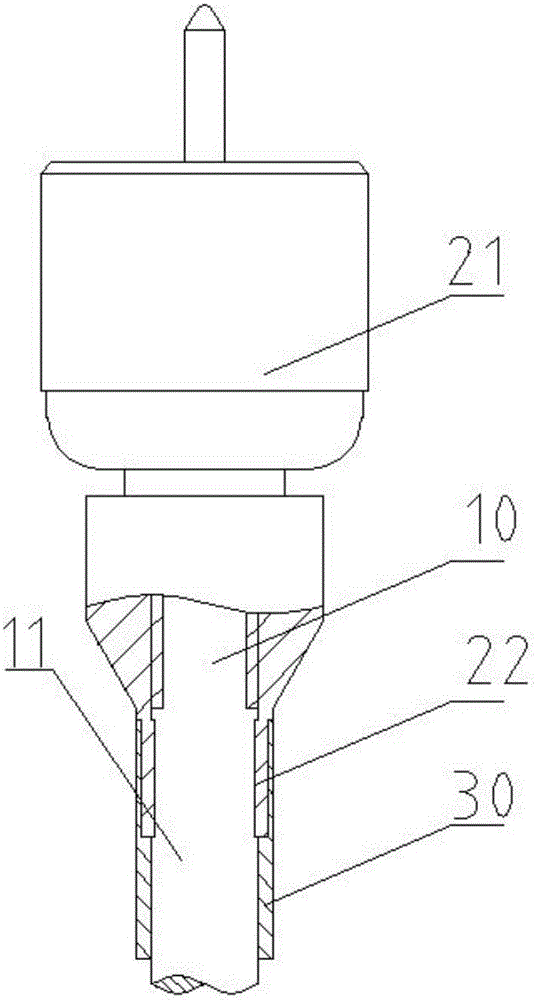

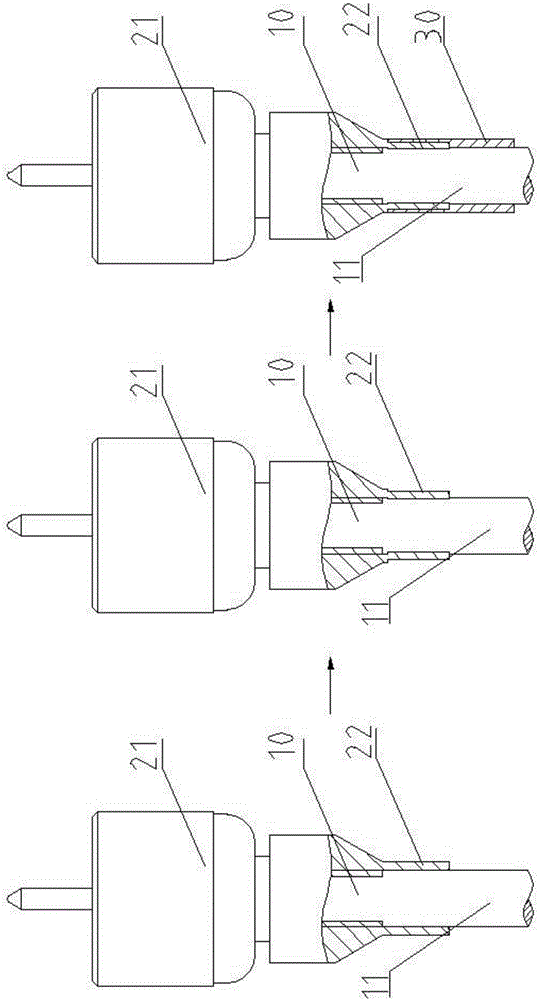

[0021] see figure 1 with figure 2 , as shown in the legend therein, a low-noise cable L5 connector structure, the above-mentioned cable 10 includes a cable core wire (not shown in the figure), a cable shielding layer (not shown in the figure) and a cable sheath 11, the above-mentioned cable The shielding layer is wrapped on the outside of the above-mentioned cable core wire, and the cable sheath 11 is wrapped on the outside of the cable shielding layer. The above-mentioned L5 connector includes a connector plug 21, a connector pin (not shown in the figure) and a connector sleeve 22, The above-mentioned connector pin is connected with the inner hole of the connector plug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com